Separate purification device for processing waste by superconductivity high-gradient magnetic separation (HGMS) technology

A technology for technical treatment and waste, which is applied in the treatment and reuse of acidic heavy metal wastewater, and in the field of separation and purification devices using superconducting HGMS technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

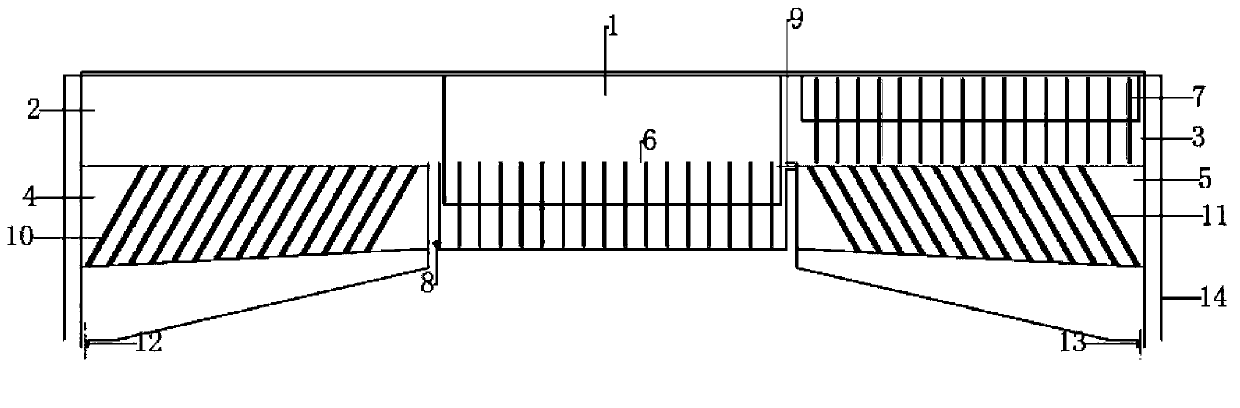

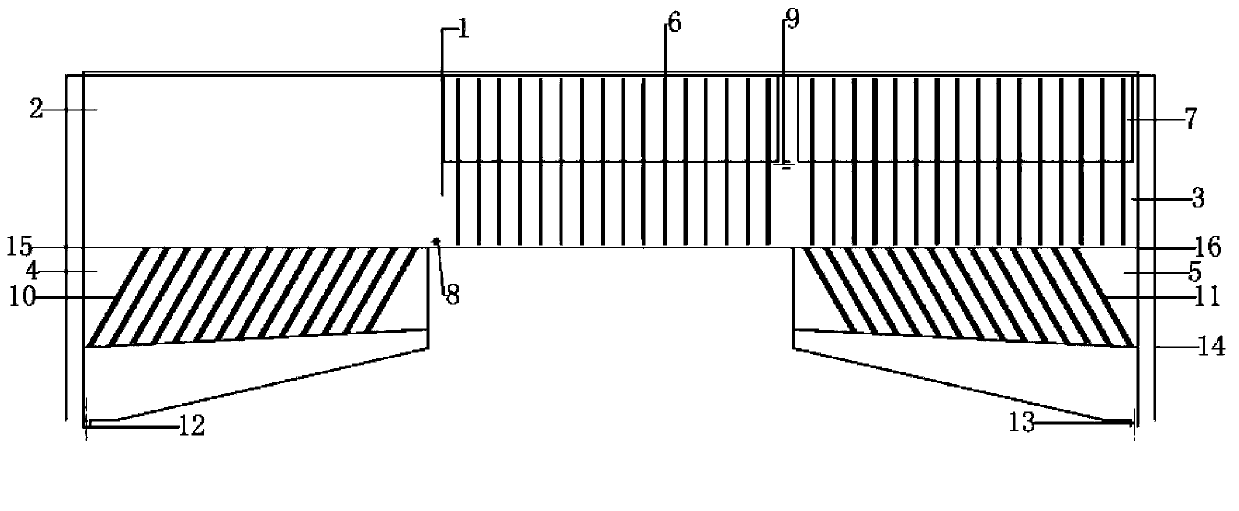

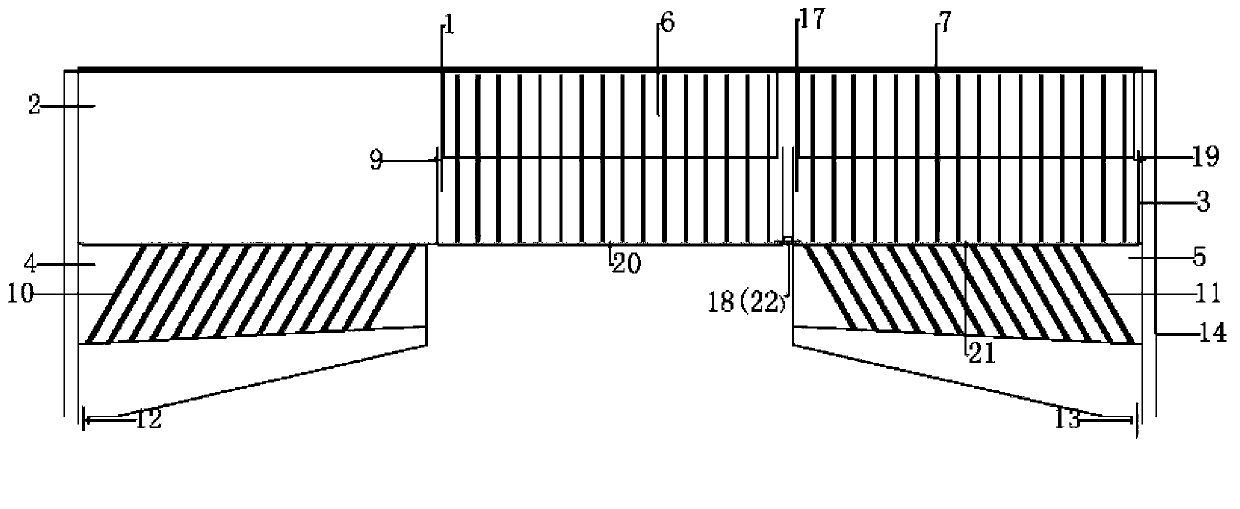

[0020] figure 1 It is a schematic diagram of a separation and purification device for treating waste by using superconducting HGMS technology according to the present invention. The waste water enters the reaction tank one 1 from the water inlet one 8 . The adsorption device 1 6 rotates at a certain speed in the wastewater, and the pollutants in the water are quickly adsorbed by the adsorbent under the action of the superconducting high gradient magnetic field. After the adsorption reaction is completed, the adsorption device-6 is pulled and lifted by the support shaft 14 and moved to the desorption chamber-2 for desorption. The adsorption device 2 7 in the desorption chamber 2 3 is moved to the reaction tank 1 1 to continue treating the wastewater. The treated water is discharged from the water outlet one 9. During the desorption process of the desorption chamber 1 2 , the generated waste water enters the sloping plate sedimentation tank 1 4 . The adsorption device 1 6 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com