Biomass furnace with tertiary combustion structure

A biomass stove and secondary combustion-supporting air technology, which is used in household cooking utensils, household stoves/stoves, solid heating fuels, etc., can solve the problems of insufficient combustion and environmental pollution, and achieve the elimination of black smoke, environmental protection and fuel saving. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in further detail below in conjunction with the accompanying drawings.

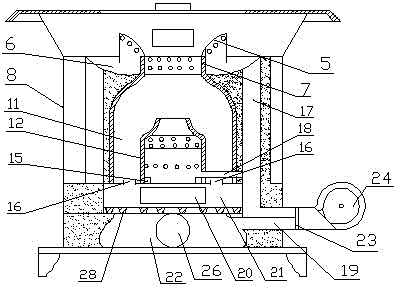

[0012] refer to figure 1 , a biomass furnace with a three-time combustion-supporting structure, including a furnace body 8 and a furnace 11 in the furnace body, the lower part of the furnace 11 is used as a combustion chamber 21, and a feed port is opened on the outer wall of the furnace at the corresponding position of the combustion chamber 21 20. A furnace tooth 28 is installed at the lower end of the combustion chamber 21, and below the furnace tooth 28 is an ash hopper 22, and an air inlet 26 is opened on the outer wall of the ash hopper 22; a secondary Combustion-supporting liner 12, the setting of the secondary combustion-supporting liner 12 enables the center of the furnace to receive more air volume to achieve full combustion in all directions; the interface between the secondary combustion-supporting liner 12 and the combustion chamber 21 A py...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com