Scroll compressor cross-shaped slip ring fixture

A scroll compressor, cross slip ring technology, applied in clamping, manufacturing tools, metal processing machinery parts, etc. The effect of ensuring machining accuracy and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

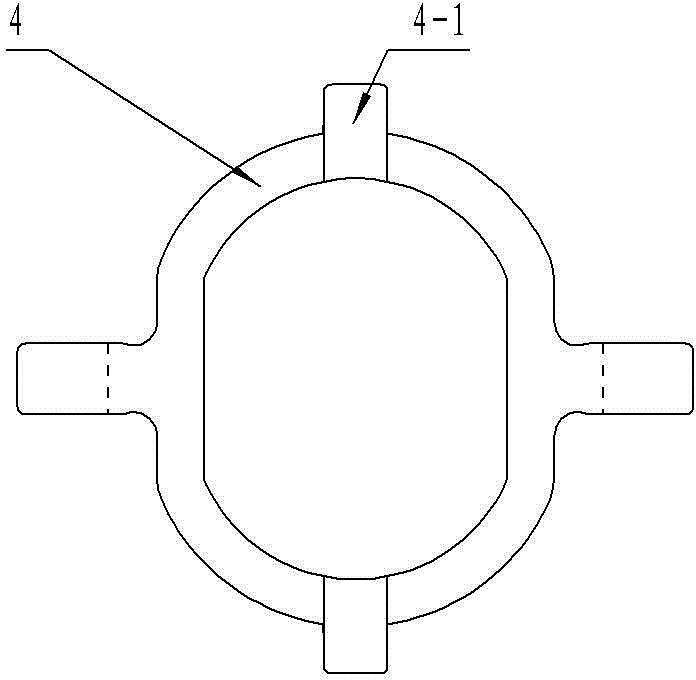

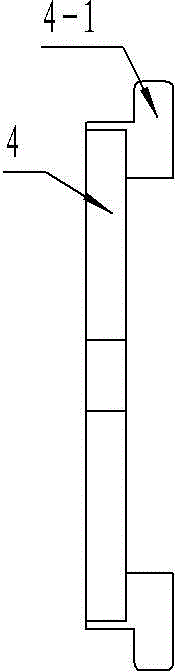

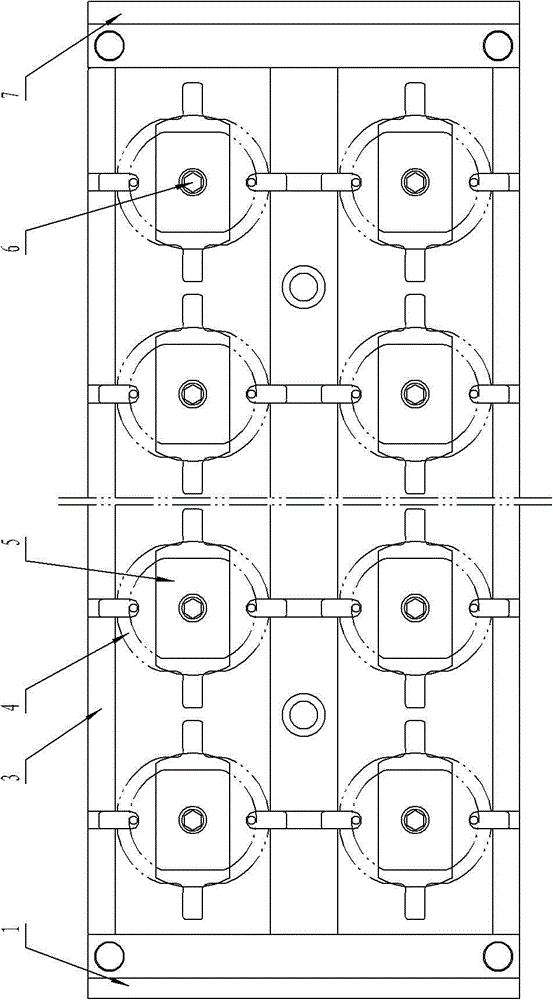

[0016] The shape of workpiece Oldham slip ring 4 is as follows figure 1 and figure 2 shown. like image 3 and Figure 4 The scroll compressor Oldham slip ring fixture shown includes a plate-shaped mounting seat 3, and the two ends of the mounting seat 3 are respectively fixed with support frames 1 and 7 by screws; the top surface of the mounting seat 3 is evenly arranged with two rows A total of 12 workpiece positioning through holes 3-2 and corresponding positioning grooves 3-1 are provided on the top surface of the mounting seat 3 according to the size of the boss 4-1 of the Oldham slip ring 4, and a positioning groove 3-1 is provided above the positioning through holes 3-2. Pressing plate 5, pressing plate 5 is connected with cylinder 2 ejector rods that are contained in the mounting base 3 bottom surface by passing through the fixing screw 6 of positioning through hole 3-2.

[0017] The structure of the mount 3 is as Figure 5 Shown; The structure of pressing plate 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com