Optical fiber communication system capable of monitoring multiple mining conveyor belts

An optical fiber communication system and conveyor belt technology, applied in transmission systems, signal transmission systems, electromagnetic wave transmission systems, etc., can solve the problems of complex electromagnetic environment, easy to be interfered, and large interference, achieve high data transmission rate, avoid system failure, Good anti-interference effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] A preferred embodiment of the optical fiber communication system capable of monitoring a plurality of mine conveyor belts is described in detail as follows:

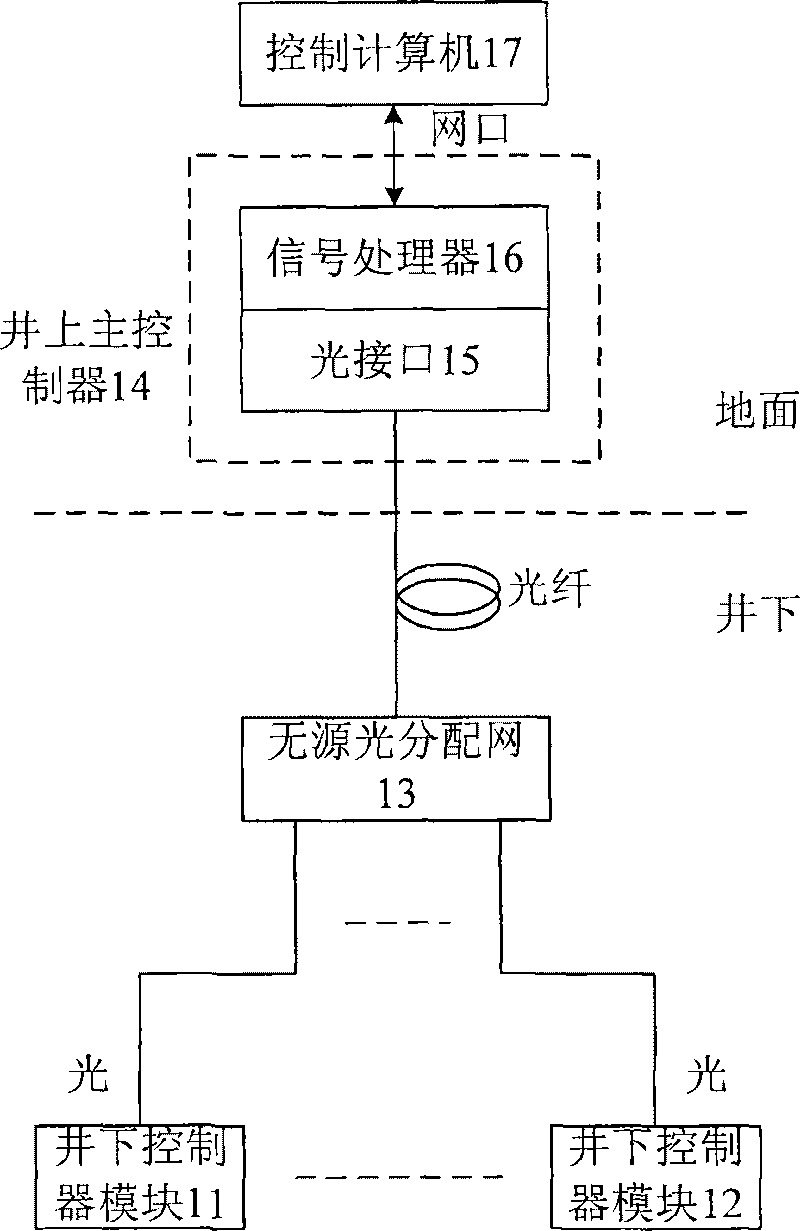

[0021] see image 3 , in the uplink direction, an optical signal of a certain wavelength (generally 1310 nm) sent by the downhole control modules 11 and 12 is sent to the uphole master controller 14 through the passive optical splitter 13 . Since there are multiple downhole control modules sharing one wavelength, the downhole control modules should send optical signals in time-sharing, and which downhole control module sends the signal is determined by the uphole main controller, ensuring that no conflicts will occur. The main controller on the well sends the downhole control module signal received by the optical interface 15 to the control computer 17 through the Ethernet port for storage and processing after being processed by the data processor 16 .

[0022] In the downlink direction, after the control signal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com