Ridge waveguide filter with high micro discharging threshold value and design method thereof

A ridge waveguide and filter technology, applied in the field of ridge waveguide filter and its design, can solve problems such as failure of high-power microwave components, failure of payload, high electric field intensity, etc., to suppress micro-discharge effects, reduce volume and weight , the effect of high micro-discharge threshold

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

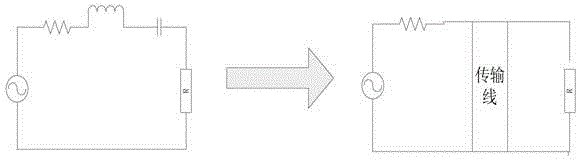

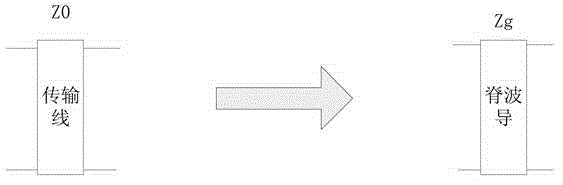

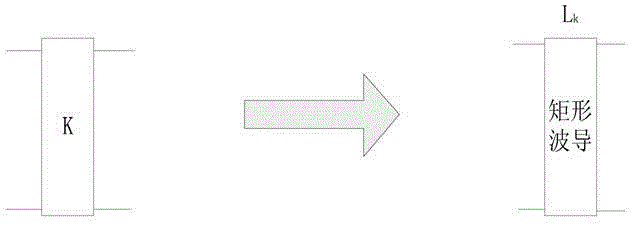

Method used

Image

Examples

Embodiment

[0036] Embodiment: In the range of 2.3-2.5GHz, the reflection loss is less than -20dB, and the commonly used ridge waveguide filter with insertion loss less than 0.15dB is an example. The design process of the ridge waveguide filter proposed by the present invention is as follows:

[0037] (1) According to the technical specifications, the cut-off frequency f c =2.5GHz, impedance R 0 =50Ω, insertion loss less than 0.15dB, etc. It is required to determine the filter order N=6, and determine the lumped parameter low-pass filter circuit through table lookup or calculation, such as Image 6 shown;

[0038] The value of the inductance element is shown in Table 1:

[0039] Table 1 Values of inductive components in lumped parameter filter circuits

[0040] L1

L2

L3

L4

L5

L6

31.08nH

84.93nH

116.0nH

116.0nH

84.93nH

31.08nH

[0041] The values of the capacitive components are shown in Table 2:

[0042] Table 2 Value...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com