Permanent magnetic classificator

A concentrator and permanent magnet technology, applied in the field of concentrators, can solve the problems of not meeting the quality standards of steel plants, high iron ore impurity content, and increased production costs, so as to reduce energy consumption, improve iron ore grade, and reduce Investment and Cost Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

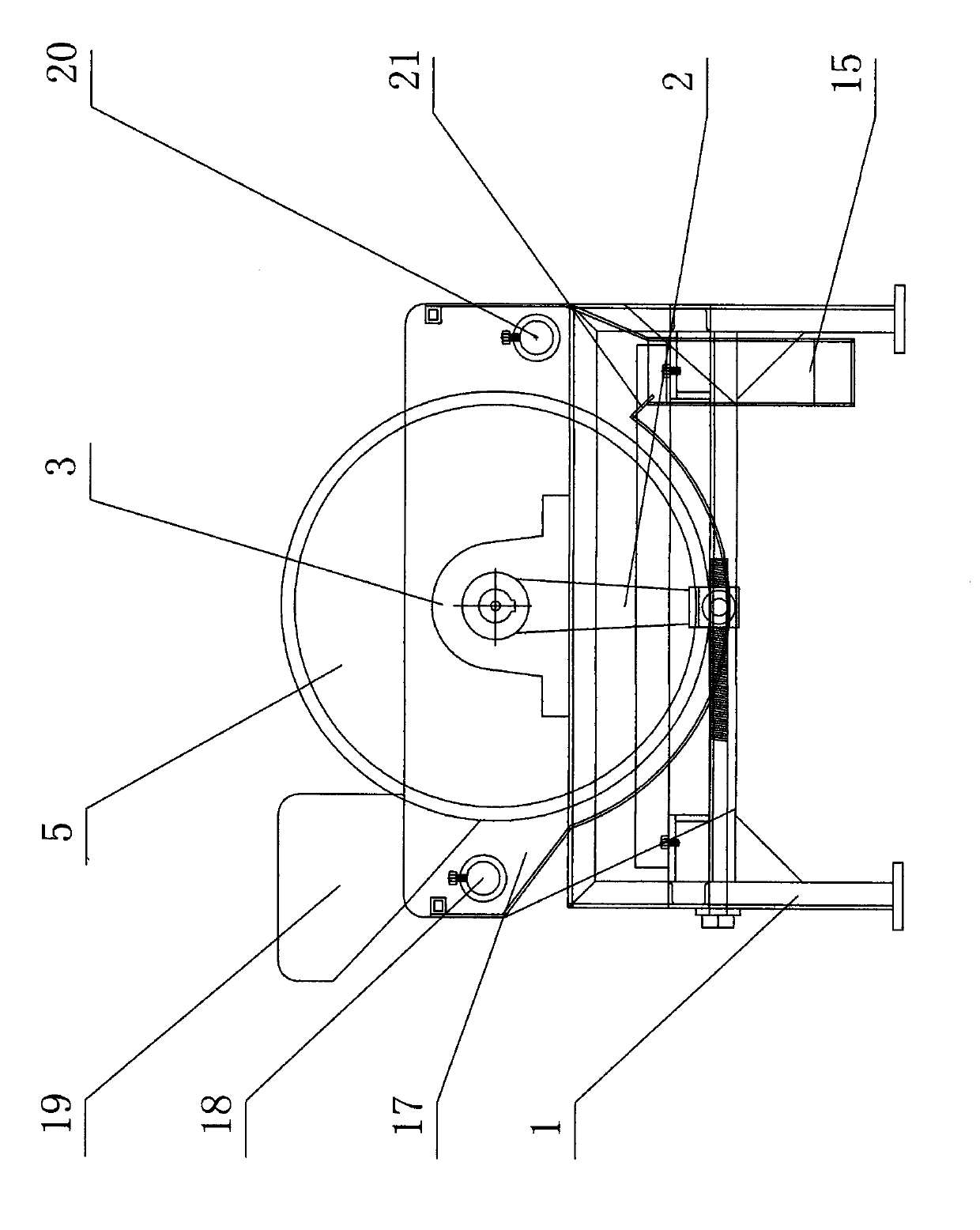

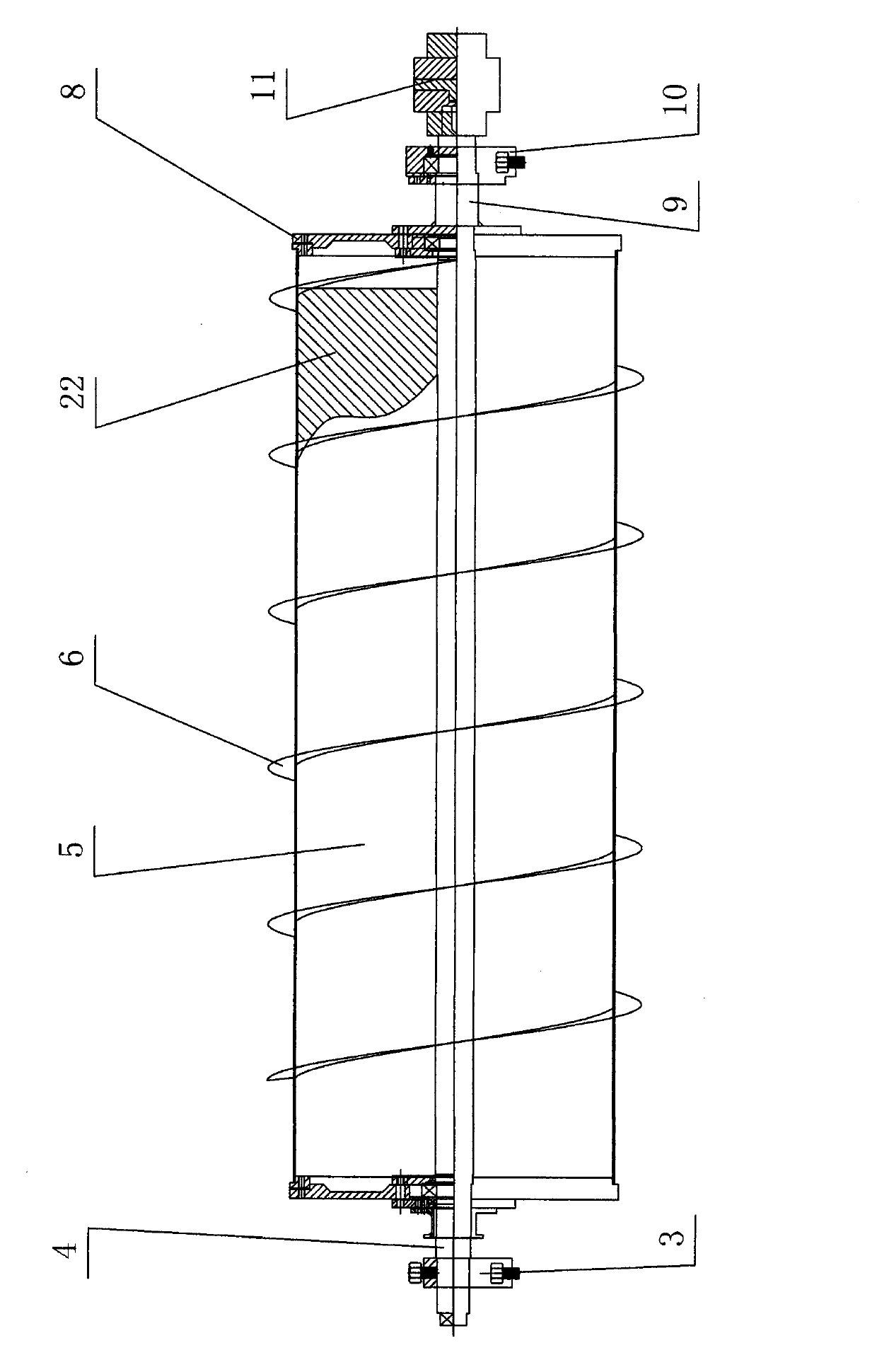

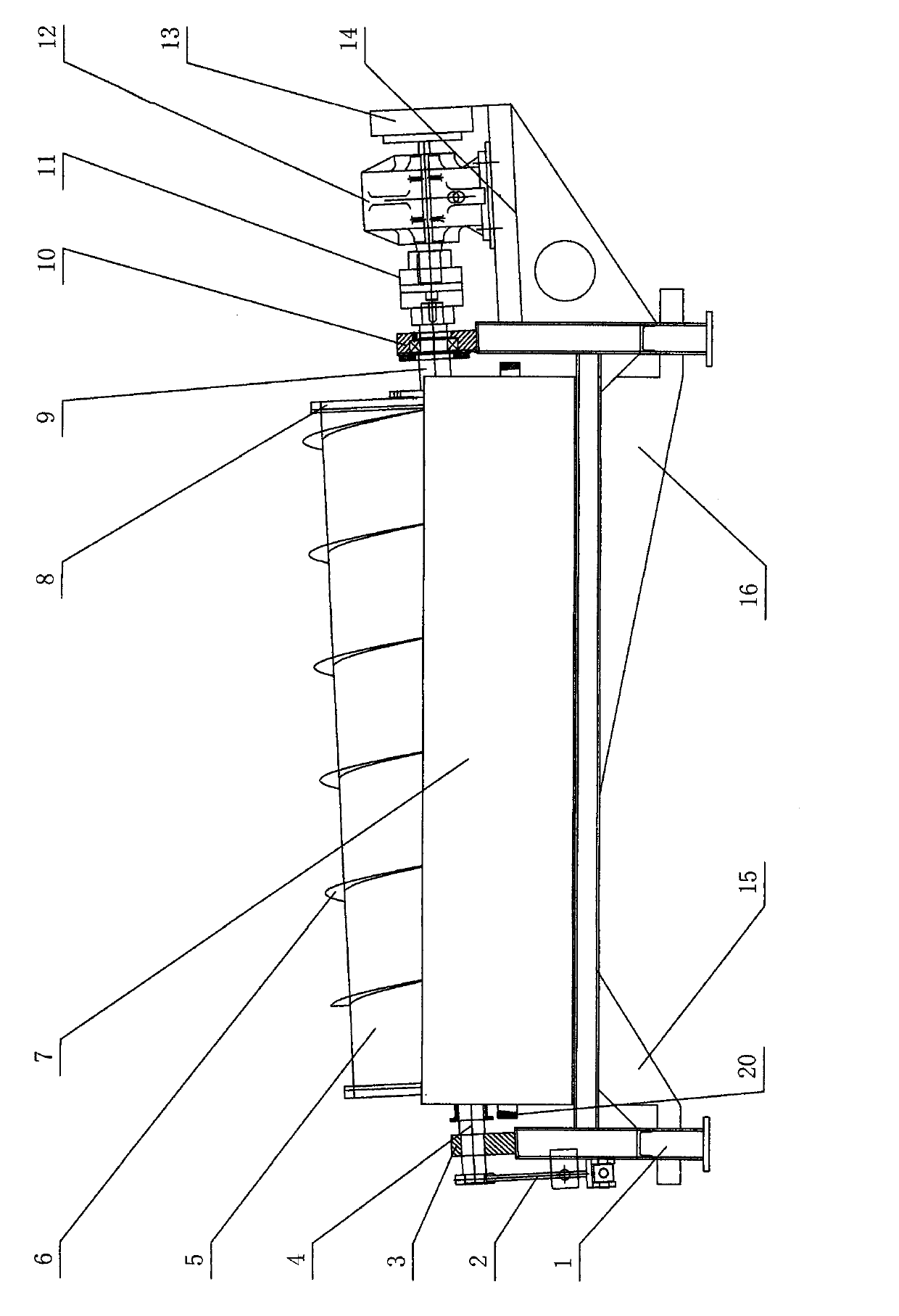

[0011] Referring to the accompanying drawings, the permanent magnet magnetic concentrator of the present invention comprises a main frame 1 and a power frame 14 connected to the main frame, a shaft coupling 11, a speed reducer 12, and an electric motor 13 mounted on the power frame 14 are mounted on the main frame. Frame 1 relies on the bearing housing 10 on one side of the power frame 14, the bearing seat 3 on the other side of the main frame 1, and the magnetic system adjustment device 2 composed of a wrench and a cardan shaft; Barrel device 5, feeding device 19, ore washing tank 17, ore unloading plate 21, ore discharge tank 7, concentrate unloading hopper 15, tailings unloading hopper 16, ore washing water pipe 18 drilled with spray holes, drilled with The ore unloading water pipe 20 with small water spray holes; wherein, the main frame 1 and the power frame 14 are welded by channel steel and angle steel according to the models of different specifications, and the output sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com