Fluorocarbon double-component coating with high weather resistance

A two-component, high weather resistance technology, applied in the direction of anti-corrosion coatings, coatings, etc., can solve the problems of poor construction performance, inability to meet the needs of anti-corrosion, poor weather resistance, etc., and achieve the effect of easy construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

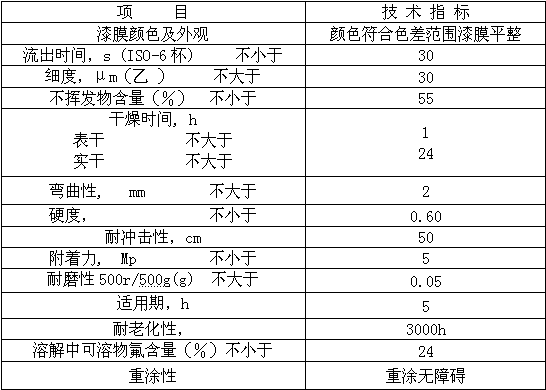

Image

Examples

Embodiment 1

[0045] The substance and weight percentage of A component are as follows:

[0046] Component A:

[0047] Polyisocyanate: 60

[0048] Butyl acetate: 20

[0049] Xylene: 20

[0050] Component B:

[0051] Fluorocarbon resin: 60

[0052] Titanium dioxide 30

[0053] Anti-settling agent: 1

[0054] Dispersant: 0.5

[0055] Leveling agent: 0.5

[0056] Defoamer: 0.5

[0057] UV absorber: 2.5

[0058] Methyl isobutyl ketone: 1

[0059] Butyl acetate: 2

[0060] Xylene: 2;

[0061] 1. Mix 60Kg of polyisocyanate, 20Kg of butyl acetate, and 20Kg of xylene in component A. After passing the inspection, filter and pack.

[0062] 2. In component B, 60Kg of fluorocarbon resin, 30Kg of titanium dioxide, 1Kg of anti-settling agent, 0.5Kg of dispersant, 0.5Kg of defoamer, 1Kg of methyl isobutyl ketone, 2Kg of butyl acetate, and 2Kg of xylene , mix evenly, use a sand mill to disperse until the fineness is ≤30μm, add 0.5Kg of leveling agent, 2.5Kg of ultraviolet light absorber, mix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com