Harmonic suppressor

A harmonic suppressor and cavity technology, applied in waveguide devices, electrical components, circuits, etc., can solve the problems of limited depth of stop band suppression, low power capacity of suspended strip line harmonic suppressors, and inability to fine-tune, etc. Achieve the effect of high passband cut-off frequency, simple structure and convenient debugging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

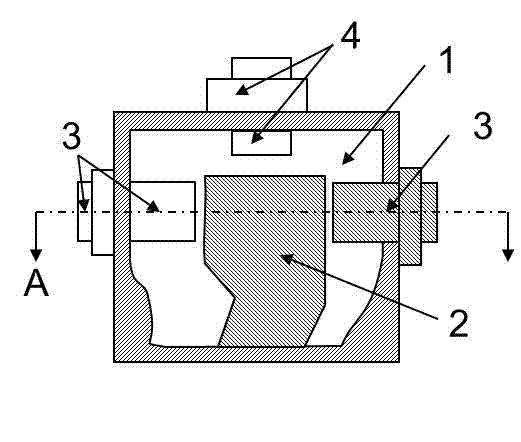

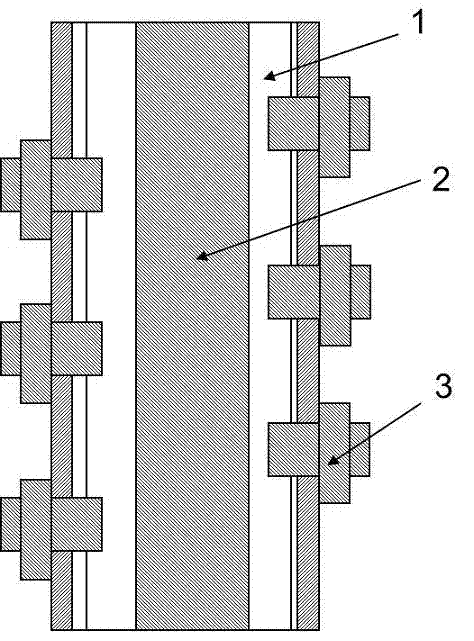

[0037] As it is figure 1 , 2 As shown, a harmonic suppressor includes a metal cavity 1, an inner conductor 2 and at least three frequency-modulating metal columns 3, the metal cavity 1 is a columnar cavity structure placed horizontally, and the axis of the metal cavity 1 is in line with the horizontal line Parallel, the inner conductor 2 is a columnar structure placed horizontally, the inner conductor 2 is arranged inside the metal cavity 1, and the bottom surface of the inner conductor 2 is connected to the bottom inner wall of the metal cavity 1; 1 is inserted into the metal cavity 1.

[0038] In order to generate a transmission zero point in the stop band of the harmonic suppressor to improve the stop band suppression steepness of the low-pass filter, the frequency-modulating metal posts 3 are alternately arranged on the left and right sides of the inner conductor 2 along the axial direction of the inner conductor 2, The depth at which the frequency-modulating metal post ...

Embodiment 2

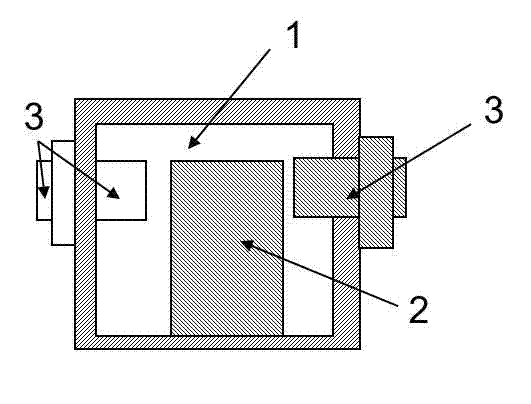

[0048] Such as image 3 with 4 As shown, the difference between this implementation example and the first implementation example is that: the cross-sectional shape of the inner conductor 2 is rectangular, and the shape of the axis of the metal cavity 1 and the inner conductor 2 is U-shaped, and the positive shape of the inner conductor 2 is There is no matching metal post 4 inserted above.

Embodiment 3

[0050] Such as figure 2 with 5 As shown, the difference between this implementation example and the first implementation example is that the cross-sectional shape of the inner conductor 2 is T-shaped.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com