Fake metal plastic cement material preparation method

A plastic material and metal-imitation technology, which is applied in the field of preparation of metal-imitation plastic materials, can solve problems such as not easy to remove and affect product appearance, and achieve the effects of less environmental pollution, easy recycling, and beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

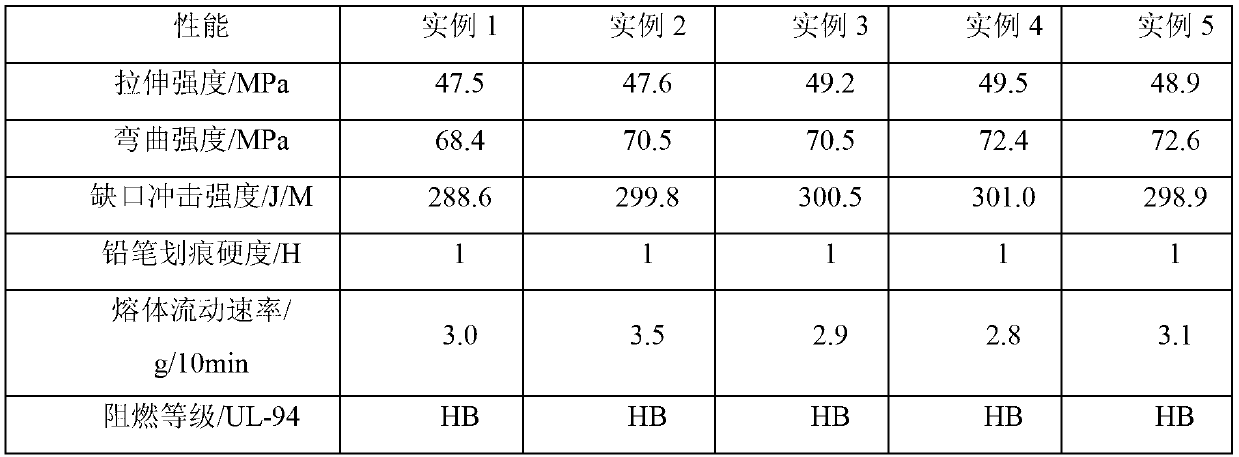

Examples

preparation example Construction

[0029] The invention discloses a method for preparing a metal-like plastic material, which comprises the following steps:

[0030] Step 1. Surface-treat the 300-500 mesh metal powder first, then immerse the metal powder in the coupling agent solution at room temperature for 0.5-2h, then filter the coupling agent solution in the metal powder, and Dry at ℃ to constant weight for later use;

[0031] Step 2. Premix 5-50 parts of the metal powder obtained in step 1, 1-5 parts of lubricant, 5-30 parts of anti-impact additive and 100 parts of resin in a high-speed mixer, and then place the premixed product in a twin-screw Granulate at 220-280° C. in a granulator to obtain the metal-like plastic material.

Embodiment 1

[0032] Example 1 is a control experiment in which the metal powder is not subjected to surface treatment.

[0033] Step 1. Submerge 300-500 mesh iron powder metal powder in 0.1% β-(3,4-epoxycyclohexyl)ethyltrimethoxysilane coupling agent aqueous solution at room temperature for 0.5h, then The β-(3,4-epoxycyclohexyl)ethyltrimethoxysilane aqueous solution in the iron powder metal powder is filtered by a centrifuge, and dried at 150°C to constant weight for use;

[0034] Step 2, 25 parts of iron powder metal powder that step 1 obtains, 3 parts of white oil lubricants, 20 parts of methyl methacrylate-butadiene-styrene graft copolymer anti-impact additives and 100 parts of mixed resins ( 50 parts each of ABS resin and PC resin) were premixed in a high mixer, and then the premix was placed in a parallel twin-screw reverse granulator and granulated at 250°C to obtain the metal-like plastic material.

Embodiment 2

[0036] Step 1. First, the 300-500 mesh iron powder metal powder is surface-treated by phosphating surface treatment method. After the surface treatment of the iron powder metal powder is completed, the iron powder metal powder is then immersed in 0.1% gamma at room temperature -(2,3 glycidoxy) propyl trimethoxy silane coupling agent ethanol solution for 2h, then the γ-(2,3 glycidoxy) propyl trimethoxy in the iron powder metal powder The silane-ethanol solution was filtered by a centrifuge and dried to constant weight at 50°C for later use;

[0037] Step 2, 25 parts of iron powder metal powder that step 1 obtains, 3 parts of white oil lubricants, 20 parts of methyl methacrylate-butadiene-styrene graft copolymer anti-impact additives and 100 parts of mixed resins ( 50 parts each of ABS resin and PC resin) were premixed in a high mixer, and then the premix was placed in a parallel twin-screw reverse granulator and granulated at 250°C to obtain the metal-like plastic material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com