Measuring and cleaning device suitable for microelement detection

A cleaning device and trace element technology, which is applied in the field of measuring equipment and polarographic chemical analysis, can solve the problems of mercury volatilization pollution cleaning and difficult control, and achieve the effect of reducing residue, reducing volatilization and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

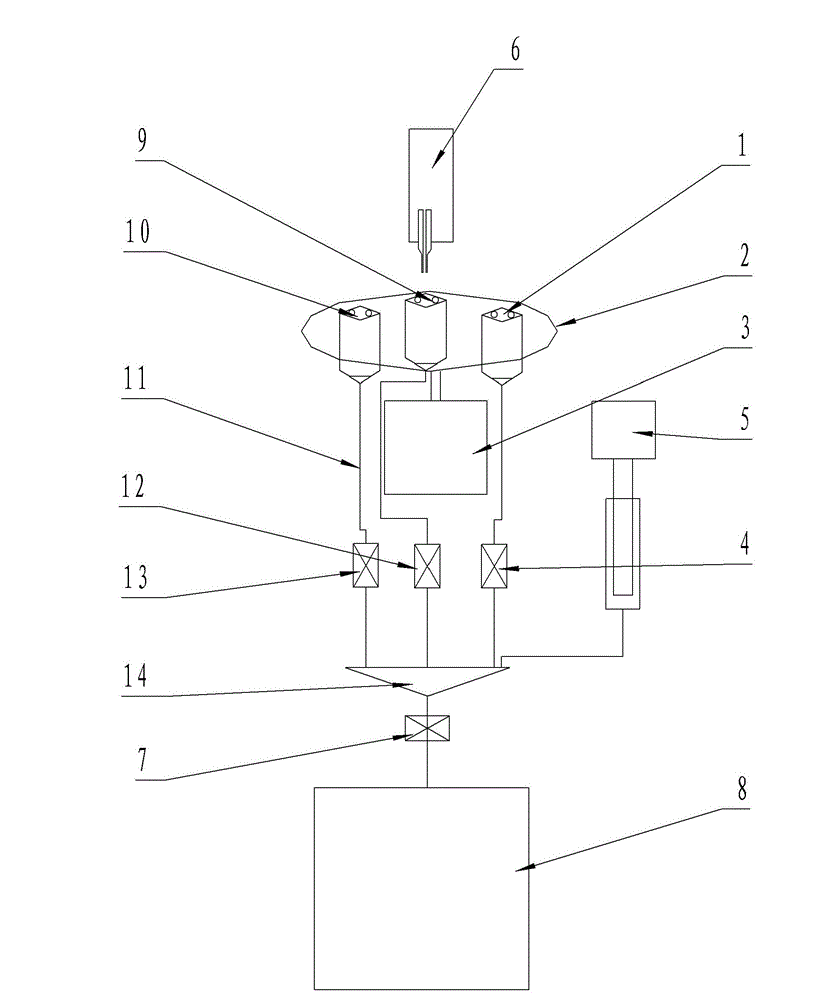

[0017] Embodiment 1, a kind of measuring and cleaning device that is suitable for trace element detection, comprises the polarographic measuring plate 2 that measuring cup is housed and is positioned at the polarographic electrode 6 above the polarographic measuring plate, reagent adding device, it is characterized in that: measure Cup A1, measuring cup B9, and measuring cup C10 are closely arranged on the same circular arc with the center of the polarographic measuring disc as the center. The valve C13 is connected with the sealed connector 14, the pipeline at the bottom of the connector is connected to the waste liquid bucket 8 through the waste liquid bucket solenoid valve 7, the plunger vacuum pump 5 is connected to the connector, and a step is installed under the polarographic measuring plate. Enter motor 3.

[0018] The flexible catheter is a silicone catheter. The solenoid valve is a pinch valve.

Embodiment 2

[0019] Embodiment 2, a kind of measuring and cleaning device that is suitable for trace element detection, comprises the polarographic measuring disk 2 that measuring cup is housed and is positioned at the polarographic electrode 6 above the polarographic measuring disk, reagent adding device, it is characterized in that: Cup A1, measuring cup B9, and measuring cup C10 are closely arranged on the same circular arc with the center of the polarographic measuring disc as the center. The valve C13 is connected with the sealed connector 14, the pipeline at the bottom of the connector is connected to the waste liquid bucket 8 through the waste liquid bucket solenoid valve 7, the plunger vacuum pump 5 is connected to the connector, and a step is installed under the polarographic measuring plate. Enter motor 3.

[0020] The flexible catheter is a silicone catheter. The solenoid valve is a pinch valve.

[0021] The step angle of the stepping motor is the angle between two adjacent me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com