Aluminum oxide encrustation block crushing production line device with multiple end product particle sizes

A kind of alumina and crust block technology, which is applied in the field of alumina crust block crushing production line equipment, can solve problems such as adhesion, passing through a sieve before, and affecting the transportation of ground materials, so as to achieve the effect of dust collection and improve work Environment, the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

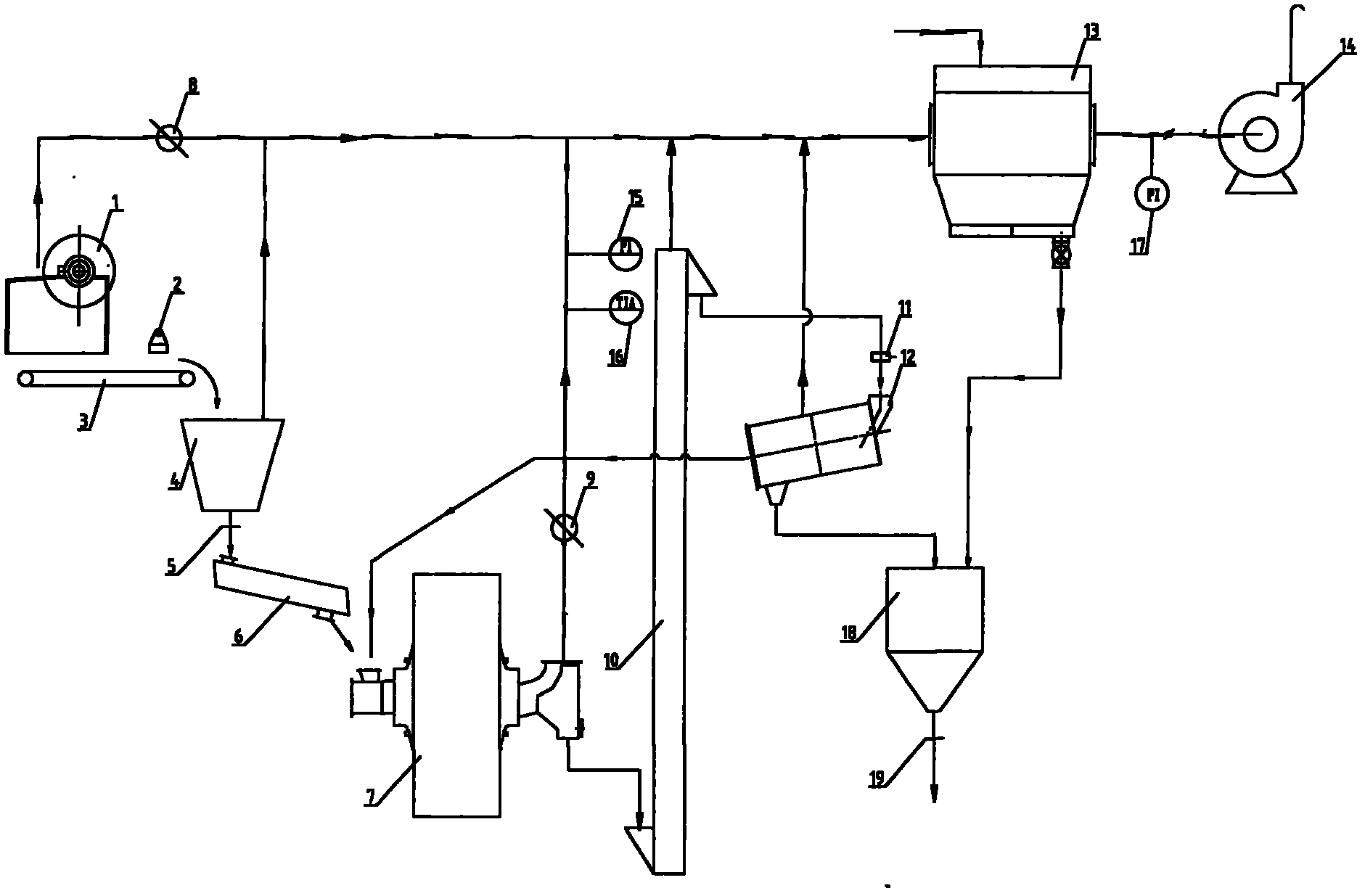

[0034] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the following will be combined with the accompanying drawings and preferred embodiments to describe a production line device for crushing alumina crust blocks with various particle sizes of finished products according to the present invention. Its specific implementation, structure, feature and effect thereof are described in detail as follows.

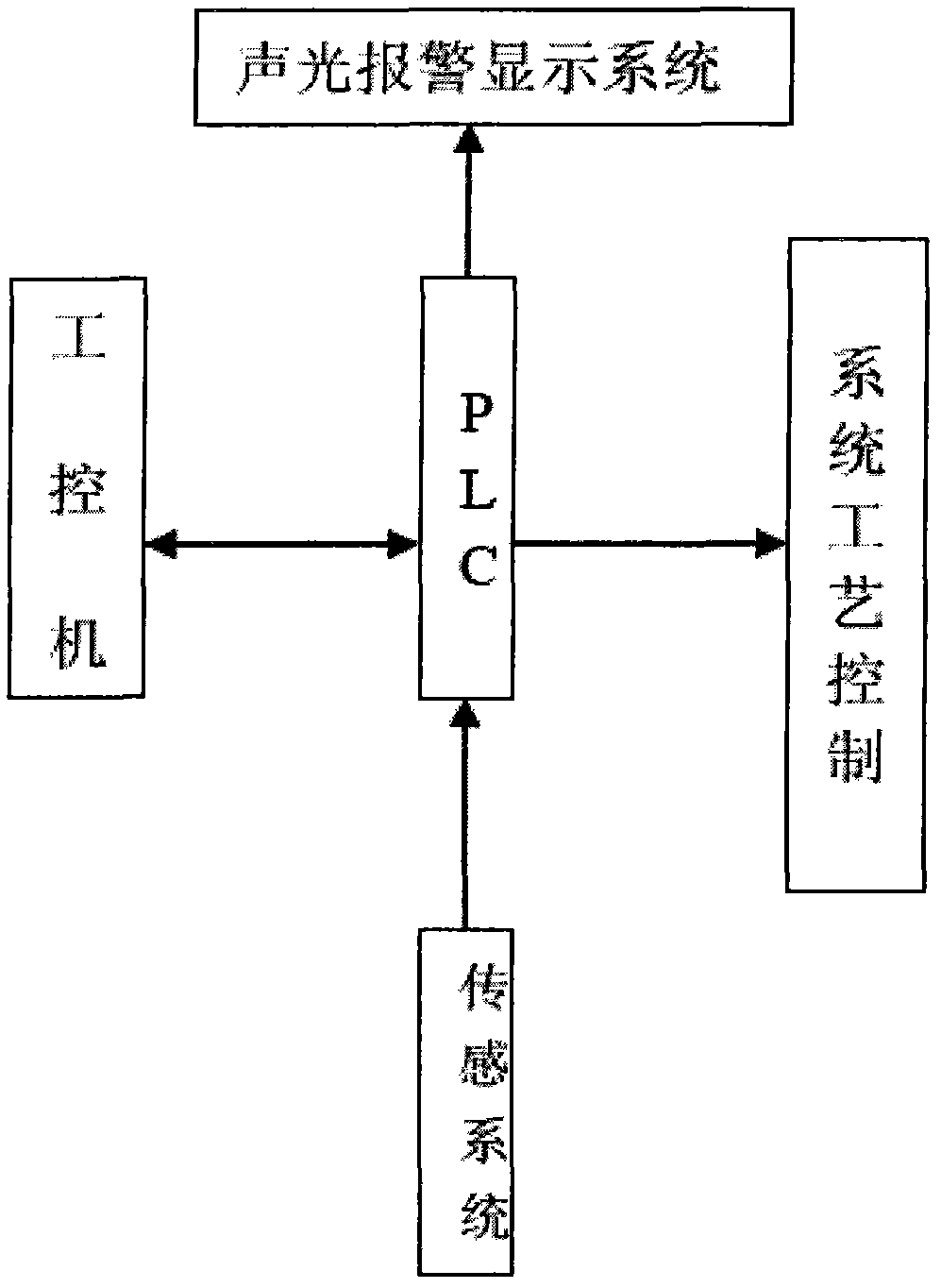

[0035] The present invention is a production line device for crushing alumina crust blocks with various particle sizes. Electric butterfly valve, second electric butterfly valve, bucket elevator, second iron remover, cylindrical screen, bag filter, exhaust fan, first pressure transmitter, temperature transmitter, second pressure transmitter, finished product warehouse , constitutes a flapper valve.

[0036] A conveyor is installed under the crusher, a dust collector is installed at the inlet en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com