Laser with low-voltage driven electro-optical crystal

A technology of electro-optic crystals and lasers, which is applied in the field of lasers, can solve the problems of limited optical aperture, impossibility, and single distance, and achieve the effects of improving stability and service life, reducing manufacturing difficulty and cost, and reducing internal loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but the protection scope of the present invention should not be limited thereby.

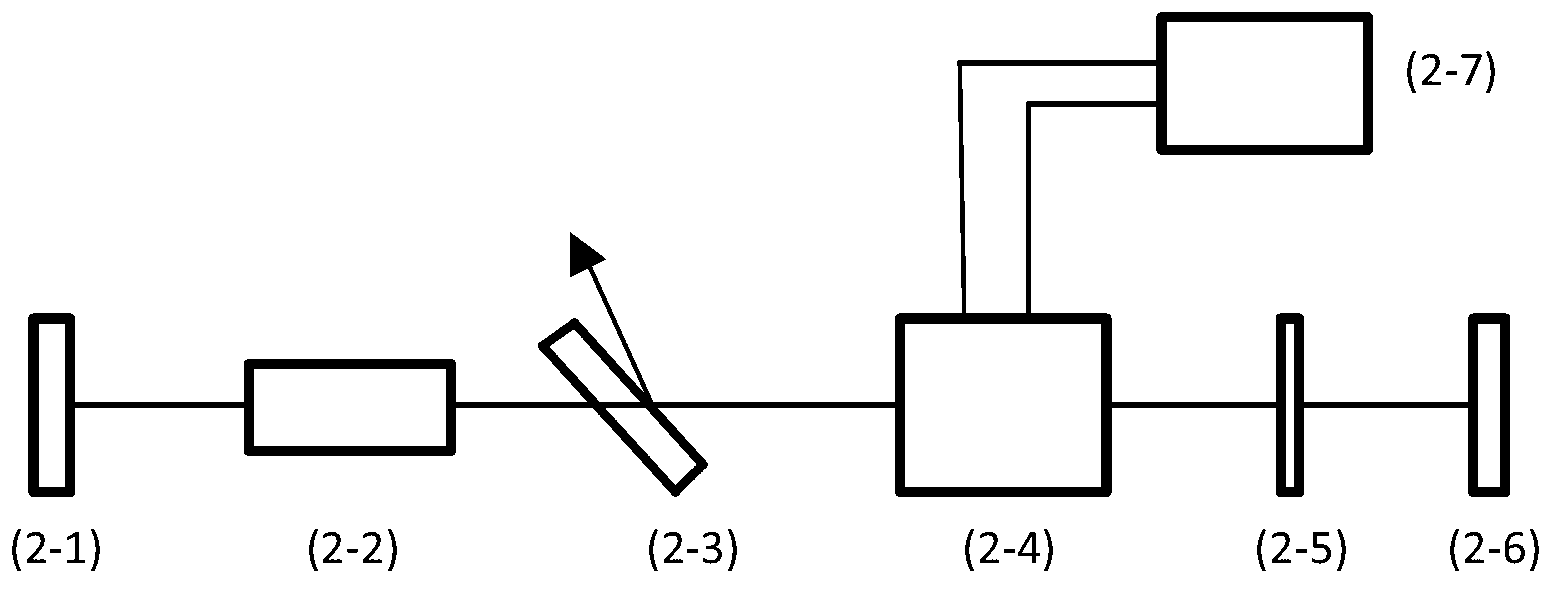

[0019] like figure 2 As shown, the low-voltage drive electro-optic crystal laser of the present invention comprises a first cavity mirror 2-1, a gain medium 2-2, a polarizer 2-3, an electro-optic crystal 2-4, and a wave plate 2 on the same optical axis in sequence. -5, the driving power supply 2-7 of the second cavity mirror 2-6 and the electro-optic crystal, the first cavity mirror 2-1, the gain medium 2-2, the polarizer 2-3, the electro-optic crystal 2-4, the wave Plate 2-5 and second cavity mirror 2-6 form a laser resonator, the polarizer 2-3 forms a certain angle with the optical axis, and the two ends of the electro-optic crystal 2-4 and the adjustable The driving power supply 2-7 is connected.

[0020] The laser light passes through the polarizer 2-3, passes throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com