Method of preparing iron oxide yellow by using titanium dioxide by-product

A technology of iron oxide yellow and by-products, applied in the direction of iron oxide/iron hydroxide, etc., can solve the problems of ineffective control of seed nucleation and growth of crystal nuclei, influence of iron oxide yellow color, mixed cylindrical seeds, etc. , achieve high tinting strength, improve dispersibility, and good impurity removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

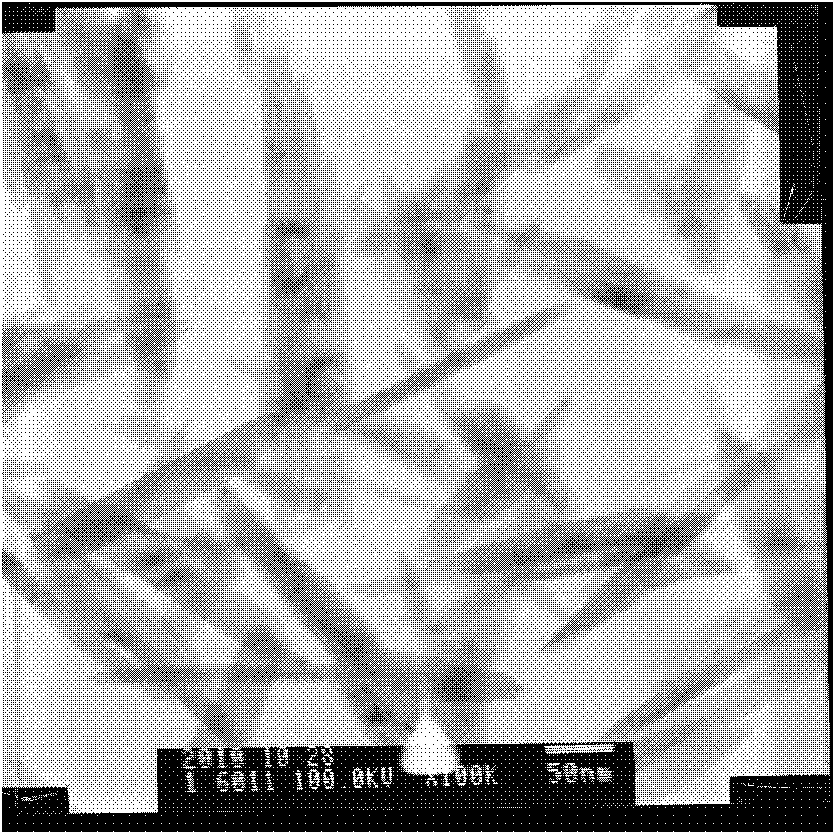

Image

Examples

Embodiment 1

[0046] (1) Refining of ferrous sulfate

[0047] At 10°C, use titanium dioxide by-product ferrous sulfate to prepare 500ml of ferrous sulfate heptahydrate solution with a concentration of 350g / L, adjust the pH value of the solution to 1 with sulfuric acid, and carry out titanium dioxide by-product ferrous sulfate. Hydrolysis treatment to generate Ti 2 O·H 2 O complexes;

[0048] Add 0.09g of polyacrylamide to the above solution, stir and filter after standing to settle to remove Ti 2 O·H 2 O complex, the filtrate is the refined ferrous sulfate solution;

[0049] (2)Fe(OH) 2 generation

[0050] Take 375ml of the refined ferrous sulfate solution and add 9g of 30wt% NaOH solution, carry out neutralization reaction at 10°C, control the pH value of the system to 6.0, and neutralize when the white precipitate generated in the solution turns dark green The reaction is over;

[0051] (3) Preparation of iron oxide yellow crystal seeds

[0052] It is 200g / L that the system solut...

Embodiment 2

[0059] (1) Refining of ferrous sulfate

[0060] At 50°C, use titanium dioxide by-product ferrous sulfate to prepare 500ml of ferrous sulfate heptahydrate solution with a concentration of 350g / L, adjust the pH value of the solution to 1.5 with sulfuric acid, and carry out titanium dioxide by-product ferrous sulfate. Hydrolysis treatment to generate Ti 2 O·H 2 O complexes;

[0061] Add 0.09g of polyacrylamide flocculant to it, stir and filter after standing to settle to remove Ti 2 O·H 2 O complex, the filtrate is the refined ferrous sulfate solution;

[0062] (2)Fe(OH) 2 generation

[0063] Take 375ml of the refined ferrous sulfate solution and add 9.5g 30wt% NaOH solution, carry out neutralization reaction at 20°C, control the pH value of the system to 6.5, and neutralize the reaction when the white precipitate generated in the solution turns dark green End;

[0064] (3) Preparation of iron oxide yellow crystal seeds

[0065] It is 250g / L that the system solution afte...

Embodiment 3

[0072] (1) Refining of ferrous sulfate

[0073] At 60°C, use titanium dioxide by-product ferrous sulfate to prepare 500ml of ferrous sulfate heptahydrate solution with a concentration of 400g / L, adjust the pH value of the solution to 2.0 with sulfuric acid, and carry out titanium dioxide by-product ferrous sulfate. Hydrolysis treatment to generate Ti 2 O·H 2 O complexes;

[0074] Add 0.1g of polyacrylamide flocculant to it, stir, settle and filter to remove Ti 2 O·H 2 O complex, the filtrate is the refined ferrous sulfate solution;

[0075] (2)Fe(OH) 2 generation

[0076] Get the ferrous sulfate solution 375ml after described refinement, add the NaOH solution of 12g 30wt%, carry out neutralization reaction at 30 ℃, control system pH value to be 7.0, when the white precipitate of generation in the solution turns dark green, neutralize and the reaction ends;

[0077] (3) Preparation of iron oxide yellow crystal seeds

[0078] It is 300g / L that the system solution after th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com