Full-load commercial vehicle platform and modularization application thereof

A commercial vehicle, full-loading technology, applied in the direction of load-bearing body structure, vehicle components, superstructure, etc., can solve the problems of easy deformation of the vehicle body, heavy weight of the vehicle body, inability to open the cargo door, etc., to improve the loading and unloading efficiency and level. , reduce operating costs, the effect of light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

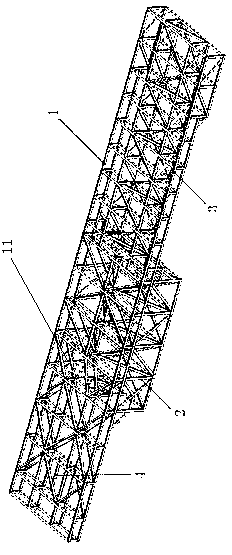

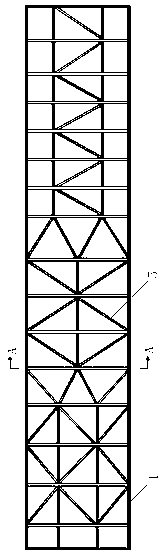

[0026] see figure 1 , a full-load commercial vehicle platform, the full-load commercial vehicle platform includes a car body skeleton, the car body skeleton includes a plurality of transverse facets and a plurality of longitudinal facets, and the intersection of the transverse facets and the longitudinal facets generates The nodes of are connected with the corresponding nodes of the adjacent facets to form the car body skeleton of the multi-dimensional triangular space frame structure. The skeleton structure of the car body is mainly composed of transverse facets and longitudinal facets. When the longitudinal facets containing several triangles and polygons are combined with the transverse facets, multiple intersection nodes will be formed. When the car body is subjected to loads, all end nodes participate in the transmission of the load, thereby forming a multi-dimensional force flow field space, making the car body a multi-dimensional closed force loop system. The load is ...

Embodiment 2

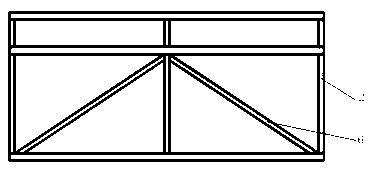

[0028] see figure 1 , 2 , 3. As an improvement of the present invention, the transverse facet includes a triangle or polygon formed by a transverse side beam 1 and a transverse brace 5 or a combination of a triangle and a polygon; the longitudinal facet includes a longitudinal side beam 2 and a longitudinal The triangles or polygons formed by the diagonal braces 6 or the combination of triangles and polygons. according to image 3 In the structure shown, several longitudinal facets of the car body are welded with longitudinal side beams 2, longitudinal braces 6 and frame rods, and then multiple longitudinal assembly and welding are performed after being positioned and clamped by tooling fixtures; and transverse side beams 1 It is welded with the corresponding nodes of the adjacent longitudinal facets to form a unified frame structure; the grid structure with a large span is welded diagonally with horizontal braces 5 to form a figure 2 The horizontal facet shown contains s...

Embodiment 3

[0030] As an improvement of the present invention, the number of the triangles and polygons is at least two. The polygons may be other polygons such as quadrilaterals, pentagons, and hexagons, and may be freely combined and matched according to actual needs. Its structure and advantage are identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com