Titanium tetrachloride copper wire tower with self-cleaning function and copper wire ball cleaning method thereof

A technology of titanium tetrachloride and copper wire, which is applied to chemical instruments and methods, cleaning methods and utensils, cleaning methods using liquids, etc., can solve problems such as high labor intensity, poor production conditions, and copper-containing wastewater, and achieve good results. Social and economic benefits, reduced maintenance costs, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

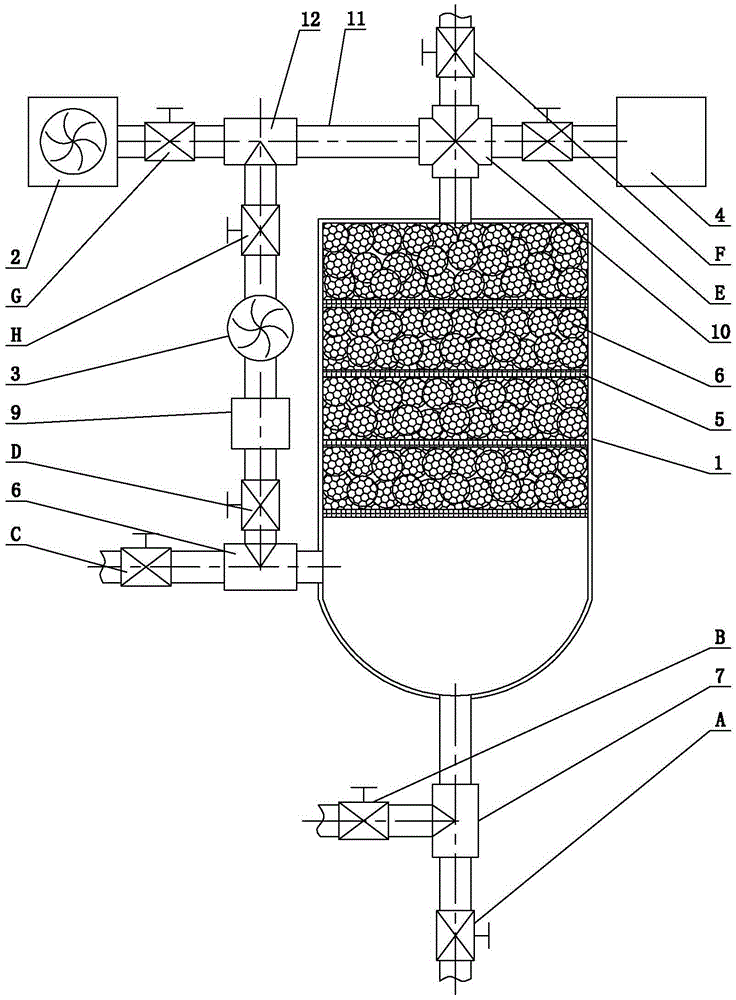

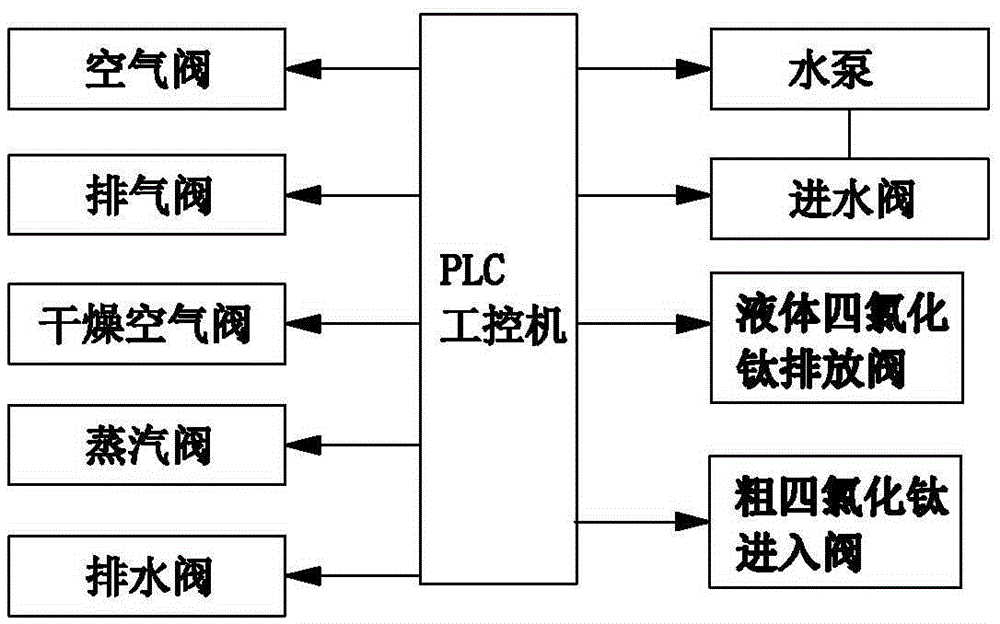

[0020] Embodiment 1: The titanium tetrachloride copper wire tower with self-cleaning function and its copper wire ball cleaning method are to open the drain valve B first, and close all other valves; Clean the plate 5 and the copper wire ball 6 for about 10 minutes, close the water inlet valve G after the water discharged from the drain valve B is clear; open the steam valve C, and let in steam at 80°C for 15 minutes; then open the water inlet valve G and the air Valve H passes water and high-pressure air to the inside of the tower body 1 for about 10 minutes, prompting the copper wire ball 6 to vibrate, and intermittently switches the water inlet valve G, so that the pH value of the water flowing out of the drain valve B is 6, that is, the copper wire ball 6 is completed. Cleaning of silk ball 6. Then close the drain valve B, steam valve C, water inlet valve G, and air valve H, open the dry air valve D and the exhaust valve, and pass in dry air at 120°C for 4 hours, and the d...

Embodiment 2

[0021] Embodiment 2: The titanium tetrachloride copper wire tower with self-cleaning function and its copper wire ball cleaning method are to open the drain valve B first, and close all other valves; Clean the plate 5 and the copper wire ball 6 for about 10 minutes. After the water discharged from the drain valve B is clear, close the water inlet valve G; open the steam valve C, and let in steam at 90°C for 12.5 minutes; then open the water inlet valve G and air Valve H passes water and high-pressure air to the inside of the tower body 1 for about 10 minutes, prompting the copper wire ball 6 to vibrate, and intermittently switches the water inlet valve G, so that the pH value of the water flowing out of the drain valve B is 6.5, that is, the copper wire ball 6 is completed. Cleaning of silk ball 6. Then close the drain valve B, steam valve C, water inlet valve G, and air valve H, open the air heating dryer 9, dry air valve D and exhaust valve, feed in dry air at 135°C for 4 ho...

Embodiment 3

[0022] Embodiment 3: this titanium tetrachloride copper wire tower with self-cleaning function and its copper wire ball cleaning method are to open drain valve B earlier, close all other valves; Clean the plate 5 and the copper wire ball 6 for about 10 minutes. After the water discharged from the drain valve B is clear, close the water inlet valve G; open the steam valve C, and let in steam at 100°C for 10 minutes; then open the water inlet valve G and air Valve H passes water and high-pressure air to the inside of the tower body 1 for about 10 minutes, prompting the copper wire ball 6 to vibrate, and intermittently switches the water inlet valve G, so that the pH value of the water flowing out of the drain valve B is 7, that is, the copper wire ball 6 is completed. Cleaning of silk ball 6. Then close the drain valve B, steam valve C, water inlet valve G, and air valve H, open the dry air valve D and the exhaust valve, and pass in dry air at 150°C for 4 hours, and the drying o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com