Method and system of producing superheated steam

A superheated steam generation system technology, applied in steam generation methods, steam generation, steam generation devices, etc., can solve problems such as random adjustment, limited heating and adjustment capabilities, and inability to guarantee temperature, etc., to simplify manufacturing and installation time, manufacturing and the effect of shortening the installation time and reducing the probability of failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

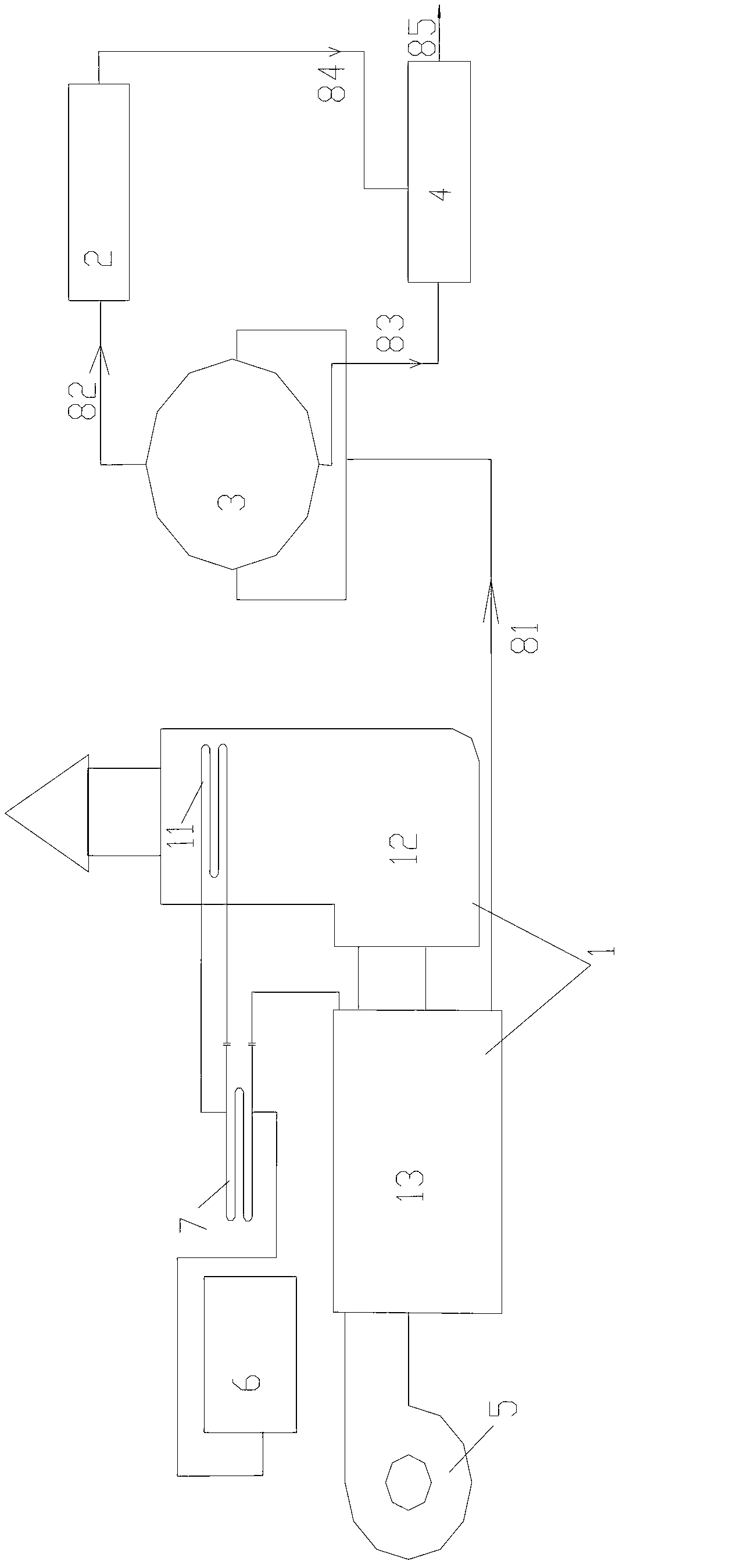

[0030] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

[0031] Such as figure 1 As shown, the present invention proposes a method for generating superheated steam, and the method for generating superheated steam includes:

[0032] Step A: introducing qualified demineralized water into the steam injection boiler 1 to generate wet steam 81 with a temperature of 350°C and a dryness of 75%;

[0033] Step B: Separating the wet steam 81 into steam and water to separate saturated water 83 and dry steam 82 with a dryness of more than 99%;

[0034] Step C: introducing the dry steam 82 into the secondary steam heater 2 for heating to obtain superheated dry steam 84 with a degree of superheat of 30° C. to 40° C.

[0035] The present invention uses the steam injection boiler and the secondary s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com