Covering film of flexible printing circuit board and flexible printing circuit board structure and manufacturing method thereof

A flexible printed circuit, flexible printing technology, applied in the direction of printed circuit parts, printed circuit secondary treatment, chemical instruments and methods, etc., can solve problems such as poor flexibility, explosive boards, thick protective films, etc. problems, to achieve the effect of good flexibility, simple manufacturing process, and good softness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1: This embodiment discloses a cover film of a flexible printed circuit board, a structure of a flexible printed circuit board having the cover film, and forming the cover film on the substrate to make the flexible printed circuit board of this embodiment. How printed circuit boards work.

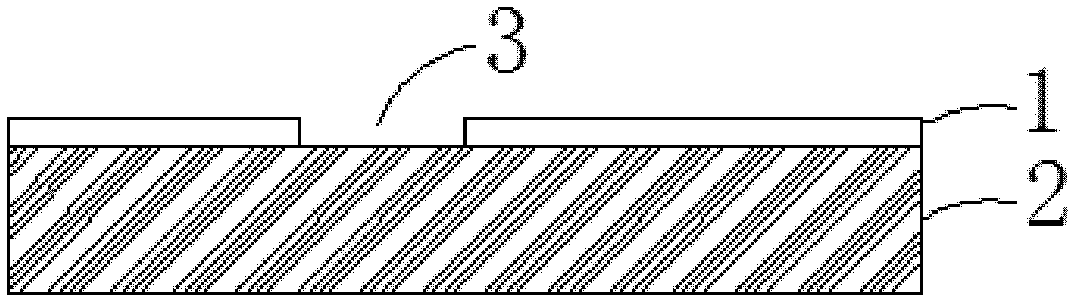

[0034] The flexible printed circuit board structure of this embodiment, such as figure 1 As shown, it is composed of a formed circuit substrate 2 and a cover film 1 of this embodiment. The cover film of this embodiment is a liquid-baked polyamide-imide film 1, and the liquid-baked polyamide-imide film 1 It is formed by printing the precursor composition solution of polyamideimide on the part to be covered on the surface of the formed circuit substrate 2 and then baking it. This is the cover film of the embodiment (liquid baking type polyamideimide The film 1) has a thickness of 5 μm to 25 μm, and a window opening 3 is formed at a position not covered with the liquid bakin...

Embodiment 2

[0044] Embodiment 2: This embodiment discloses a cover film of a flexible printed circuit board, a structure of a flexible printed circuit board having the cover film, and forming the cover film on the substrate to make the flexible printed circuit board of this embodiment. How printed circuit boards work.

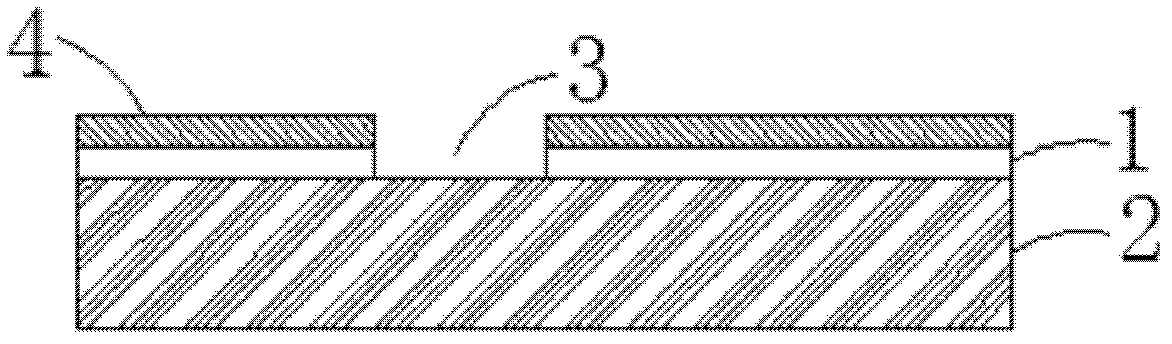

[0045] The flexible printed circuit board structure of this embodiment, such as figure 2 As shown, it is composed of a formed circuit substrate 2 and a cover film 1 of this embodiment. The cover film of this embodiment is composed of a liquid baking type polyamide-imide film 1 and a photosensitive polyimide protective film 4. Liquid baking polyamide-imide film 1 is formed by printing the precursor composition solution of polyamide-imide on the part to be covered on the surface of the formed circuit substrate 2 and then baking. The liquid baking polyamide The imide film 1 has a thickness of 5 μm to 25 μm, and a window opening 3 is formed at a position not covered with the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com