Anti-ultraviolet finishing method

An anti-ultraviolet and finishing liquid technology, applied in the field of dyeing and finishing, can solve the problems of poor rain resistance and high price, and achieve the effects of easy operation, energy saving and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

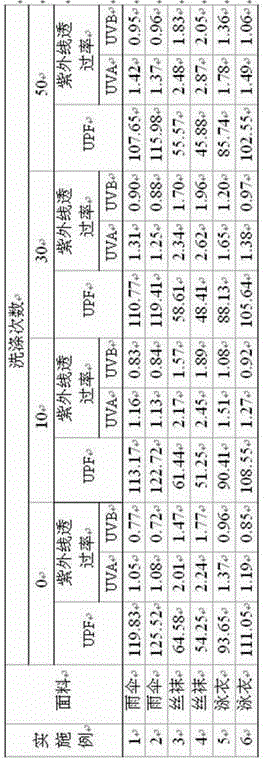

Examples

Embodiment 1

[0017] An anti-ultraviolet finishing method, the finishing process is: dissolving the dispersed ultraviolet absorber Rayosan P in water to prepare a finishing solution, then adding the reactive ultraviolet absorber Rayosan C to the above finishing solution, and then adding Sodium chloride, when the temperature of the finishing solution is 30°C, put the fabric of the polyester umbrella into the finishing solution, the dyeing bath ratio is 1:50, then raise the temperature to 40°C at a heating rate of 0.5°C / min, and add sodium carbonate to the finishing solution , keep warm for 20 minutes, then raise the temperature to 130 ℃ at a heating rate of 2 ℃ / min, keep warm for 30 minutes, and wash and dry fully after the heat preservation is completed. The finishing liquid prescription is as follows: dispersive UV absorber Rayosan P 5 % o.m.f, reactive UV absorber Rayosan C 2 % o.m.f, sodium chloride 40g / L, sodium carbonate 0.5g / L.

Embodiment 2

[0019] An anti-ultraviolet finishing method, the finishing process is: dissolving the dispersed ultraviolet absorber Rayosan P in water to prepare a finishing solution, then adding the reactive ultraviolet absorber Rayosan C to the above finishing solution, and then adding Sodium chloride, when the temperature of the finishing solution is 30°C, put the fabric of the polyester umbrella into the finishing solution, the dyeing bath ratio is 1:20, then raise the temperature to 40°C at a rate of 1°C / min, and add sodium carbonate to the finishing solution , keep warm for 30 minutes, then raise the temperature to 120 ℃ at a heating rate of 1 ℃ / min, keep warm for 40 minutes, and wash and dry fully after the heat preservation is completed. The finishing liquid prescription is as follows: dispersive UV absorber Rayosan P 8 % o.m.f, reactive UV absorber Rayosan C 4 % o.m.f, sodium chloride 50g / L, sodium carbonate 1.5g / L.

Embodiment 3

[0021] An anti-ultraviolet finishing method, the finishing process is: dissolving the dispersed ultraviolet absorber Rayosan P in water to prepare a finishing solution, then adding the reactive ultraviolet absorber Rayosan C to the above finishing solution, and then adding Sodium chloride, when the temperature of the finishing solution is 30°C, put nylon core-spun silk stockings into the finishing solution, the dyeing bath ratio is 1:50, then raise the temperature to 40°C at a heating rate of 0.5°C / min, add sodium carbonate to the finishing solution, Keep warm for 40 minutes, then raise the temperature to 100°C at a heating rate of 1°C / min, keep warm for 30 minutes, and wash and dry fully after the heat preservation is over. The finishing liquid prescription is as follows: dispersive UV absorber Rayosan P 5 % o.m.f, reactive UV absorber Rayosan C 5 % o.m.f, sodium chloride 50g / L, sodium carbonate 0.5g / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com