Heating furnace brick holding frame structure

A heating furnace and frame structure technology, applied in the field of supporting bricks, can solve the problems of difficulty in adjusting the levelness of the supporting bricks, easy deformation, poor quality of the production of the supporting bricks, welding quality of angle steel, etc. , the effect of saving nickel resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solution will be further described below in conjunction with the accompanying drawings and embodiments.

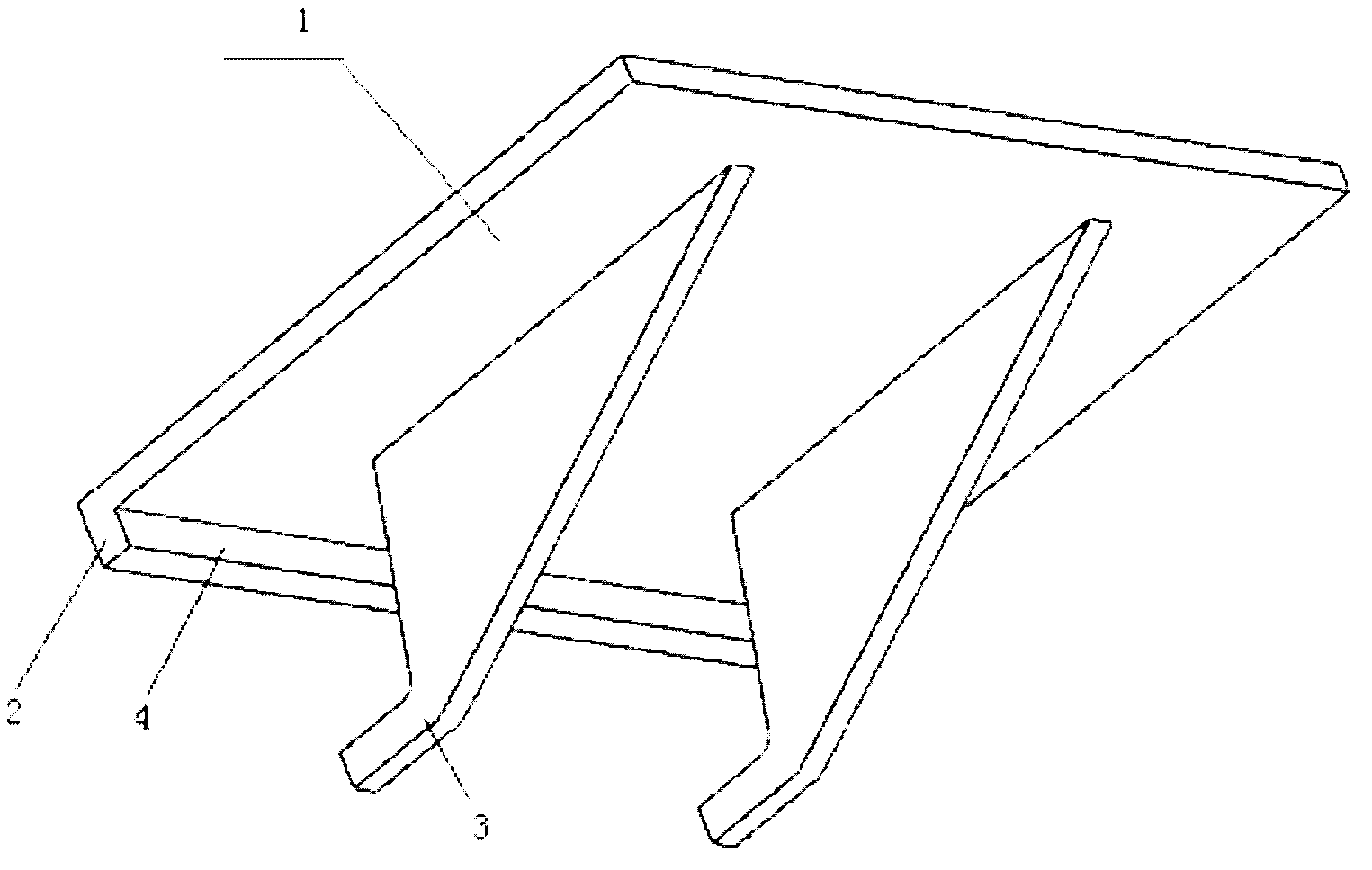

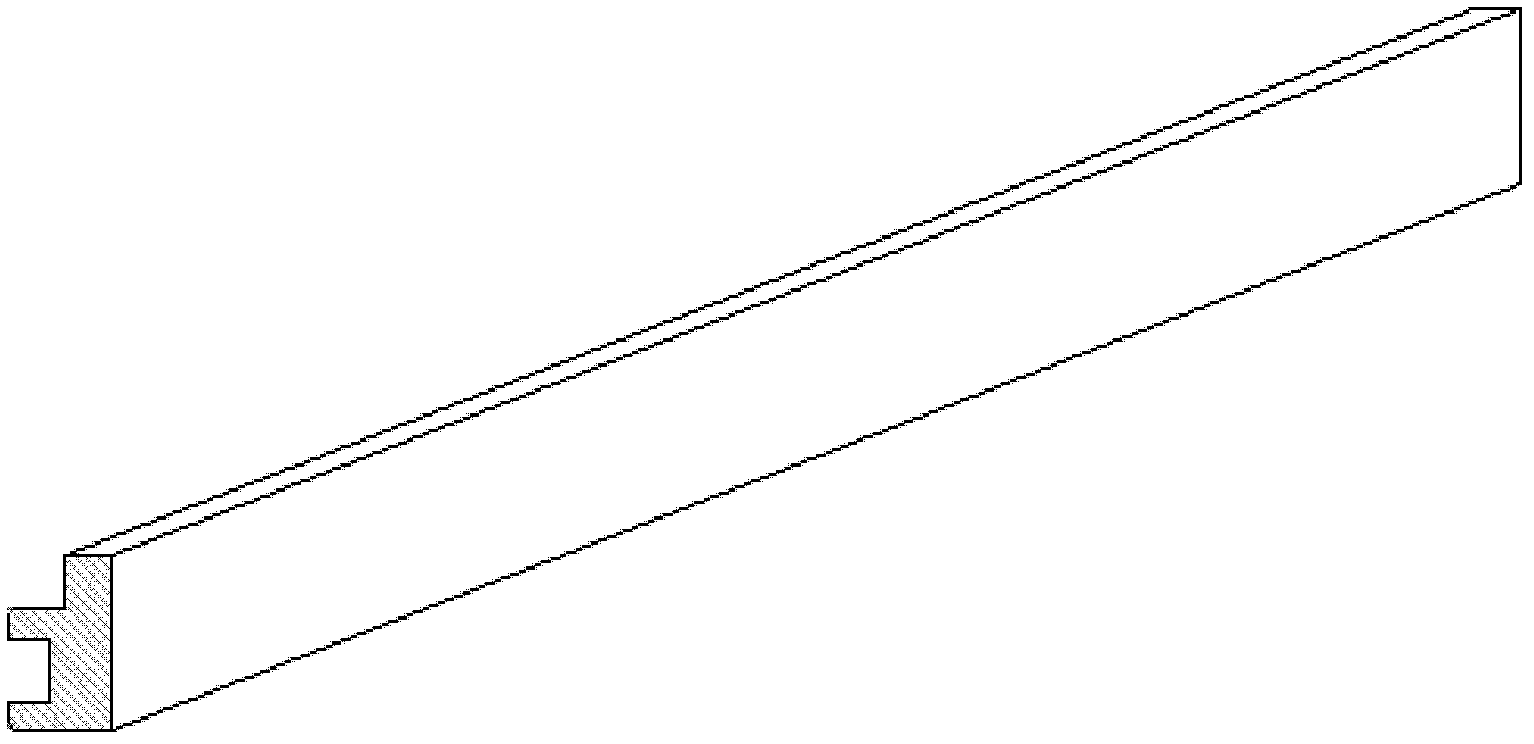

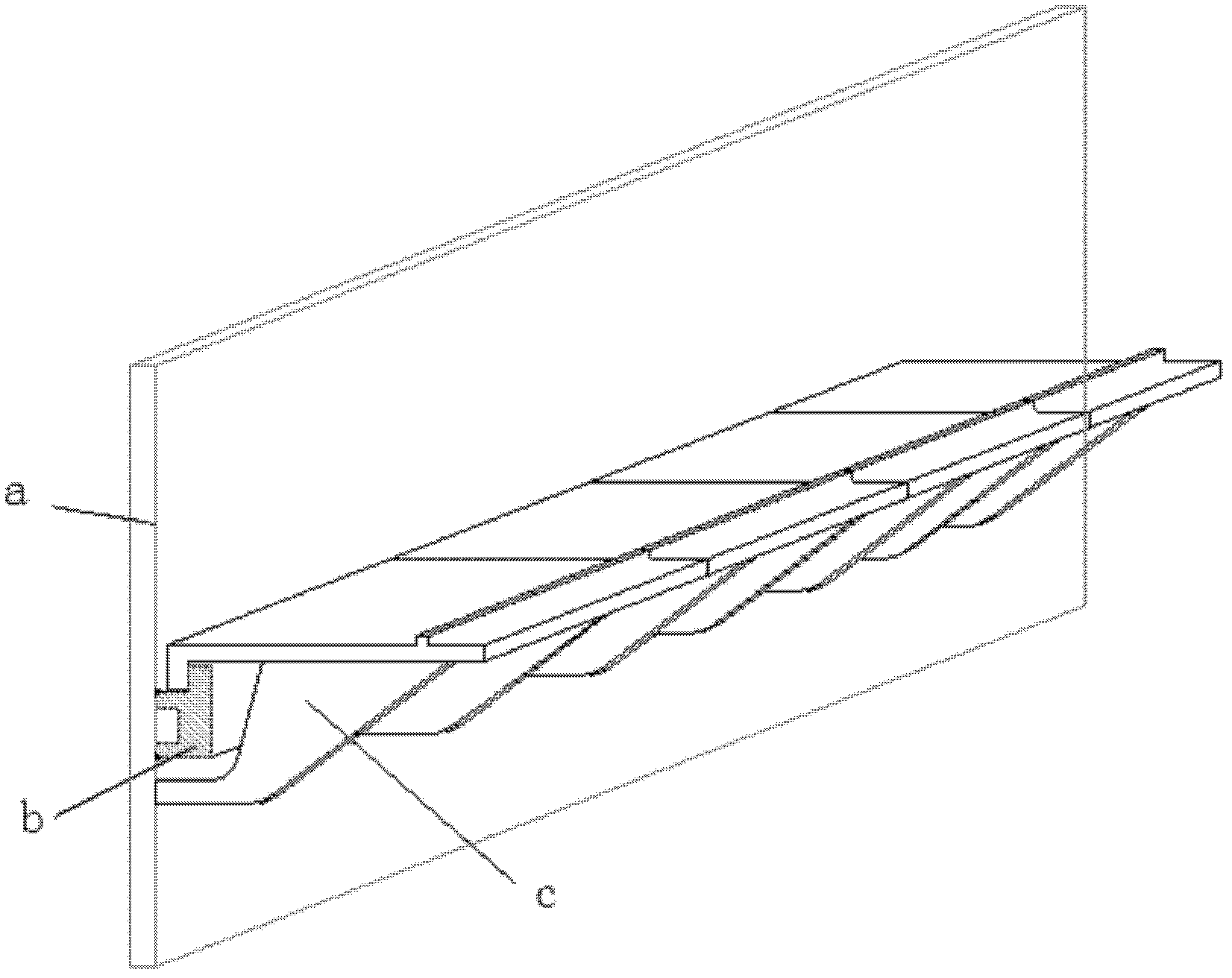

[0028] A brick support structure for a heating furnace, including a brick support plate, a brick puller and a heating furnace wall; the brick puller is a strip structure, the cross section of the strip structure is F-shaped, and two parallel bars of the F-type The shorter side is connected to the wall plate of the heating furnace; the brick supporting board includes a board body and a bracket; one edge of the board body is provided with a bend towards the back side of the board body, and the bracket is connected to the back side of the board body; the bracket It is L-shaped, one side of the L-shaped bracket is connected to the board; the bend of the board is buckled on the longer side of the F-shaped; the other side of the L-shaped bracket points to the bend and is against the heating furnace Siding.

[0029] The bending is perpendicular to the plane ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com