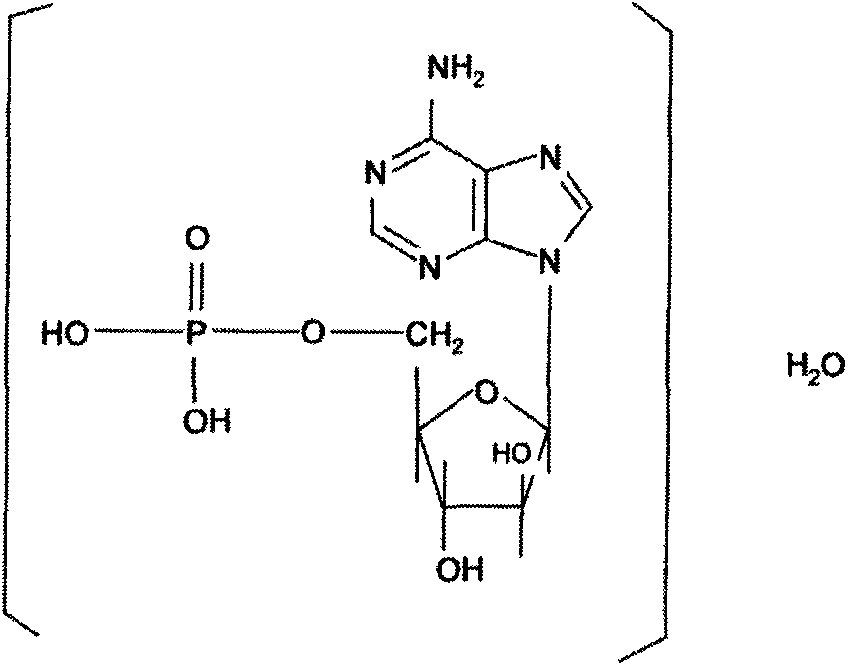

Refining method of vidarabine monophosphate

A technology for vidarabine monophosphate and vidarabine monophosphate crude products, which is applied in the field of medicine and chemical industry, and can solve problems such as high temperature, low product purity and yield, and product instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Under the protection of nitrogen, add 20g of vidarabine monophosphate crude product and 1g of sodium sulfite into 200ml of water, adjust the pH to 9.5 with 2N sodium hydroxide solution, heat to 40°C, stir to dissolve, then add 1g of activated carbon, keep warm at 40°C and stir Decolorize, filter while hot, adjust the filtrate to pH = 4 with 2N sulfuric acid solution, cool to -5 ~ 0°C, stir to crystallize, filter, wash with ice water, and dry to obtain 18.4g of refined vidarabine monophosphate, content 99.94%, refined Yield 92%.

Embodiment 2

[0023] Add 20g of vidarabine monophosphate crude product and 1g of ammonium sulfite into 200ml of water, adjust the pH to 10 with 28% ammonia solution, heat to 40°C, stir to dissolve, then add 0.6g of activated carbon, keep warm at 40°C and stir to decolorize. Filter while it is hot, adjust the filtrate to pH=3.5 with 2N hydrochloric acid solution, cool to -5~0°C and stir to crystallize, filter, wash with ice water, and dry to obtain 18.2g of refined vidarabine monophosphate, content 99.95%, refined yield 91%.

Embodiment 3

[0025] Add 20g of vidarabine monophosphate crude product and 1g of sodium sulfite into 400ml of water, adjust the pH to 8 with 2N sodium hydroxide solution, heat to 40°C, stir to dissolve, then add 1g of activated carbon, keep warm at 40°C and stir to decolorize, while hot Filter and adjust the filtrate to pH=5 with 2N sulfuric acid solution, lower the temperature to -5~0°C and stir to crystallize, filter, wash with ice water, and dry to obtain 17.2g of refined vidarabine monophosphate, the content is 99.96%, and the refined yield is 86% .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com