Double-liquid process grouting material and grouting process using grouting material

A grouting material and process technology, applied in infrastructure engineering, construction, etc., can solve the problems of long setting time of grouting material, difficult to control setting time, and uncontrollable method of adding, so as to reduce the amount of cement, low cost, and fill cracks. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

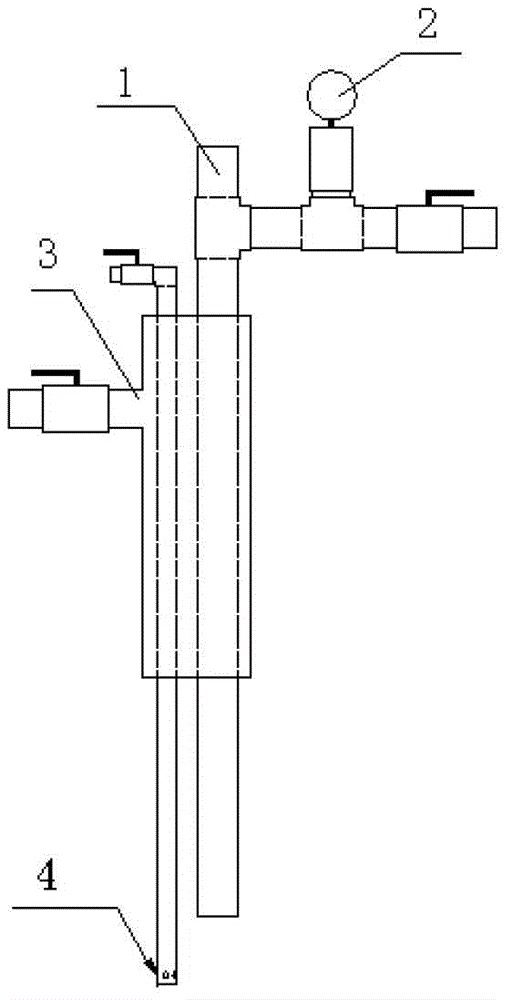

Image

Examples

Embodiment 1

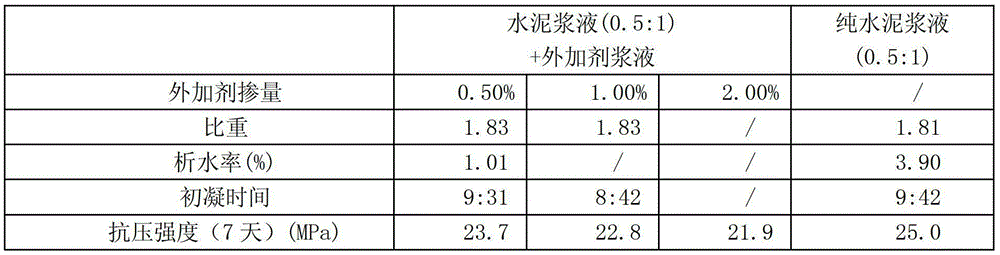

[0026] grouting material

[0027] In the field grouting construction, mix 0.5:1 cement slurry with admixture solution, the admixture solution is prepared from water and admixture at a weight ratio of 9:2, and the admixture is composed of sodium metasilicate 0.38 0.12 parts of potassium lithium and 0.5 parts of calcium chloride.

[0028] During the grouting construction, it is strictly controlled according to the weight ratio of cement grout and admixture aqueous solution injection ratio of 40:6.

[0029] Construction process

[0030] Prepare the cement slurry and admixture solution according to the following steps and then carry out two-liquid method grouting:

[0031] (1) Preparation of additives: Add the following components in parts by weight into the container and stir evenly, sodium metasilicate: 0.38 parts, potassium lithium oxide: 0.12 parts; calcium chloride: 0.5 parts;

[0032] (2) Preparation of admixture solution: 0.18 parts by weight of admixture prepared in ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com