Recovery method of gyrocompass automatic navigation (GaN)-based epitaxial wafer substrate

A recycling method and technology of epitaxial wafers, which are applied in the fields of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problem that wet etching is difficult to obtain high corrosion rate, it is difficult to increase the production capacity of recycled substrates, and the substrate of epitaxial wafers Damage and other problems, to achieve the effect of increasing speed, maintaining integrity, and process control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

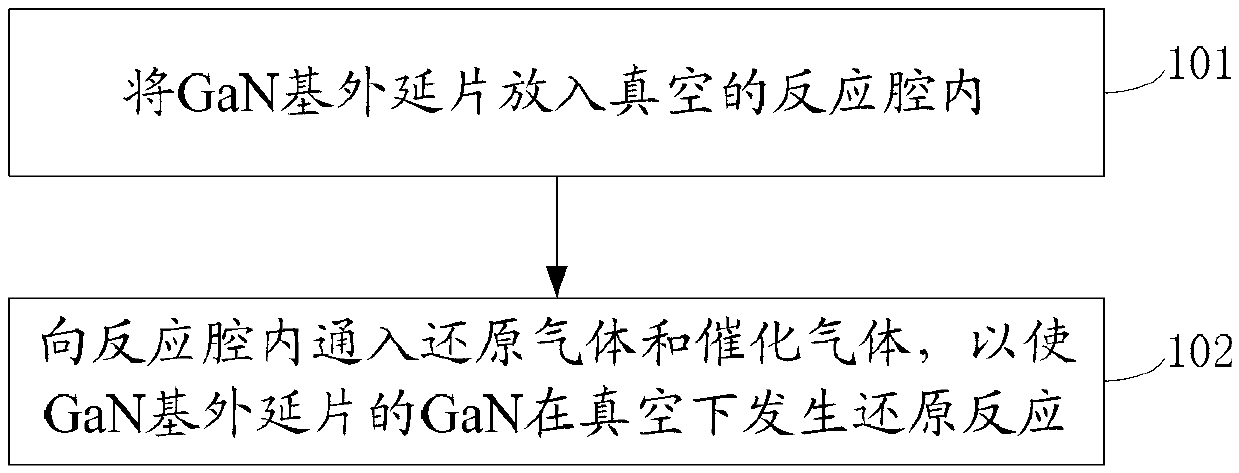

[0023] The embodiment of the present invention provides a method for recovering GaN-based epitaxial wafer substrates, see figure 1 , the method includes:

[0024] Step 101: Put the GaN-based epitaxial wafer into a vacuum reaction chamber.

[0025] Specifically, a GaN-based epitaxial wafer generally includes a substrate, and an n-type GaN layer, a multi-quantum well layer and a p-type GaN layer sequentially stacked on the substrate.

[0026] Specifically, the substrate may be an aluminum oxide substrate or a silicon carbide substrate.

[0027] Step 102: Feed reducing gas and catalytic gas into the reaction chamber, so that the GaN on the GaN-based epitaxial wafer undergoes a reduction reaction under vacuum.

[0028] Specifically, in this embodiment, the reducing gas may be hydrogen.

[0029] Specifically, in this embodiment, the catalytic gas may be hydrogen chloride gas.

[0030] Specifically, the reaction temperature of the reduction reaction is 900°C to 1100°C.

[0031]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com