Inspection well sludge pipeline sucking and transporting method

A sludge and pipeline technology, applied in the field of pipeline transportation of non-Newtonian fluids, can solve the problems of difficult to achieve pipeline cleaning and transportation, and achieve the effects of reducing construction cost, shortening transportation distance, and overcoming viscosity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The embodiment is a method for sucking and transporting sludge in an urban manhole.

[0020] Urban manhole silt, which is neither solid nor liquid, belongs to the Bingham body category. This kind of sludge is in a plastic state and flowing state, and has the characteristics of smelly, sticky, soft, and black. In the past, there was no advanced suction method, and it has always been an urgent problem to be solved in urban development.

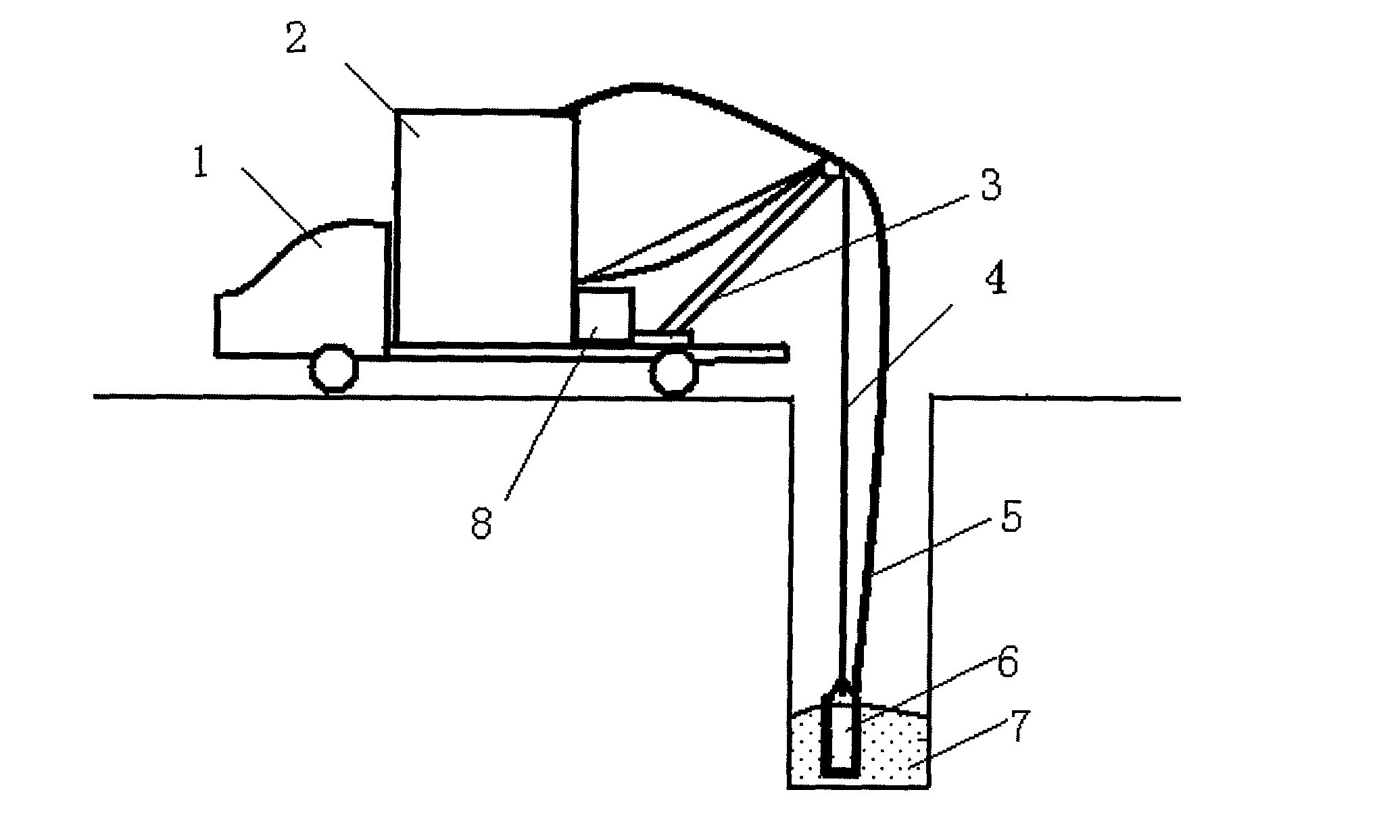

[0021] Such as figure 1 As shown, the carrier vehicle (1) is provided with a mud storage box (2), a crane (3), a control box (8), and a suction device (6) and an inspection well cover hook are hung on the crane (3) .

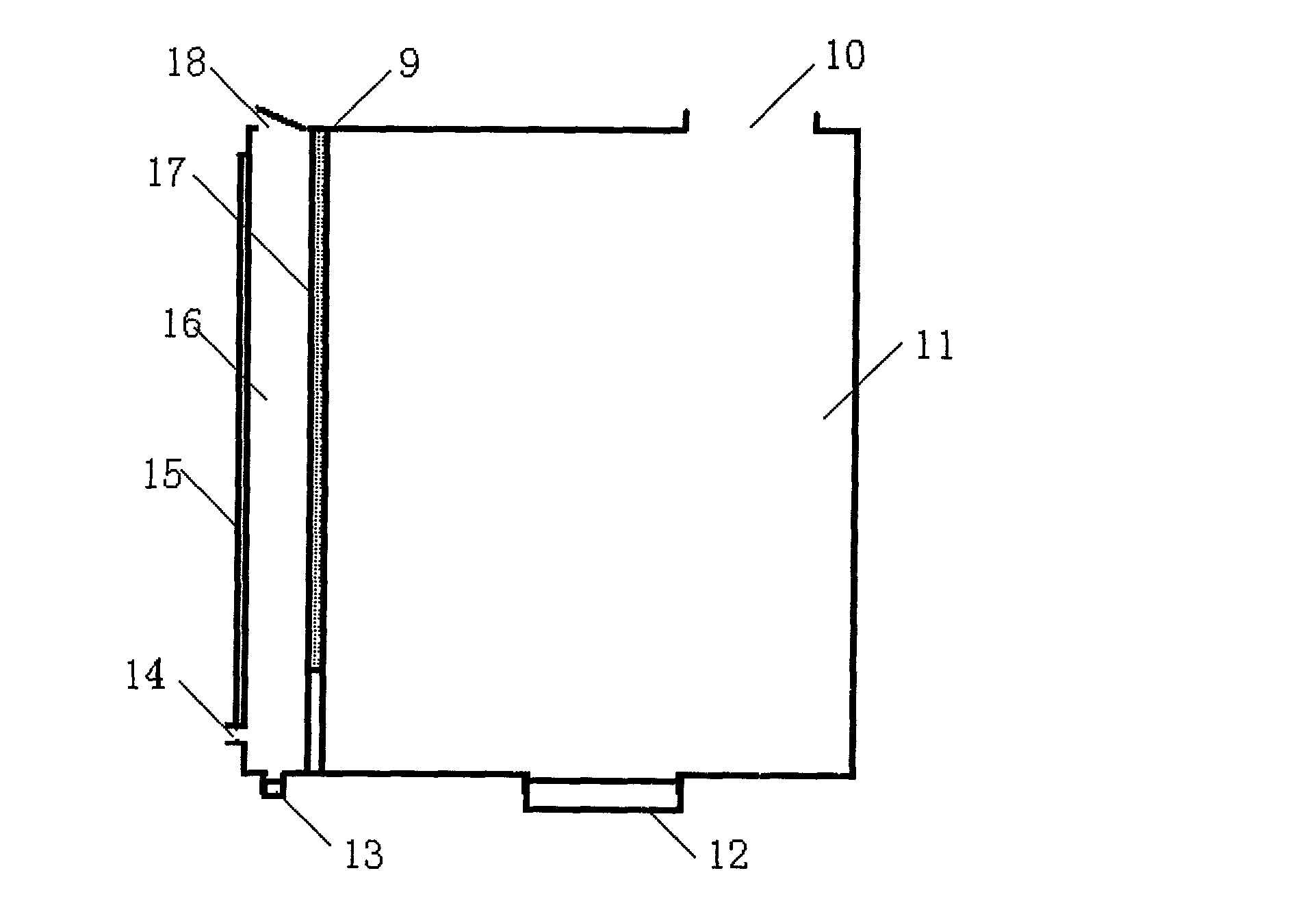

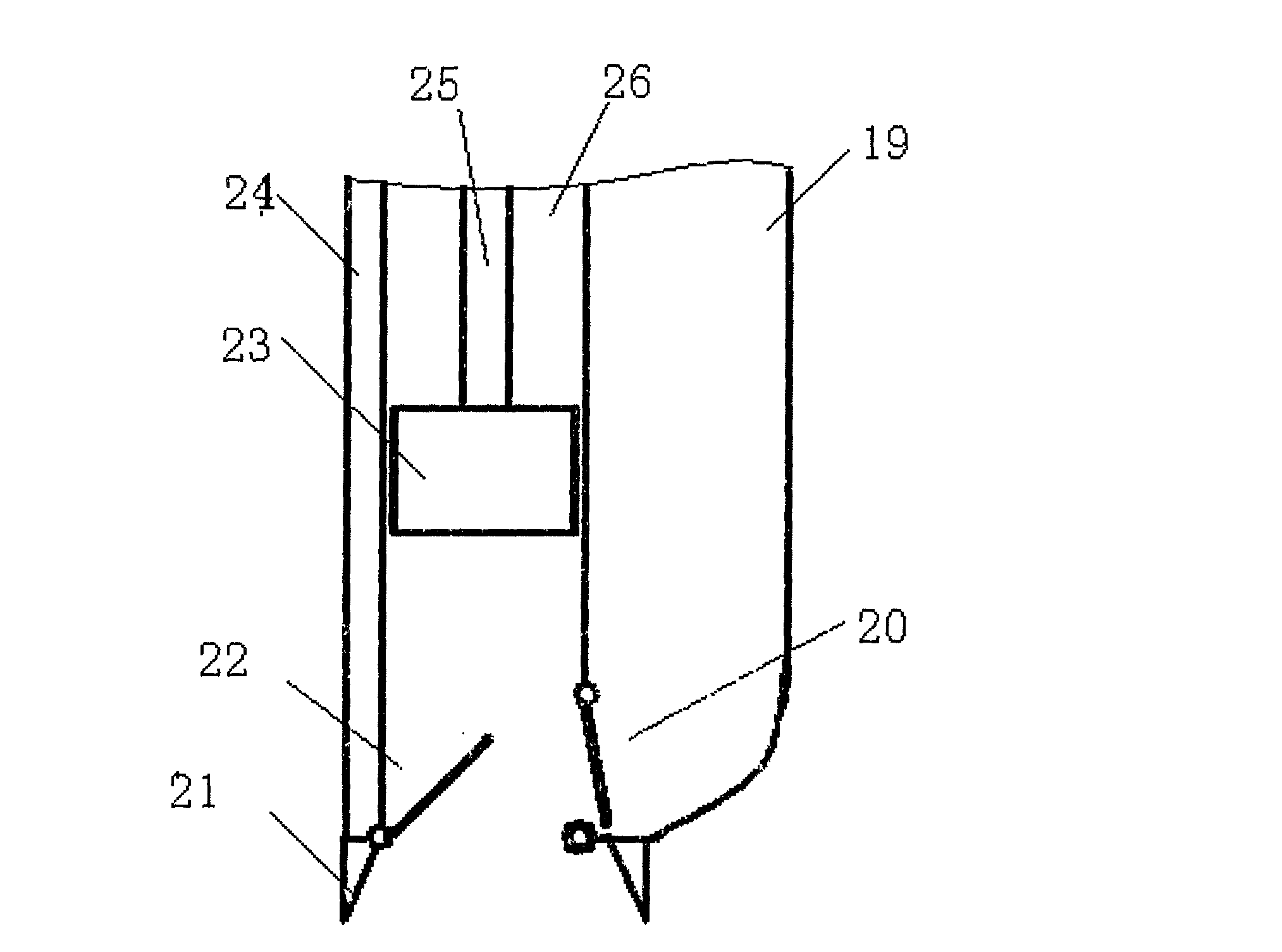

[0022] Suction device (6) includes: working cylinder (26), connecting rod (25), piston (23), mud inlet valve (22), mud outlet valve (20), mud suction port (21), mud passage (19) , liquid channel (24). There is a mud pipe (5) to be connected between the mud passage (19) of the suction device (6) and the mud box (11). Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com