Cable outlet system for high voltage cable oscillatory wave partial discharge detection system

A technology for partial discharge detection and high-voltage cables, which is used in the measurement of lead wires/probes, dielectric strength measurement, and measurement device casings, etc., which can solve the problems of inconvenient installation and removal, inaccurate detection results, and unstable connections. Achieve the effect of easy disassembly and assembly, favorable field test and no partial discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

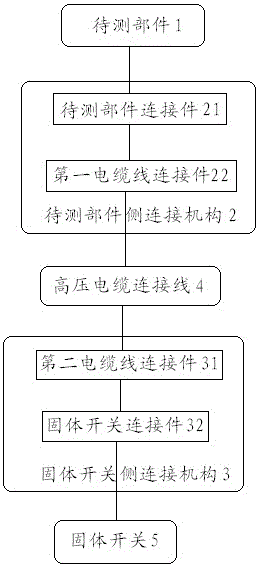

[0034] The structure of a cable outlet system for a high-voltage cable oscillatory wave partial discharge detection system according to the present invention is as follows: figure 1 As shown, it includes a connection mechanism 2 on the side of the component under test, a connection mechanism 3 on the side of the solid switch and a high-voltage cable connection 4, wherein the connection mechanism 2 on the side of the component under test includes a connection part 21 of the part under test and a first cable connection part 22 , the component to be tested connector 21 is connected to the component to be tested 1; the solid switch side connection mechanism 3 includes a solid switch connector 32 and a second cable connector 31, and the solid switch connector 32 is connected to the solid switch 5; The two ends of the high-voltage cable connecting wire 4 are respectively connected to the first cable connecting piece 22 of the connecting mechanism 2 on the part under test side and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com