Control system for printed circuit board (PCB) rotating machine

A PCB board and control system technology, applied in the field of PCB board rotary machine control system, can solve the problems of high cost, low control precision, poor stability, etc., and achieve the effect of convenient realization, high degree of automation and stable control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

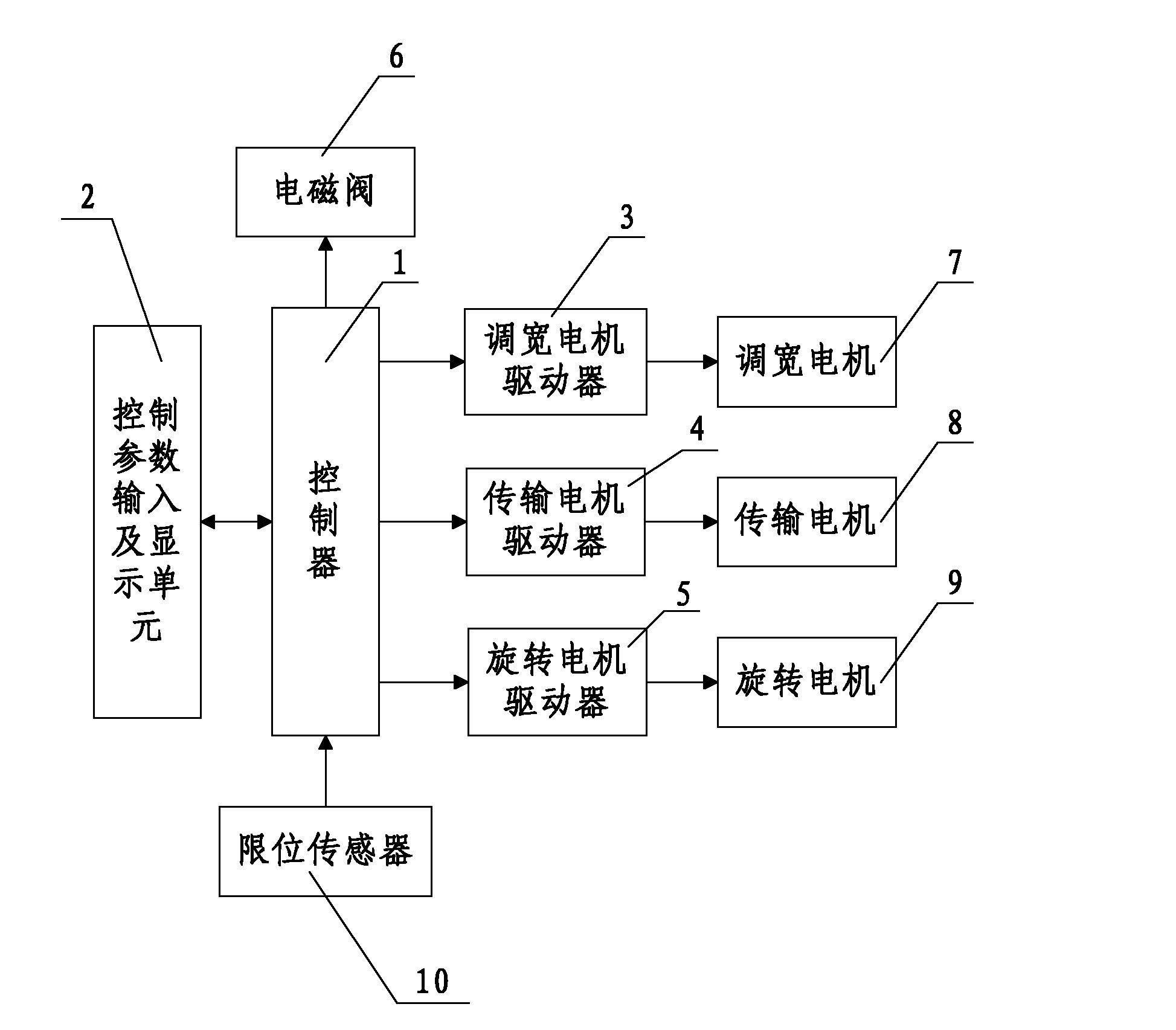

[0024] like figure 1 As shown, the present invention includes a controller 1 and a control parameter input and display unit 2 connected with the controller 1 and used for inputting and displaying control parameters, the output of the controller 1 is connected with a width-adjusting motor driver 3, The transmission motor driver 4, the rotating motor driver 5 and the solenoid valve 6 used to control the reciprocating motion of the cylinder driving the movement of the limit device, the output end of the width adjustment motor driver 3 is used to drive the width adjustment device to adjust the width of the PCB board transmission device The width adjustment motor 7 is connected, the output end of the transmission motor driver 4 is connected with the transmission motor 8 for driving the PCB transmission device and the PCB board is transmitted to the limit device, the output end of the rotation motor driver 5 It is connected with the rotating motor 9 for driving the rotating device t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com