A Control System of Automatic Chemical Etching Machine for Silicon Wafer

An automatic chemical and corrosion machine technology, applied in the direction of program control manipulators, manipulators, manufacturing tools, etc., can solve the problems of cumbersome procedures, corrosion of polishing sheets, etc., and achieve the effects of avoiding system failures, improving quality, and increasing pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

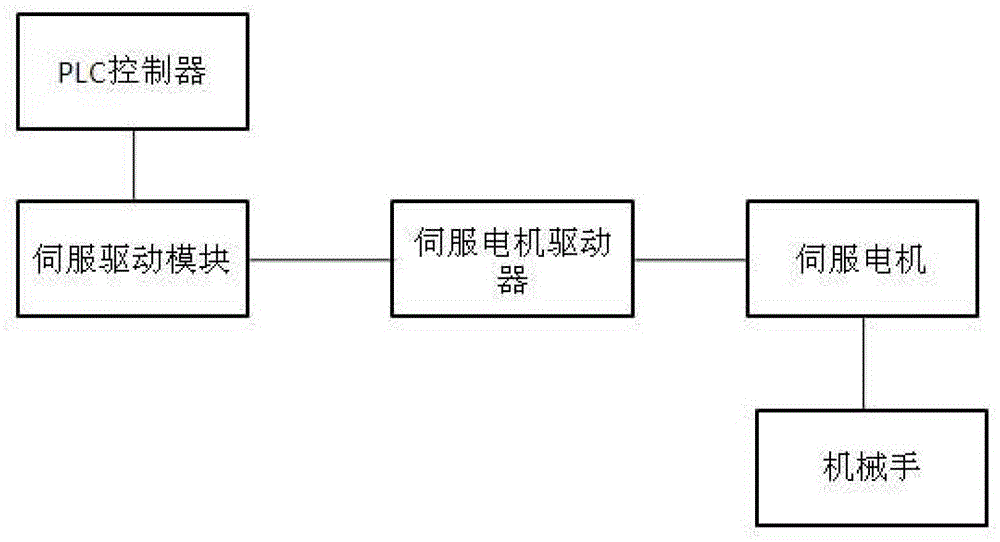

[0014] Such as figure 1 As shown, the present invention comprises manipulator, is characterized in that: also comprises servo motor, servo motor driver, servo drive module and PLC controller, and described PLC controller is connected with described servo drive module, and described servo drive module also described servo drive module The motor driver is connected, the servo motor driver is connected to the motor, and the servo motor is connected to the manipulator.

[0015] The servo drive module is connected to the servo motor driver through an optical fiber transmission line.

[0016] The model of the servo motor driver is MR-J3-200B.

[0017] The model of the servo drive module is Qd75MH-1.

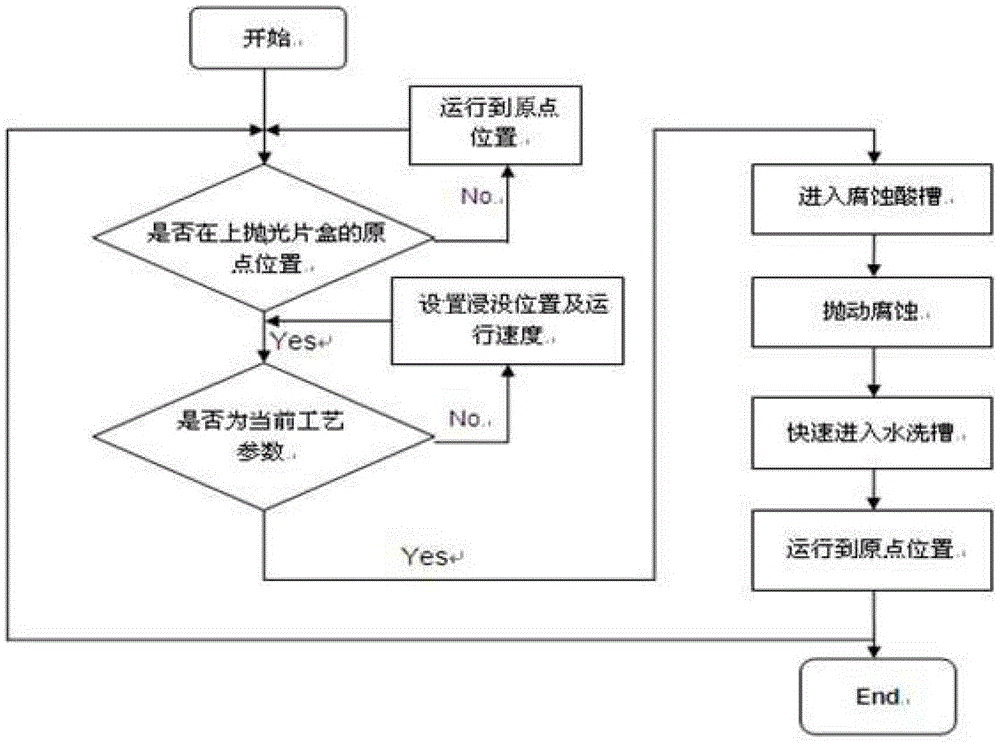

[0018] The working process of this example: based on the various requirements in the production process, set the operating parameters on the PLC controller, and the PLC controller reads these parameters to give instructions to the servo drive module; the instructions include the spee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com