Lithium-ion secondary battery

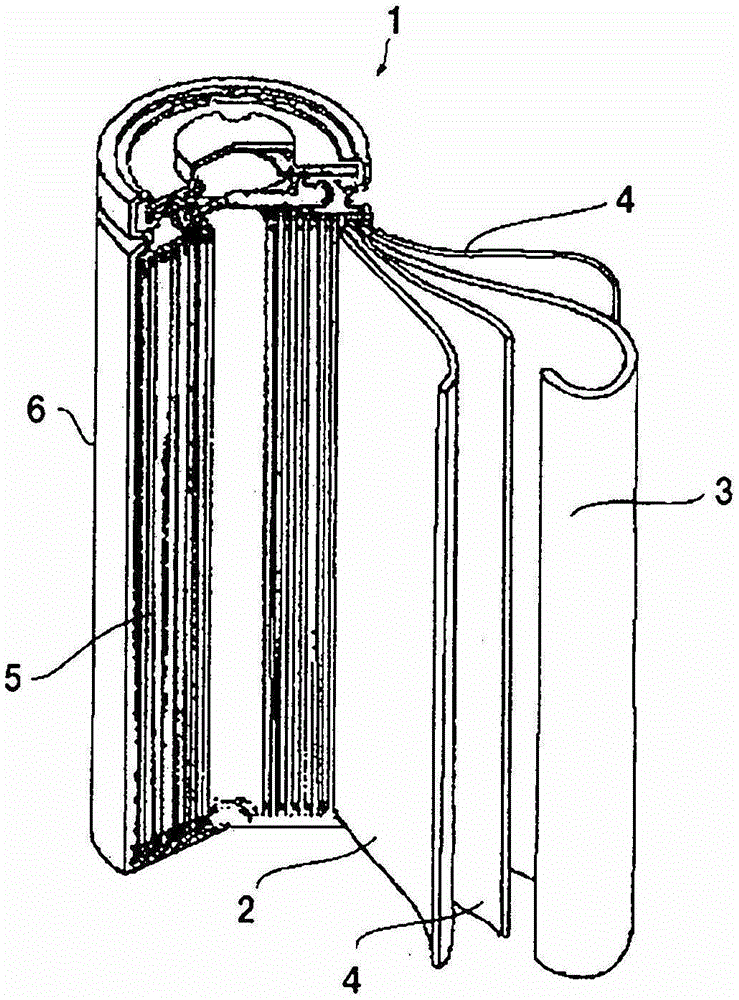

一种二次电池、锂离子的技术,应用在二次电池、锂蓄电池、电池电极等方向,能够解决燃烧加速等问题,达到移动经路坚固、维持高率放电特性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

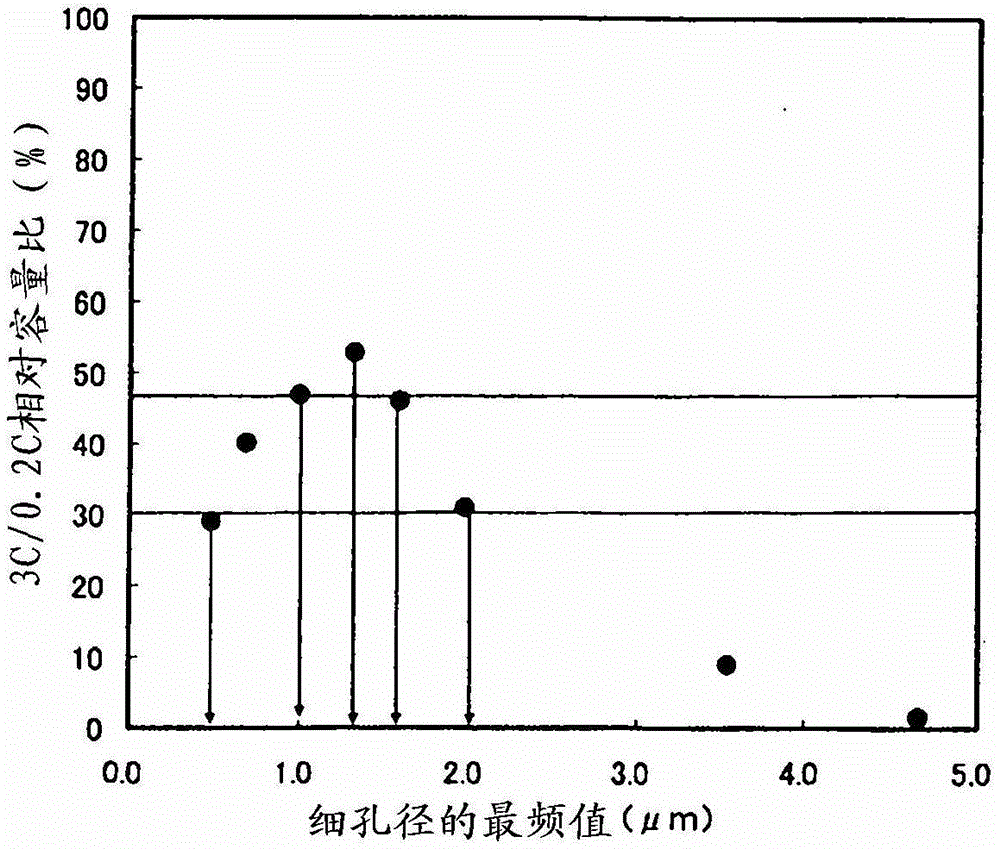

Embodiment 1

[0037] In Example 1, as shown in Table 1 below, a phosphazene compound (manufactured by Bridgestone Corporation, trade name Phoslight (registered trademark) , liquid) of 15% by volume. 4% by mass of a phosphazene compound (manufactured by Bridgestone Corporation, trade name Phoslight (registered trademark), solid state) of a flame retardant blended in the positive electrode mixture, lithium manganate powder (average secondary particle size) of the positive electrode active material diameter 25 μm), 5 mass % of flake graphite, and 7 mass % of PVDF. The mode value of the pore diameter of the positive electrode mixture was measured using a mercury porosimeter (manufactured by Shimadzu Corporation, Autopore IV9520), and a lithium ion secondary battery 1 in which the mode value of the pore diameter of the positive electrode mixture was 0.5 μm was produced. A plurality of lithium ion secondary batteries having different mode values of the pore diameters of the positive electrode ...

Embodiment 2

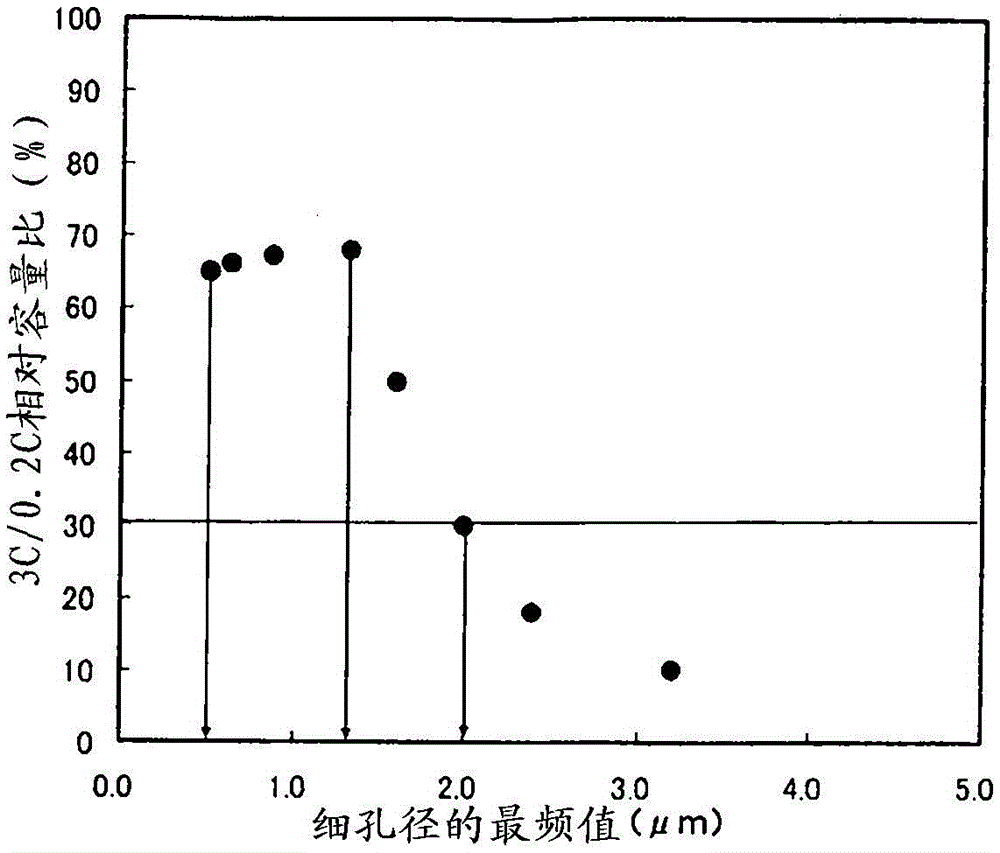

[0041] As shown in table 1, in embodiment 2, use the concentration of lithium salt to be the non-aqueous electrolytic solution of 1.5M, in addition, operate in the same way as embodiment 1, the mode value of the pore diameter of making positive electrode mixture is different multiple Li-ion secondary batteries. The mode values of the pore diameters of the positive electrode mixtures of these lithium ion secondary batteries were 0.5 μm, 0.6 μm, 0.9 μm, 1.3 μm, 1.6 μm, 2.0 μm, 2.3 μm, and 3.2 μm, respectively.

Embodiment 3

[0043] As shown in Table 1, in Example 3, a non-aqueous electrolyte solution with a lithium salt concentration of 1.5M was used, and 2% by mass of the phosphazene compound was blended in the positive electrode mixture. In addition, it was the same as in Example 1. In this operation, a plurality of lithium ion secondary batteries having different mode values of pore diameters of positive electrode mixtures were manufactured. The mode values of the pore diameters of the positive electrode mixtures of these lithium ion secondary batteries were 0.5 μm, 1.0 μm, 1.3 μm, 1.9 μm, 2.0 μm, 2.2 μm, 2.8 μm, and 3.0 μm, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| aperture size | aaaaa | aaaaa |

| aperture size | aaaaa | aaaaa |

| aperture size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com