Transformer electric conduction structure and transformer

A conductive structure and transformer technology, applied in the direction of transformer/inductor coil/winding/connection, transformer/inductor parts, circuits, etc., can solve the problem of not effectively reducing the output path of the transformer, reducing the volume of the loss transformer device, Affect circuit reliability and efficiency and other issues, to achieve the effect of improving space utilization, improving power density and efficiency, and reducing volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

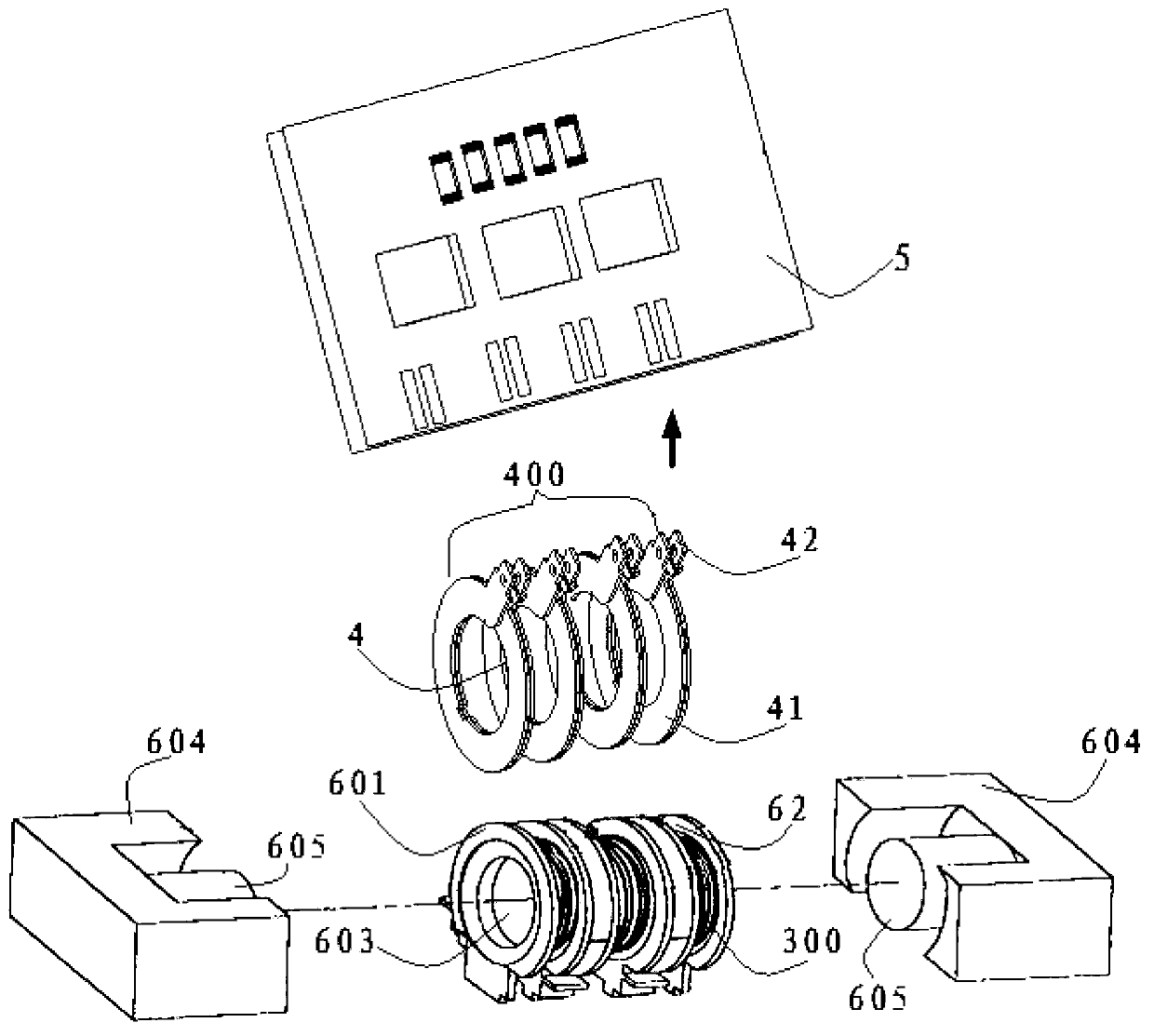

[0135] Such as Figure 7 As shown, the transformer of this embodiment is used to connect with the printed circuit board 5; it includes a primary winding 300, a plurality of conductive sheets 4 and a pair of magnetic core groups 604;

[0136] As an embodiment, the transformer of the present invention also includes a plurality of winding racks 6; the winding racks 6 are ring-shaped;

[0137] The magnetic core group 604 is provided with a protruding end 605. It should be noted that in this embodiment, the magnetic core group 604 is selected as a PQ type, but as an alternative to other embodiments of the present invention, the transformer adopts The magnetic core group can also choose other types;

[0138] The reel frame 6 is sleeved on the protruding end 605 of the magnetic core set 604;

[0139] The winding frame 6 is provided with a winding groove 62; the primary winding 300 is wound in the winding groove 62; the winding frame 6 wound with the primary winding 300 is set in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com