Split heat-insulation double-sided water pump impeller

A double-sided impeller and impeller technology, which is applied to the components, pumps, and pump components of the pumping device for elastic fluids, can solve the problems of large temperature influence, harsh working environment of the engine, and influence on the reliability of the engine, and can meet the requirements of Long-term work, reduced interaction, effect of reduced temperature interaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The preferred embodiment of the present invention is described in detail in conjunction with accompanying drawing:

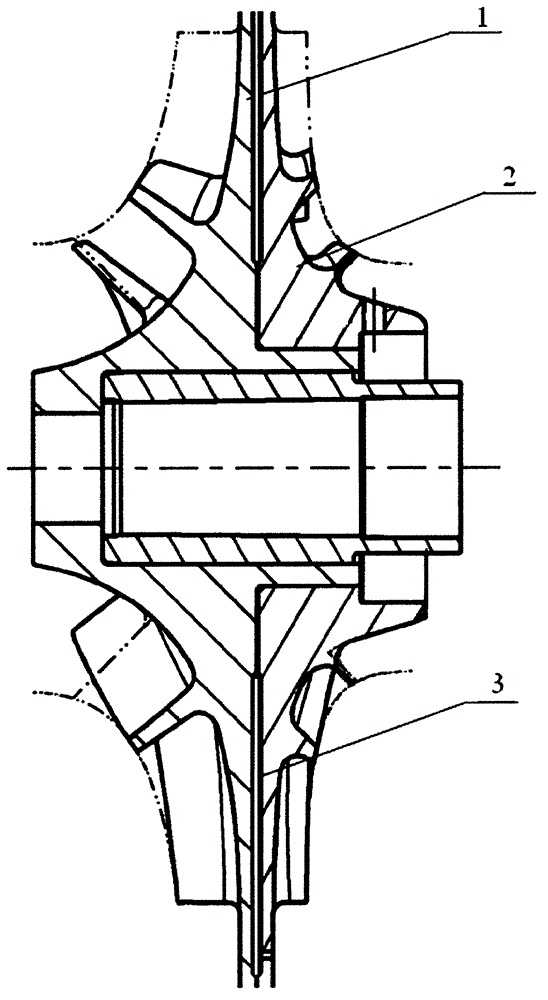

[0015] Such as figure 1 As shown, a split-type heat-insulated double-sided impeller structure includes a large impeller 1 and a small impeller 2. The large impeller 1 and the small impeller 2 are assembled in an axial interference fit. After the large impeller 1 and the small impeller 2 are assembled, the impeller A heat insulation structure 3 is formed at the back of the wheel, and the end surface of the heat insulation structure 3 is sprayed with a zirconia coating.

[0016] In order to improve the heat insulation effect, the thickness of the heat insulation structure 3 is preferably 3-5 mm.

[0017] In order to further improve the heat insulation effect, it is preferable that the materials of the large impeller 1 and the small impeller 2 are engineering plastics.

[0018] The present invention also has another embodiment:

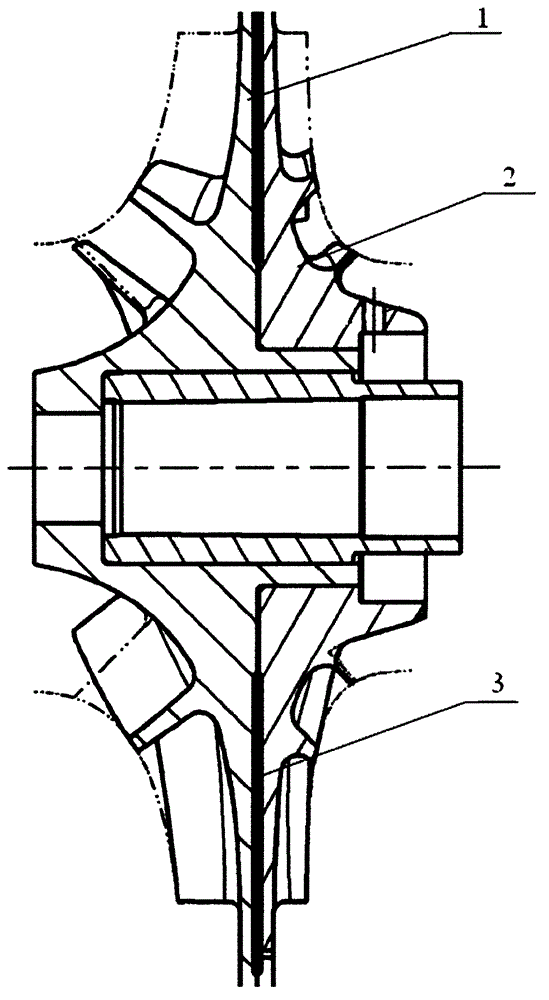

[0019] Such as figure 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com