Sweat stain resisting tidying method of hygroscopic and sweat releasing knit goods

A knitted fabric, moisture-absorbing and sweat-wicking technology, applied in the field of textile products, can solve problems such as easy to leave sweat stains, achieve the effect of maintaining the original characteristics, facilitating popularization and application, and improving brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0024] DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENTS The present invention will be further described in detail below in conjunction with examples.

[0025] An embodiment of the moisture-absorbing and perspiration-wicking knitted fabric anti-perspiration finishing method of the present invention, comprising such as

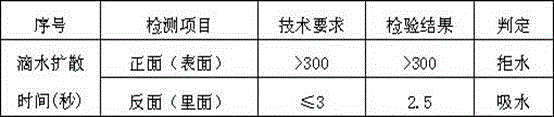

[0026] The following process flow: soft processing of knitted fabrics→sizing→processing of anti-sweat marks on the front of knitted fabrics→inspection of anti-sweat marks→baking.

Embodiment 1

[0028] With 14.8tex anti-stinky pulp fiber / cotton + 20DPU, the weight is 160g / m 2 The processing technology of the pink high-elastic single jersey of the present invention is used as an example, and the anti-perspiration finishing method of the present invention is used to organize it, and its technological process is as follows:

[0029] a. After dyeing, dehydrating and drying the above-mentioned cloth with a thickness of 0.5mm, it is rolled on a tenter frame with 6g / l non-ionic softener at 143°C to ensure the moisture absorption and perspiration effect.

[0030] b. Slurry mixing: The coating additives used should be prepared 24 hours in advance, and the single coating additives must be shaken evenly before use, and then the ingredients should be prepared. Use a beater to stir evenly for 15 minutes and then test the viscosity. It can only be used when the viscosity reaches about 10,000 centipoise. Sizing ensures that the water hardness is below 30PPM, the temperature of the ...

Embodiment 2

[0039] With 11.8tex bamboo pulp fiber / special-shaped polyester + 20DPU, the weight is 145g / m 2 The processing technology of the light green cotton wool knitted fabric is taken as an example, and the technology is as follows:

[0040] a. After dyeing, dehydrating and drying the above-mentioned fabrics with a thickness of 0.4mm, they are rolled on a tenter frame with 5g / l non-ionic softener at 140°C to ensure the effect of moisture absorption and perspiration.

[0041] b. Sizing: The coating additives used should be prepared 24 hours in advance. Single coating additives must be shaken evenly before use, and then batched. Stir evenly with a beater for 15 minutes to test the viscosity, and it can be used only when the viscosity reaches about 11,000 centipoise. Sizing ensures that the water hardness is below 30PPM, the temperature of the printing machine is kept at 165°C, and the weight percentage of the amount of compounding additives is:

[0042] Waterproofing agent EF-24 6% ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com