A double-layer flash tank

A flash tank, double-layer technology, applied in the field of double-layer flash tanks, can solve the problems of the distance between the liquid level sensor and the controller, increase the cost of the control system, inconvenient operation and observation, etc. Good effect and quick response effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

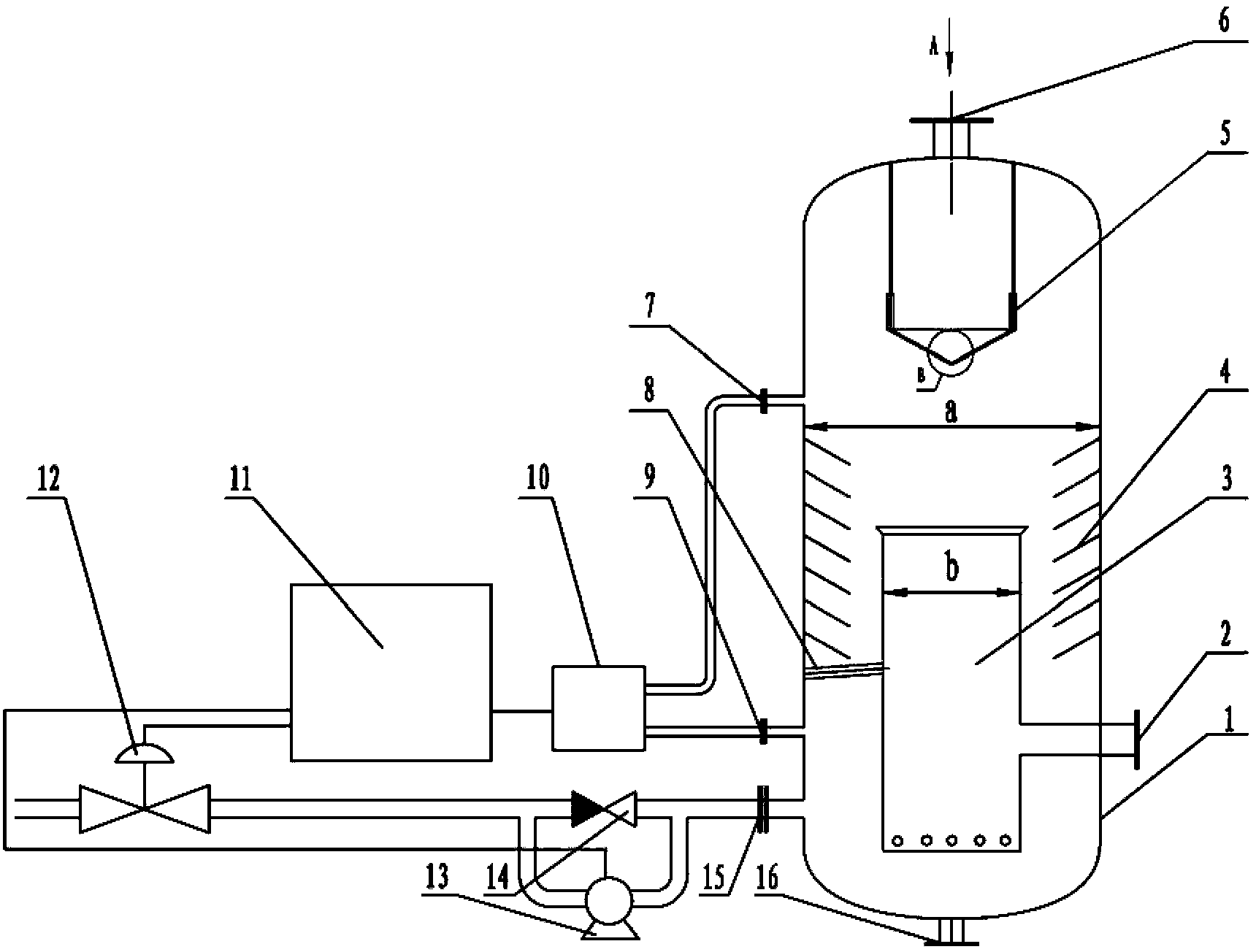

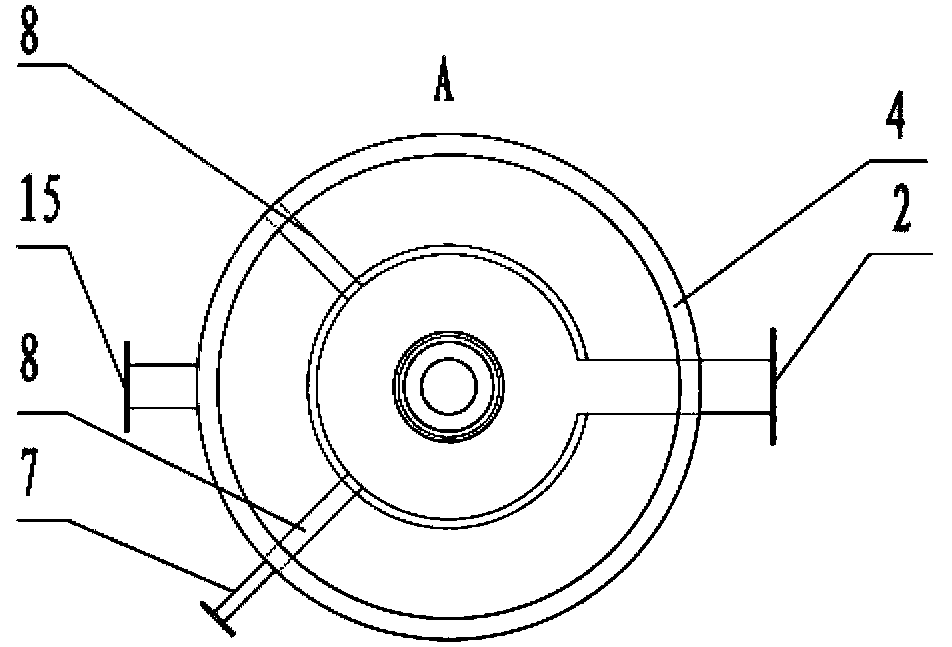

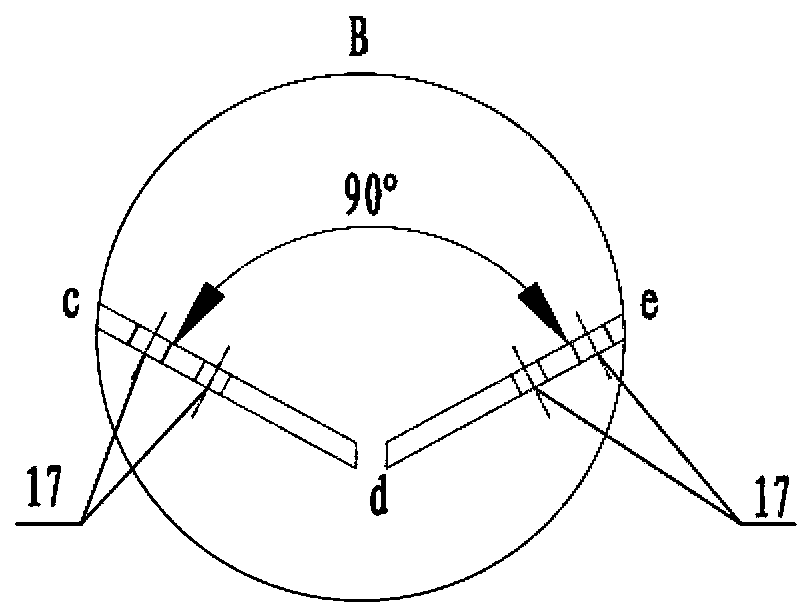

[0046] The invention relates to a high-efficiency flash tank with an automatic liquid level control device. It adopts an inner and outer two-layer nested structure. The tank has the functions of high-efficiency flash evaporation and steam-water separation. The outside of the tank leads the pressure of the high pressure side and the low pressure side to the liquid level transmitter through the pressure pipe, and the processed liquid level signal is automatically controlled by the liquid level controller, and the output signal controls the opening of the liquid level regulating valve and the water pump. start and stop, so as to achieve the purpose of automatic liquid level control. The liquid level controller includes A / D converter, single-chip liquid level control chip, LCD display, parameter adjustment buttons, optocoupler isolation relay, etc. The input signal is processed by the program and then output. The important parameters in the process will be displayed on the displa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com