Straw briquetting forming machine provided with double layers of circular moulds and double layers of compressing rolls

A forming machine and double-layer technology, which is applied in the direction of material forming presses, presses, manufacturing tools, etc., can solve the problems of low output, large floor space, and large volume in the production of briquettes, and achieve high production efficiency and occupation The effect of small floor area and improvement of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The following uses embodiments to further illustrate the technical solution of the present invention, which will help to further understand the advantages and effects of the technical solution of the present invention.

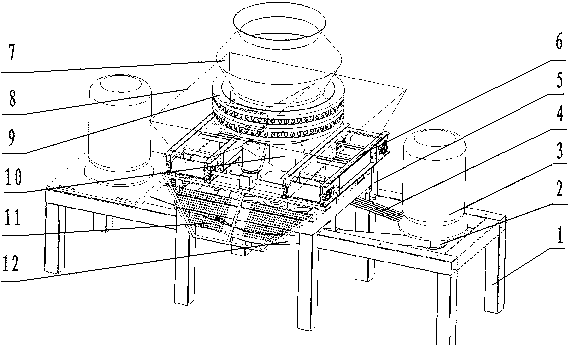

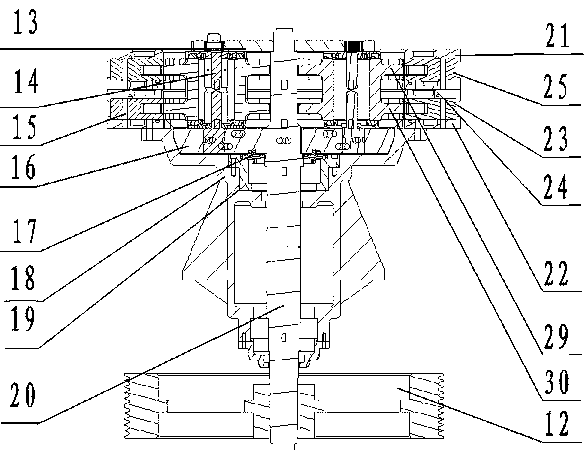

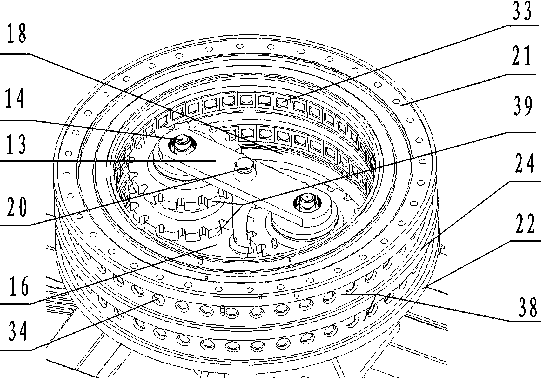

[0037] From 1 picture to Figure 8 It can be seen that the present invention provides a double-layer ring mold double-layer pressing roller straw briquetting machine. The prior art part includes a frame 1, a large motor 3, a belt 4, a small pulley 2, a large pulley 12, a main shaft 20, and a screen 11. , Discharge hopper 8, bracket 5, feed hopper 7, conveying mechanism 6 and compression chamber 9; the compression chamber consists of the bottom cavity of the compression chamber 18, the grinding disc 16, the double-layer pressure roller 39, the double-layer ring die 38 and the hopper 7 Composition; the double-layer ring die 38 from bottom to top is composed of the lower plate 22, the lower ring die layer 23, the supporting platen 24, the upper ring die layer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com