Continuous cloth plate blank wet method cutting machine and operating method thereof

A cutting machine and slab technology, applied in chemical instruments and methods, lamination auxiliary operations, layered products, etc., can solve the problems of increased scrap rate, low bonding strength, uneven edges, etc., to achieve fully automatic production, The effect of improving processing efficiency and reducing cutting difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

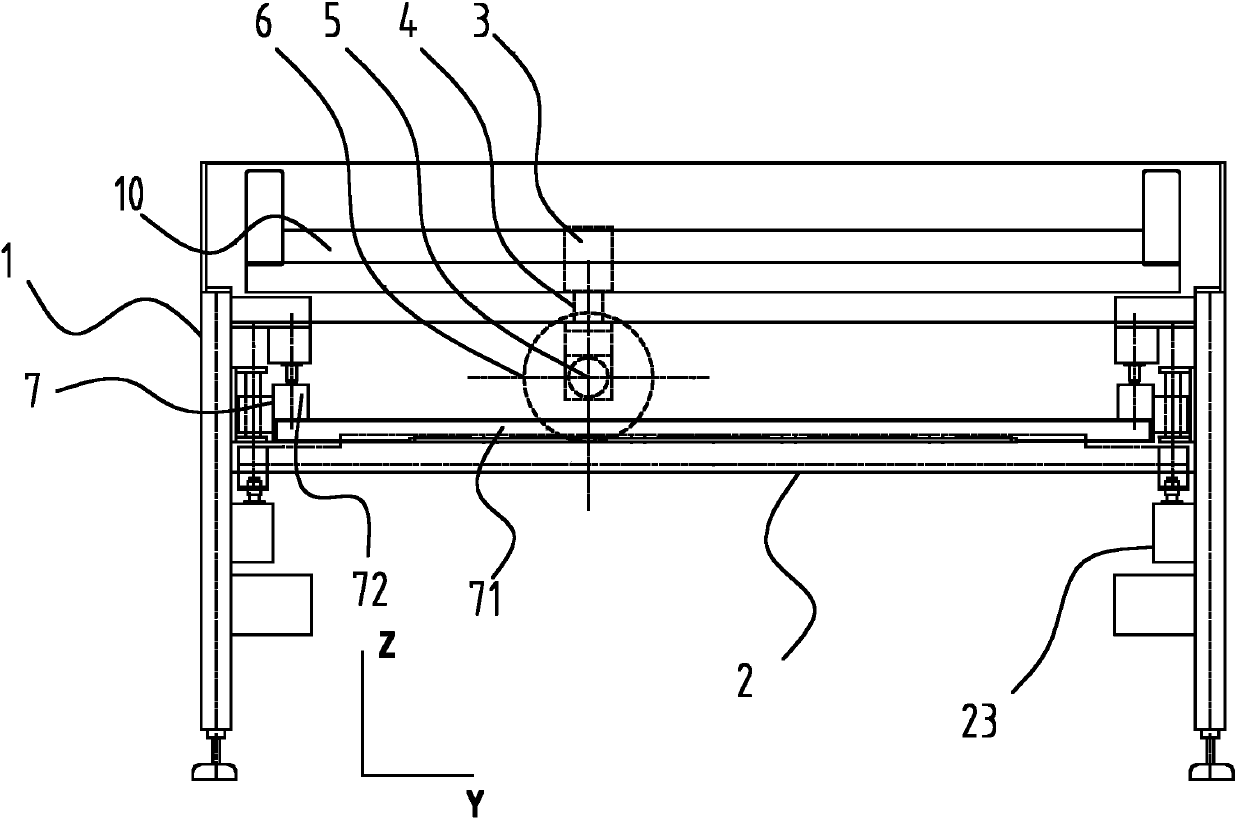

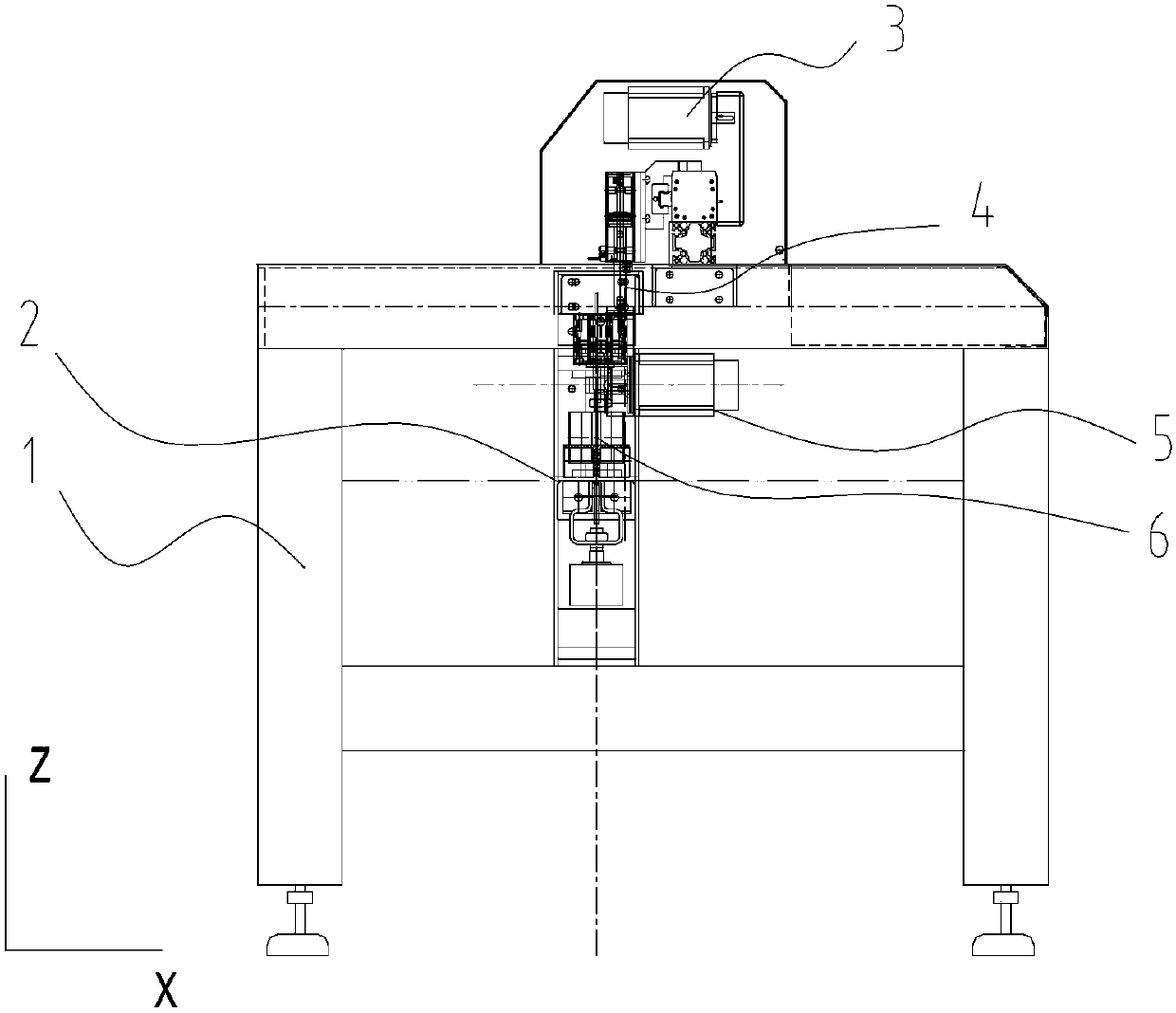

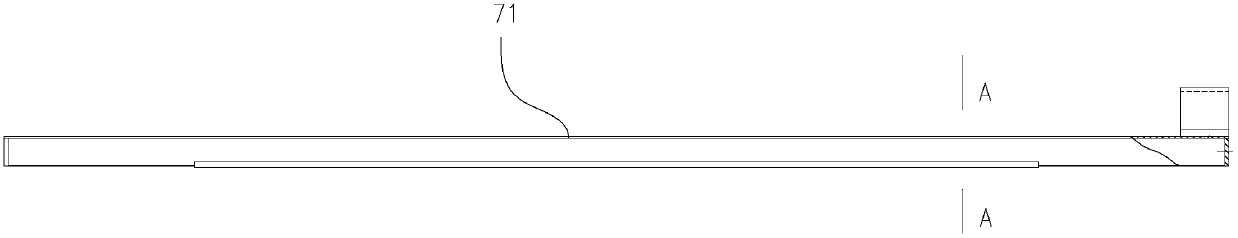

[0042] The invention is like Figure 1-11 As shown, it includes a frame 1, a workbench 2, a tool holder walking mechanism 3 moving in the Y direction, and a tool holder lifting mechanism 4 moving in the Z direction; the top of the frame 1 is provided with a Y-direction top beam 10; The bottom of the knife holder lifting mechanism 4 is provided with a knife holder 5 connected with a cutter 6;

[0043] The tool post walking mechanism 3 is movably connected to the top beam 10 of the frame 1 for reciprocating movement in the Y direction; the tool post walking mechanism 3 includes a walking motor moving in the Y direction and a suspension arm arranged in the Z direction The suspension arm is connected to the top beam by a walking motor;

[0044] The tool holder lifting mechanism 4 is fixedly connected to the bottom of the tool holder walking mechanism 4 to drive the cutter 6 to move in Z-direction; the tool holder lifting mechanism includes a tool holder lifting cylinder and a connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com