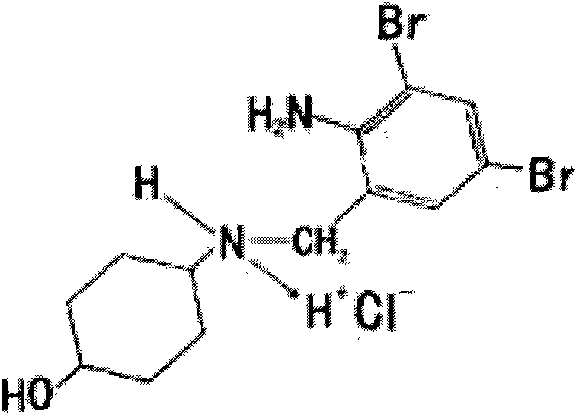

Preparing method for ambroxol hydrochloride injection

A technology of ambroxol hydrochloride and injection, applied in the field of medicine, can solve the problems of complicated preparation process, undisclosed specific prescription of ambroxol hydrochloride injection, unfavorable for commercial production, etc., and achieves simple production process and stable product quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

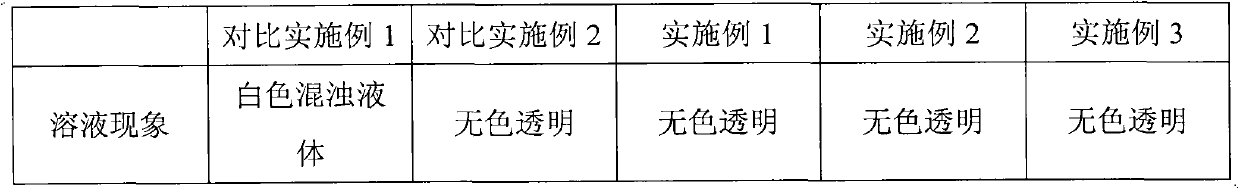

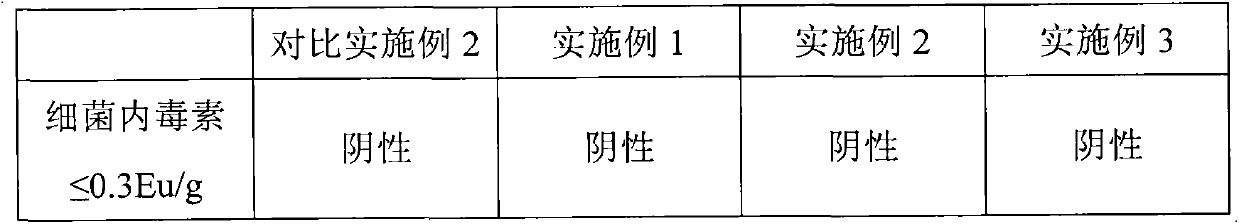

Embodiment 1

[0032] Element

[0033] The preparation method is: take about 1200g of water for injection below 30°C, add the prescribed amount of disodium hydrogen phosphate and citric acid, and dissolve completely; add the prescribed amount of ambroxol hydrochloride into the above solution, stir to dissolve, and add Water for injection to 2000ml; filtered through a 0.22 μm improved PVDF membrane, filled with nitrogen gas, sterilized at 121°C for 15 minutes to obtain ambroxol hydrochloride injection containing 7.5mg of ambroxol hydrochloride per 1ml.

Embodiment 2

[0035] Element

[0036] The preparation method is: take about 1200g of water for injection below 30°C, add the prescribed amount of disodium hydrogen phosphate and citric acid, and dissolve completely; add the prescribed amount of ambroxol hydrochloride into the above solution, stir to dissolve, and add Water for injection to 2000ml; filtered through a 0.22 μm improved PVDF membrane, filled, 121°C for 15min, to obtain ambroxol hydrochloride injection containing 7.5mg of ambroxol hydrochloride per 1ml.

Embodiment 3

[0038] Element

[0039] The preparation method is: take about 1200g of water for injection below 30°C, add the prescribed amount of disodium hydrogen phosphate and citric acid, and dissolve completely; add the prescribed amount of ambroxol hydrochloride into the above solution, stir to dissolve, and add Water for injection to 2000ml; filtered through a 0.22 μm improved PVDF membrane, filled with nitrogen gas, sterilized at 121°C for 15 minutes to obtain ambroxol hydrochloride injection containing 7.5mg of ambroxol hydrochloride per 1ml.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com