Water-based type screen cleaning machine

A cleaning machine, water-based technology, used in dryers, cleaning methods and utensils, cleaning methods using liquids, etc. problems, to achieve the effect of preventing heat loss, reducing comprehensive operating costs, and shortening heating time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

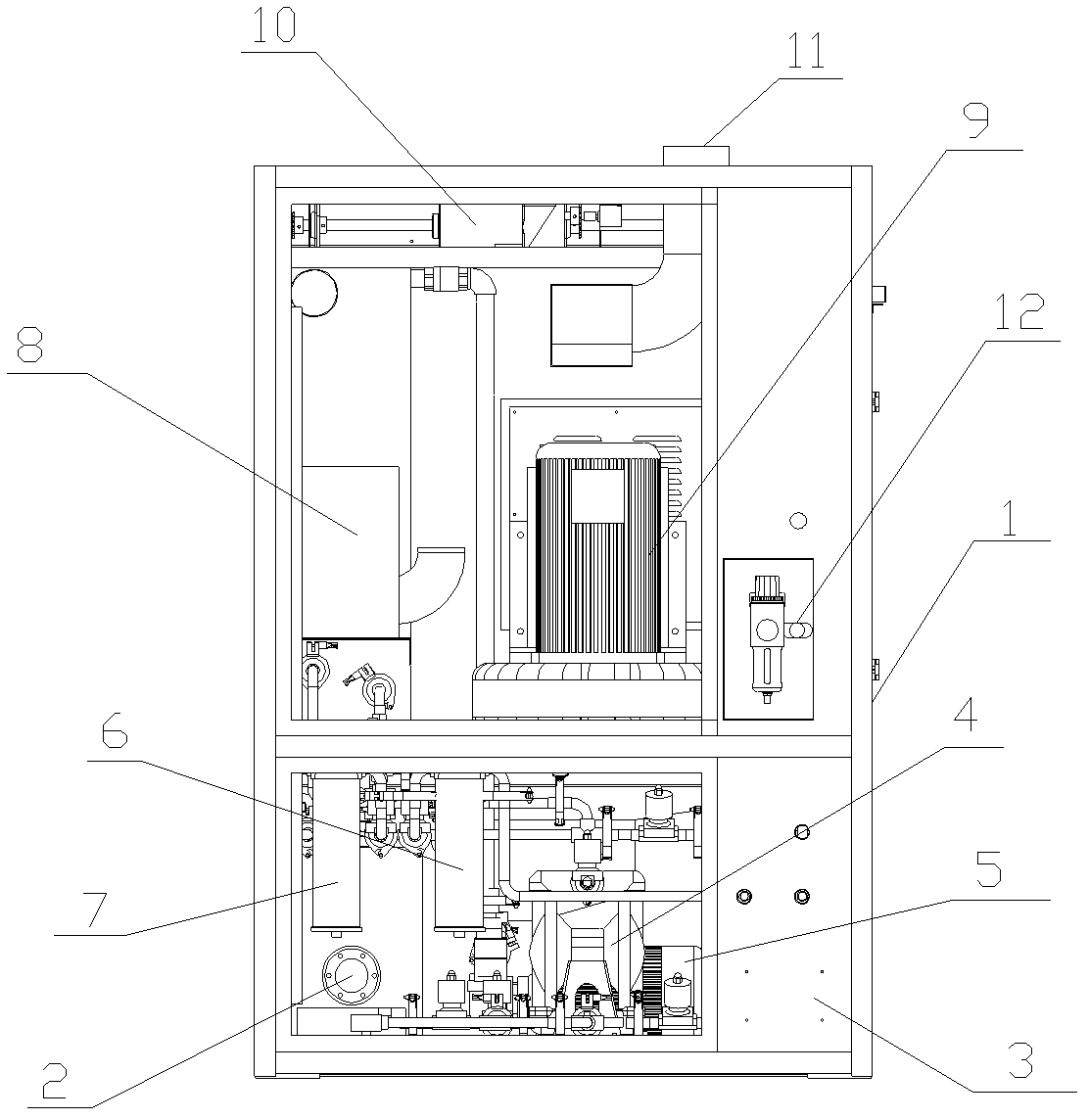

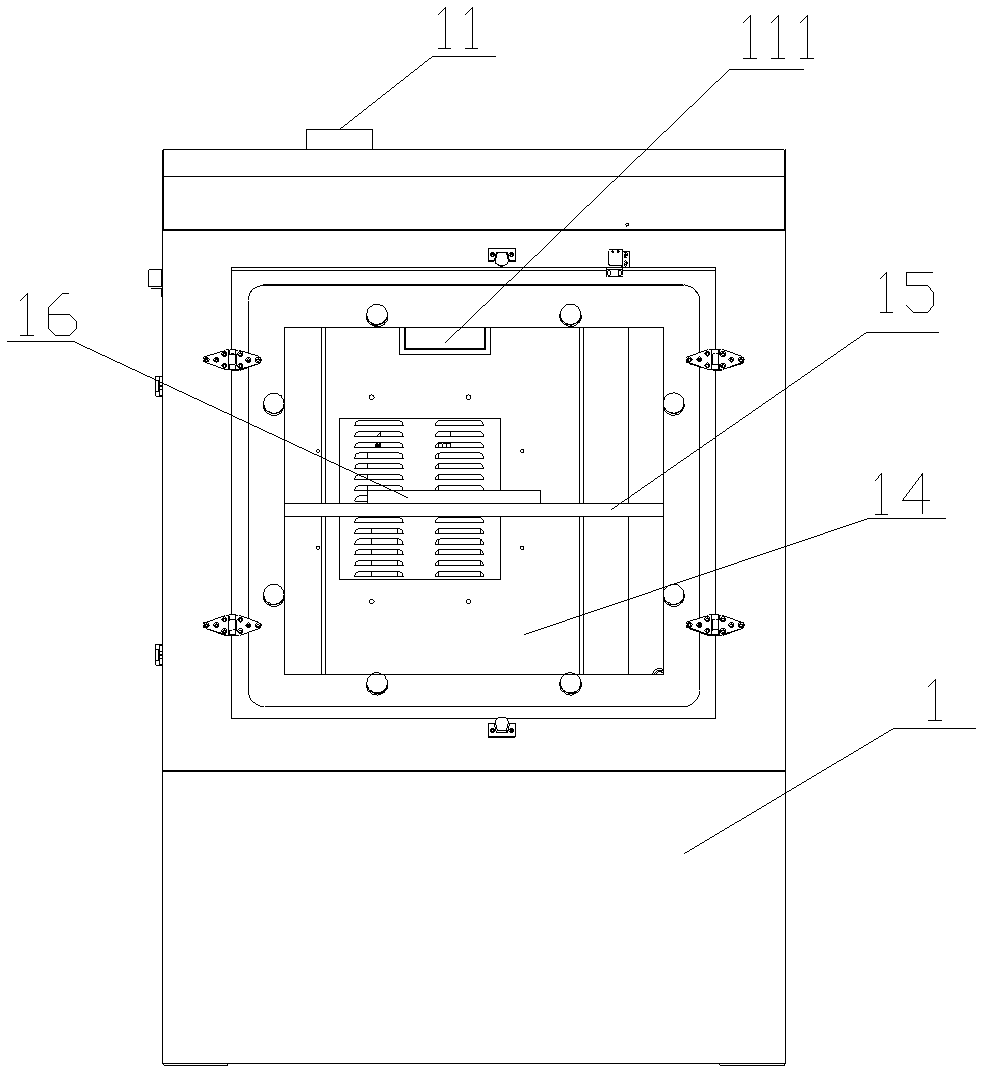

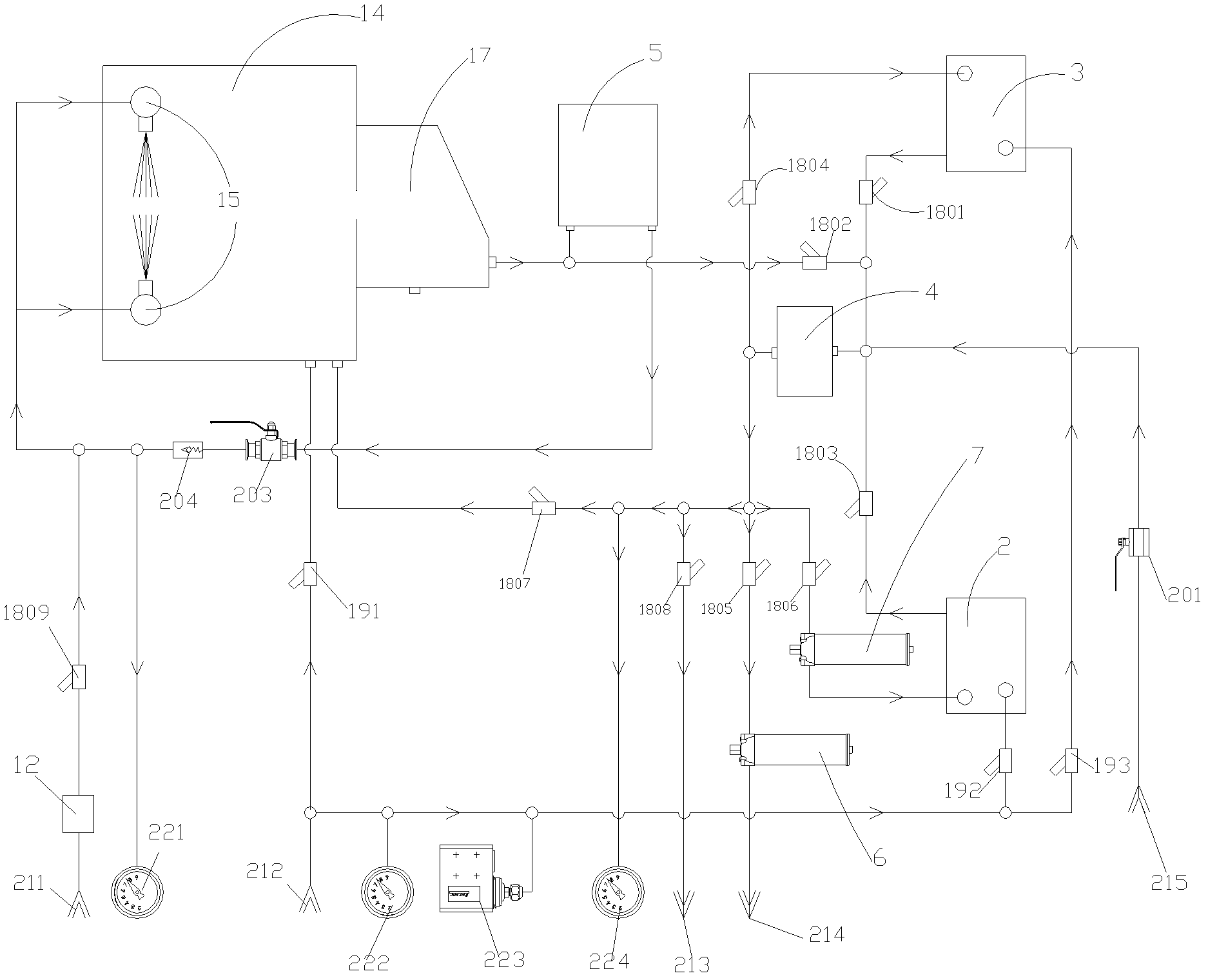

[0028] Such as figure 1 , figure 2 The shown water-based stencil cleaning machine includes a chassis main body 1, a cleaning solution tank 2, a rinsing solution tank 3, a pneumatic diaphragm pump 4, a water pump 5, a rinsing solution filtering device 6, a cleaning Liquid filtration device 7. The upper part of the chassis main body 1 is provided with a hot air box 8, a blower 9, a gear transmission 10, a pressure regulating filter 12, a spraying device 15, and a cleaning chamber 14, and the spraying device 15 is arranged inside the cleaning chamber 14. The upper surface of the chassis main body 1 is provided with an air outlet 11 , and the air outlet 11 communicates with the cleaning room 14 through a ventilation opening 111 provided on the inner wall of the cleaning room 14 . The bottom of the cleaning chamber 14 is provided with a spray...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com