Signal conditioning circuit for detecting thickness of yarn

A signal conditioning circuit and thickness technology, applied in the field of electronic technology applications, can solve the problems of high cost of PGA circuit, multi-cut, signal zero drift, etc., to achieve intelligent zero adjustment and gain control, overcome environmental changes and solve zero. The effect of bit drift

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

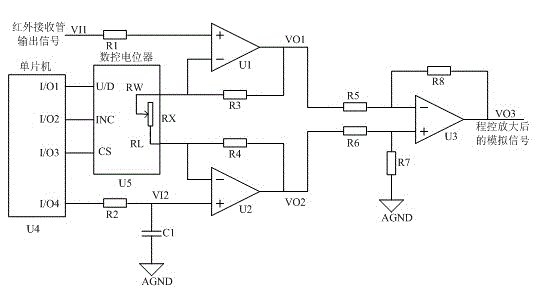

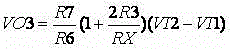

[0014] Such as figure 1 As shown, a signal conditioning circuit for yarn thickness detection includes a digital control potentiometer control circuit, a DC zero-adjustment signal generation circuit, and an instrumentation amplifier circuit.

[0015] The digital control potentiometer control circuit includes single-chip microcomputer STM8S105C6T6 chip U4 and numerical control potentiometer X9313WS chip U5; the I / O1 port of the single-chip microcomputer STM8S105C6T6 chip U4 is connected to the U / D pin of the numerical control potentiometer, and the I / O2 port of the single-chip microcomputer STM8S105C6T6 chip U4 is connected to the digital control potentiometer The INC pin of the potentiometer is connected, and the I / O3 port of the STM8S105C6T6 chip U4 is connected to the CS pin of the digital control potentiometer.

[0016] The DC zero-adjusting signal generating circuit includes a single-chip microcomputer STM8S105C6T6 chip U4, a second resistor R2 and a first capacitor C1; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com