Integral sludge solidification ship

A sludge and curing agent technology, which is applied in special purpose ships, climate change adaptation, dehydration/drying/thickened sludge treatment, etc., can solve the problems of site constraints, limited sludge solidification efficiency, high fixed investment cost, etc., and achieve transmission Stability, good engineering characteristics, and the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with accompanying drawing.

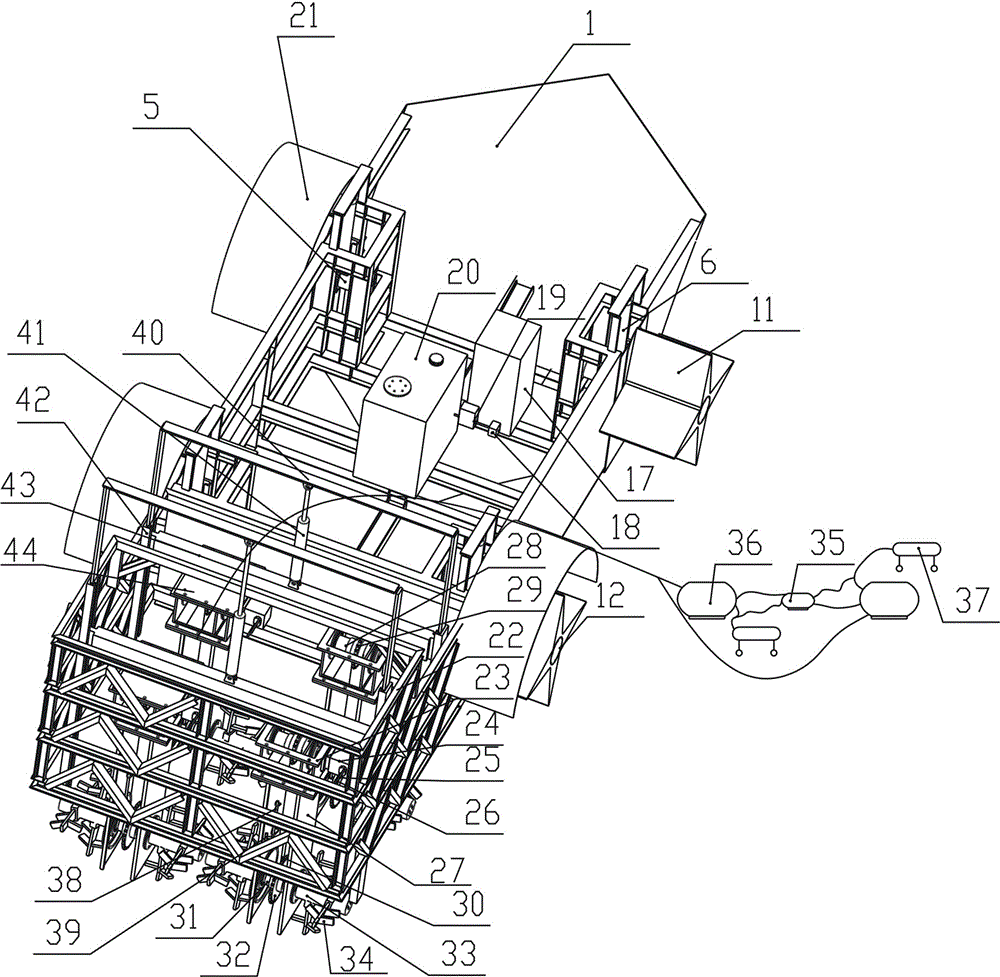

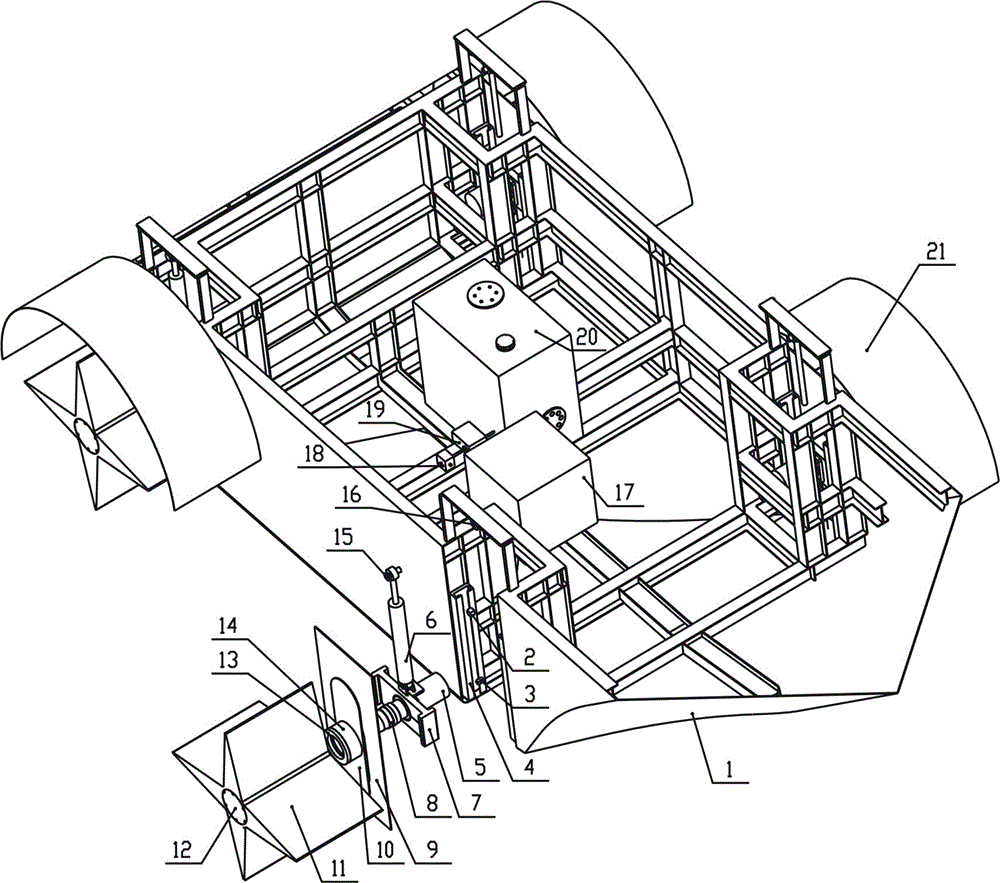

[0033] figure 1 The structural diagram of the silt solidification ship in this embodiment is shown, and the silt solidification ship includes a flat-bottomed hull 1, a walking device, a stirring device, a curing agent delivery device, and a power system, and the hull 1 is welded by I-beams, Two pairs of square grooves are symmetrically arranged on both sides of the hull 1, and a running device is installed in each square groove, and an installation frame is arranged at the end of the hull 1, and 4 agitators are installed on the installation frame. device, the power system provides a power source for the walking device and the stirring device.

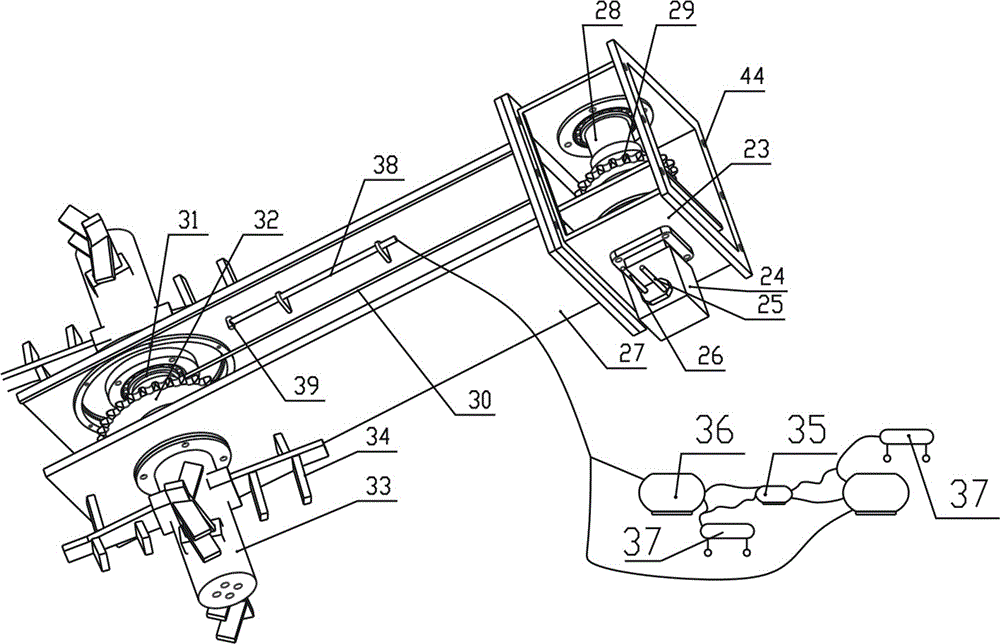

[0034] like figure 2 As shown, the running device includes a flat impeller 11, an intermediate shaft 8 connected to the impeller 11, an impeller driving device connected to the intermediate shaft 8, a static sealing plate 9, an im...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com