Milling cutter grinding machine

A grinding machine and grinding mechanism technology, applied in milling cutters, grinding machine parts, milling machine equipment, etc., can solve the problem of high labor intensity of workers, and achieve the effect of simplifying the feeding process, high work efficiency, and reducing labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below with reference to the embodiments and the accompanying drawings, and the contents mentioned in the embodiments are not intended to limit the present invention.

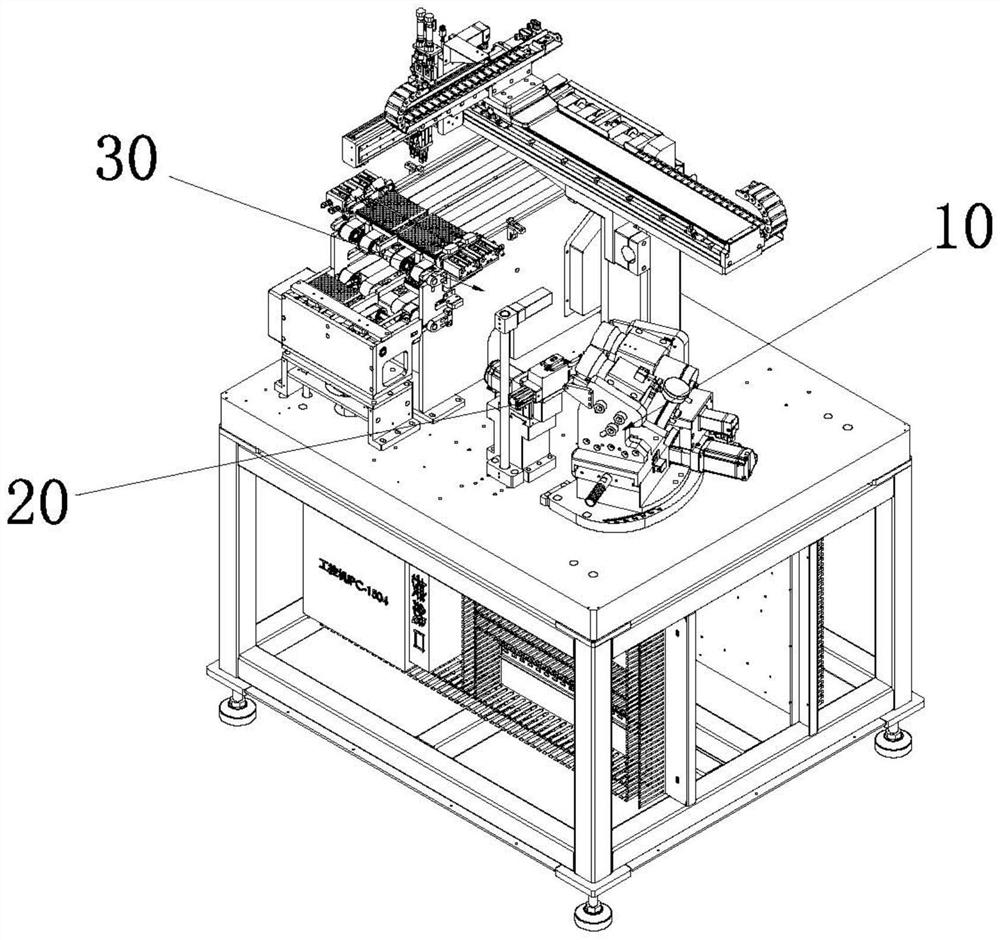

[0038] For the specific implementation of a milling cutter grinding machine of the present application, please refer to figure 1 , the milling cutter grinding machine includes a feeding mechanism 30, a grinding mechanism 10, a pressing mechanism 20 and a transfer robot (not shown) for transferring the feeding rod. Specifically, the grinding mechanism 10 is arranged on the side of the feeding mechanism 30, which can reduce the transfer distance of the material bar, and the pressing mechanism 20 is arranged between the grinding mechanism 10 and the feeding mechanism 30, which is convenient for grinding the material bar. The transfer robot is used to transfer the material bar on the feeding m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com