Preparation method for coating decorative glass with crack coating

A technology for decorative glass and cracks, applied in special decorative structures, decorative arts, printing devices, etc., can solve problems such as lack of other elements, and achieve the effects of uniform film spreading, firm bonding and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

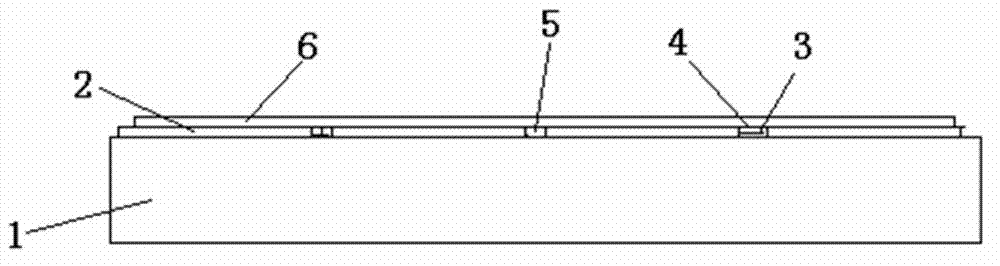

[0021] A kind of coated decorative glass with crack coating of the present invention and preparation method thereof comprise the following steps:

[0022] 1. The glass substrate is cleaned and dried;

[0023] 2. Screen printing ink pattern on the glass substrate,

[0024] 2.1 Directly print the pattern produced by voids or cracks on the printed pattern; the solid content of the ink is controlled at 25-30% (mass ratio)

[0025] 2.2 Or use heat treatment or ultraviolet curing to produce voids or crack patterns on the printed pattern; the solid content of the ink is controlled at 15-25% (mass ratio)

[0026] 2.3 The heat treatment temperature is determined according to the screen printing ink. The heat treatment temperature of low-temperature printing ink is below 140°C~260°C, and the heat treatment temperature of high-temperature printing ink is below 540°C~710°C; 385nm range 15KWh / m 2 , the preferred scheme is that the intensity of ultraviolet radiation from 280nm to 320nm i...

Embodiment 1

[0036] 1. The glass substrate is cleaned and dried; the solid content of the printing ink is controlled at 25-30% (mass ratio);

[0037] 2. Use screen printing heat-curing ink pattern on the glass substrate, and the pattern produced by the void or crack is directly printed in the pattern;

[0038] 3. The glass printed with low-temperature ink is heat-treated at 140°C~260°C for 5-15 minutes to cure the ink; the glass printed with high-temperature ink is heat-treated at 540°C-700°C for 2-5 minutes to cure the ink;

[0039] 4. Put the printed glass with cracks or voids into a vacuum environment, and use sputtering or thermal evaporation to coat the ink surface with a titanium oxide film first, and then coat it with a highly reflective material film. High reflective film materials include, plated silver, or stainless steel, or titanium, or silicon metal film layer; embedded in ink cracks or voids; the vacuum of the back of the film is lower than 10 -4 Pa; working coating vacuum i...

Embodiment 2

[0043] 1. The glass substrate is cleaned and dried; the solid content of the printing ink is controlled at 25-30% (mass ratio);

[0044] 2. Use screen printing heat-curing ink pattern on the glass substrate, and the pattern produced by the void or crack is directly printed in the pattern;

[0045] 3. The glass printed with low-temperature ink is heat-treated at 140°C~260°C for 5-15 minutes to cure the ink; the glass printed with high-temperature ink is heat-treated at 540°C-710°C for 2-5 minutes to cure the ink;

[0046] 4. Put the printed glass with cracks or voids into a vacuum environment, and use the sputtering method or thermal evaporation method to first coat the ink surface with a titanium oxide film, and then coat a highly reflective oxide material film. Highly reflective inorganic compound film materials include tin oxide, or niobium oxide, or stainless steel oxide, or titanium nitride, or chromium nitride film layer; the plated film layer is embedded in ink cracks or...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com