Heavy type high-efficient composite broken line edge blade for cutting and turn milling

A technology for cutting turning and broken line blades, which is applied to milling cutters, cutting tools for lathes, turning equipment, etc. It can solve problems such as easy fracture failure, blade loss of hardness required for cutting, and reverse cutting of workpieces, so as to improve mechanical shock resistance. , reduce the depth, reduce the effect of contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

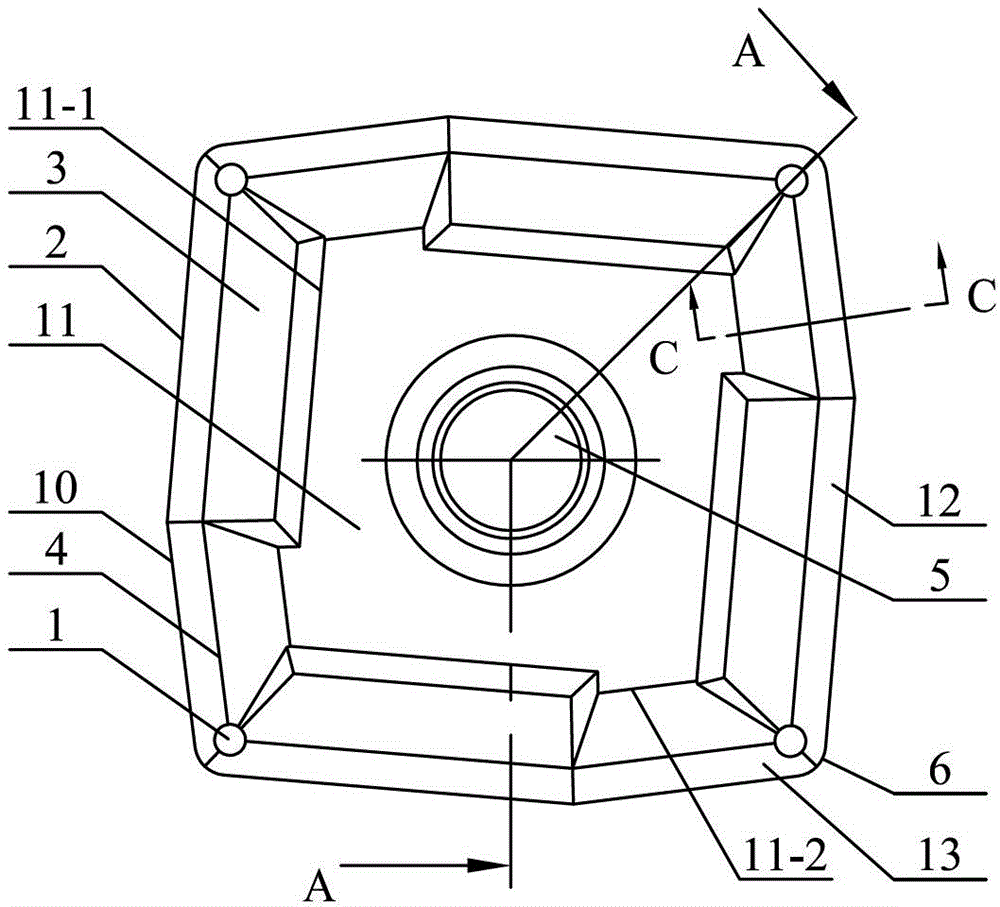

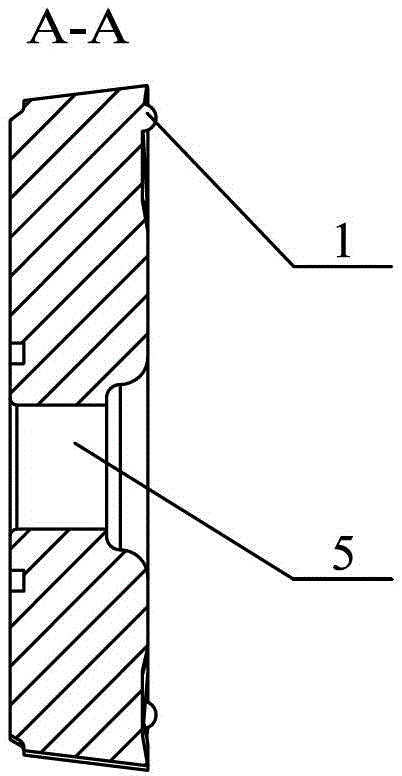

[0016] Specific implementation mode one: as Figure 1-Figure 6 As shown, in the heavy-duty high-efficiency cutting turn-milling compound broken-line edge insert of the present embodiment, the shape of the insert is a square truss shape, and the area of the bottom knife face of the insert is smaller than the area of the rake face of the insert, and the four flanks of the insert are (that is, the side of the blade) are all convex folding surfaces, and each convex folding surface is composed of a long slope 9-1 and a short slope 9-2, and the four flanks are composed of four long slopes 9-1 and four The short bevels 9-2 are alternately connected in sequence, each long bevel 9-1 is provided with a long cutting edge 2 at the intersection with the blade rake face, and each short bevel 9-2 is provided with a short cutting edge at the intersection with the blade rake face 10. The combination of the long cutting edge 2 and the short cutting edge 10 located on the same flank face con...

specific Embodiment approach 2

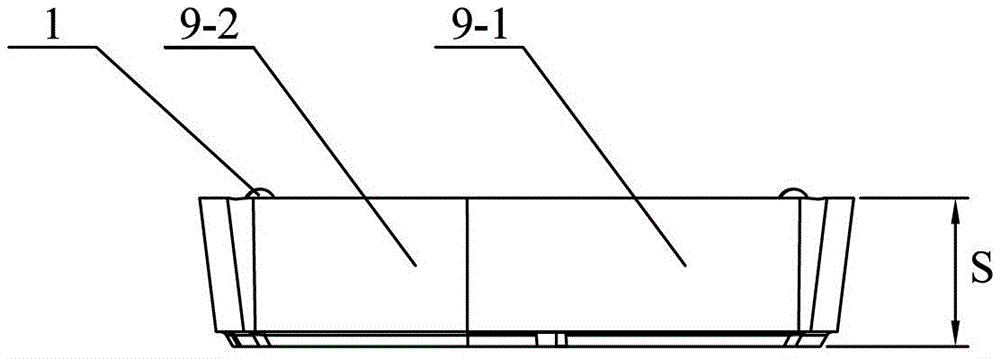

[0017] Specific embodiment two: combine figure 1 Note that the thickness S of the blade described in this embodiment is 10 mm. Can meet the strength requirements of the blade. The undisclosed technical features in this embodiment are the same as those in the first embodiment.

specific Embodiment approach 3

[0018] Specific embodiment three: the relief angle of the blade described in this embodiment is 6~8°. A preferred relief angle is 7°. The undisclosed technical features in this embodiment are the same as those in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com