GaAs pseudomorphic high electron mobility transistor

A high electron mobility, transistor technology, applied in the direction of circuits, electrical components, semiconductor devices, etc., can solve the problems of degraded transistor performance, uneven pinch-off voltage, poor adhesion, etc., to achieve inhibition of reaction, suppression of gate leakage current, The effect of improving reliability performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing, the present invention is further described in detail:

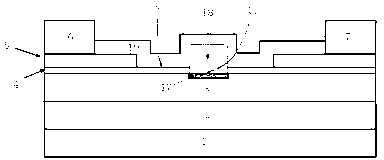

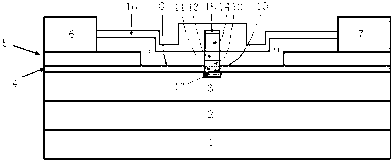

[0027] like image 3 As shown, the present invention relates to a gallium arsenide pseudomorphic high electron mobility transistor, comprising: a substrate 1, an AlGaAs buffer layer 2, a barrier layer 3, a low-doped GaAs layer 4, a highly doped GaAs layer 5, a source An electrode 6 and a drain electrode 7, a first groove 8 is provided between the source electrode 6 and the drain electrode 7, a second groove 10 is provided in the first groove 8, and a metal layer is arranged in the second groove 10. Specifically, the metal layer includes a first gate metal sublayer 11, a second gate metal sublayer 12, a third gate metal sublayer 13, a fourth gate metal sublayer 14, and a fifth gate metal sublayer 15. A barrier metal layer 17 is grown in the barrier layer 3.

[0028] In the present invention, the buffer layer 2 adopts the superlattice periodic structure of Al0.24Ga0.7...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com