Compound semiconductor device and method of manufacturing same

A manufacturing method and semiconductor technology, applied in the direction of semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problems of current collapse, reduce withstand voltage, leakage current, etc., and achieve the goal of suppressing gate leakage current and current collapse. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

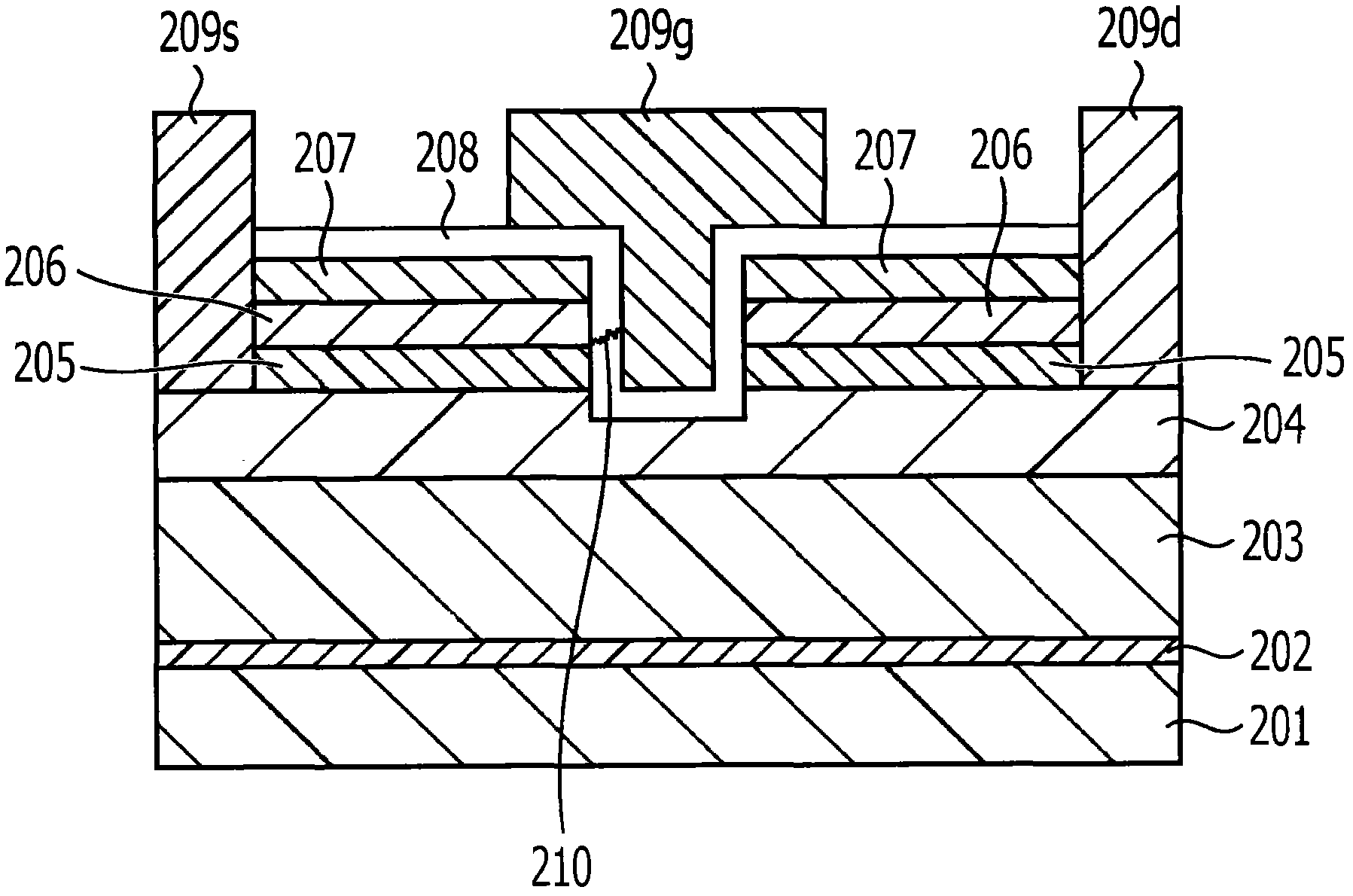

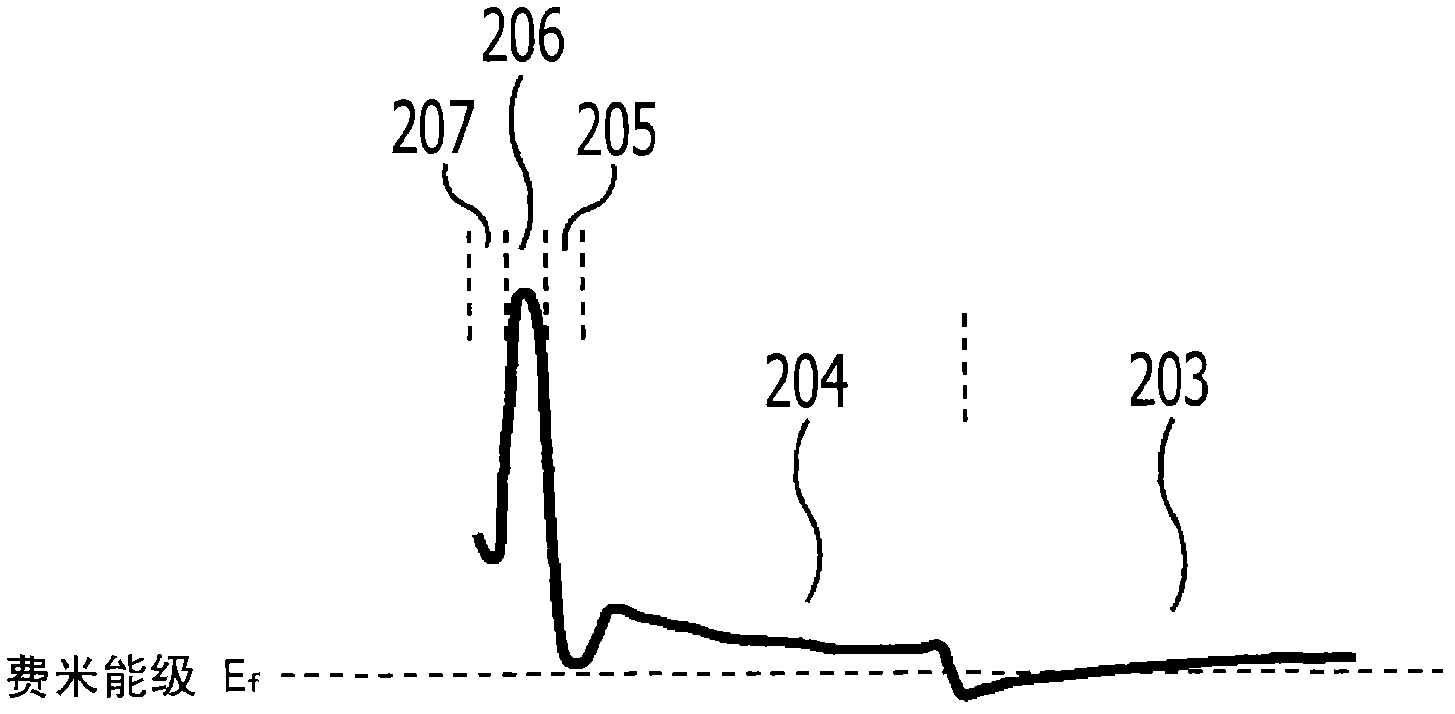

[0023] as previously stated and in Figure 1A The GaN-based HEMTs shown in often have gate leakage or reduced withstand voltage. In addition, current collapse often occurs. The inventors of the present invention have studied the cause Figure 1A The cause of gate leakage current or reduced withstand voltage in GaN-based HEMTs was shown, and the following findings were made. In GaN-based HEMTs, Figure 1B The conduction band shown is very close to the Fermi level near the interface between the i-AlN layer 206 and the n-GaN layer 205 . When a positive gate voltage is applied and the band moves down, a two-dimensional electron gas forms near this interface. Thus, if Figure 1A shown in Al 2 o 3 Dielectric breakdown 210 occurs in layer 208, resulting in gate leakage current or reduced withstand voltage.

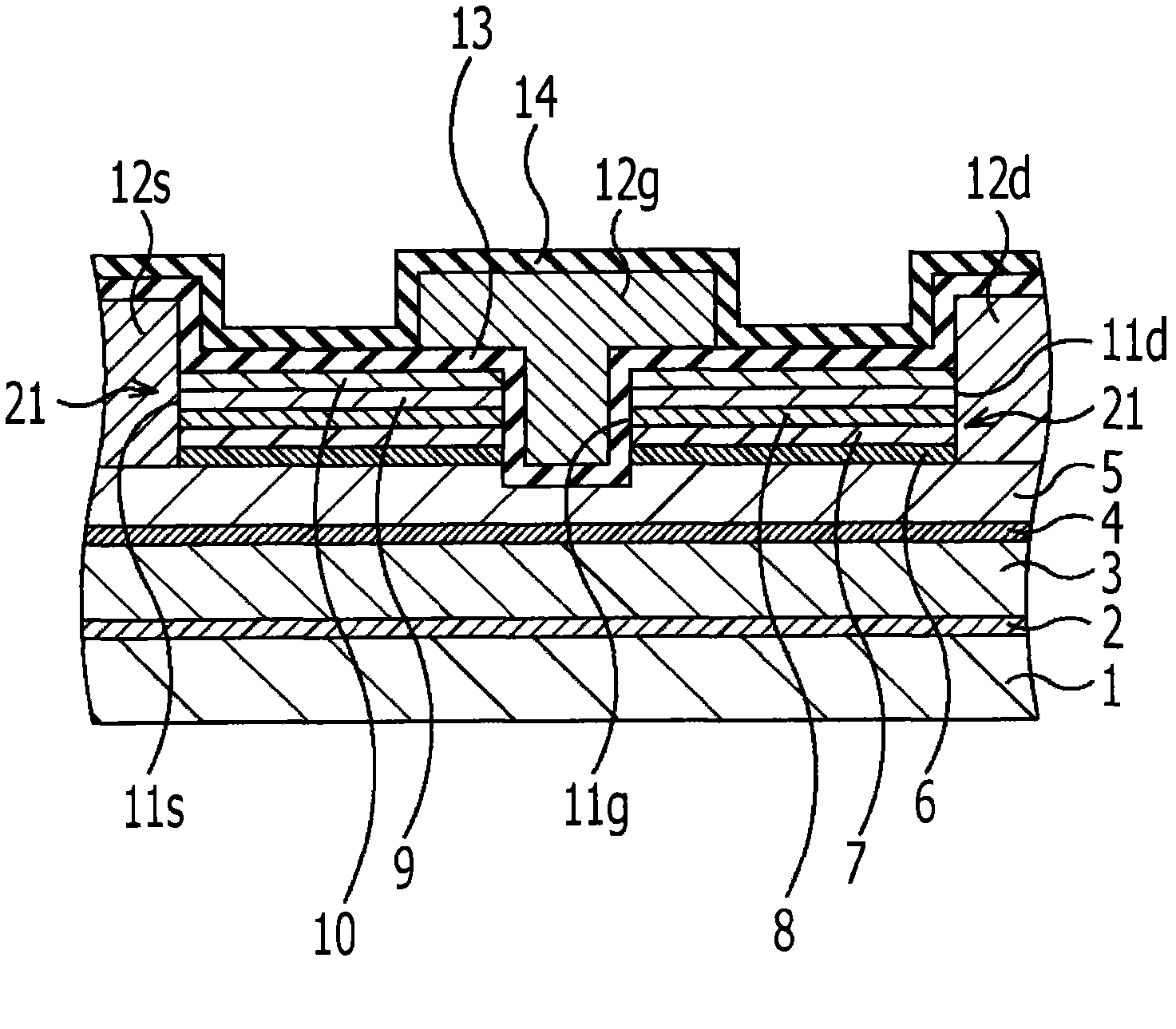

[0024] The inventors of the present invention have also studied the cause Figure 1A The cause of current collapse in the GaN-based HEMT shown, and the following findings we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com