Method for welding plate tubes and toothed plates of plate type evaporation heat exchanger

A technology of plate evaporation and welding method, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problems of poor welding quality and shortened service life of equipment, to avoid stress corrosion, reduce welding stress, and ensure tightness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

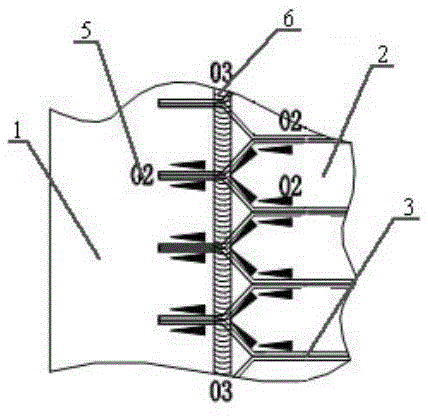

[0020] As shown in the figure, the welding method of the plate tube and tooth plate of the plate evaporative heat exchanger, the specific operation steps are as follows:

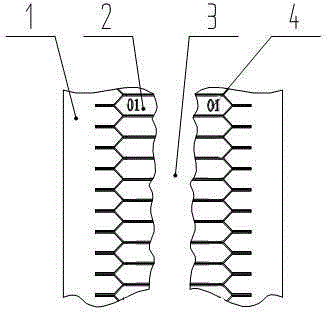

[0021] 1) Welding of plate tube and plate tube

[0022] 1) Clean up the area to be welded on the plate tube, then assemble the plate tube and the plate tube, and fix the position of the plate tube and the plate tube by tack welding;

[0023] 2) Weld along the weld between the plate tube and the plate tube until the plate tube and the plate tube are welded into a plate bundle with an integrated structure. The distance between them is 5~6mm;

[0024] The welding adopts manual argon arc welding, the welding sequence follows the "one" type welding, the type of power supply is DC, the polarity is positive connection, the diameter of the tungsten pole is φ2.5mm, the diameter of the nozzle is 8-10mm, and the welding method is self-melting. The welding current is 30-40A, the arc voltage is 12-14V, and the weld...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com