Cage barrier spliced outer rotor stator electro-magnetic synchronous motor and control method thereof

A technology of rotor stator and synchronous motor, which is used in motor generator control, electronic commutation motor control, synchronous generator and other directions, can solve the problem of poor coupling effect of two sets of stator windings, complicated manufacturing process, and large-scale stator dual-winding AC motors. Application difficulties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0071] The present invention is described in detail below in conjunction with accompanying drawing:

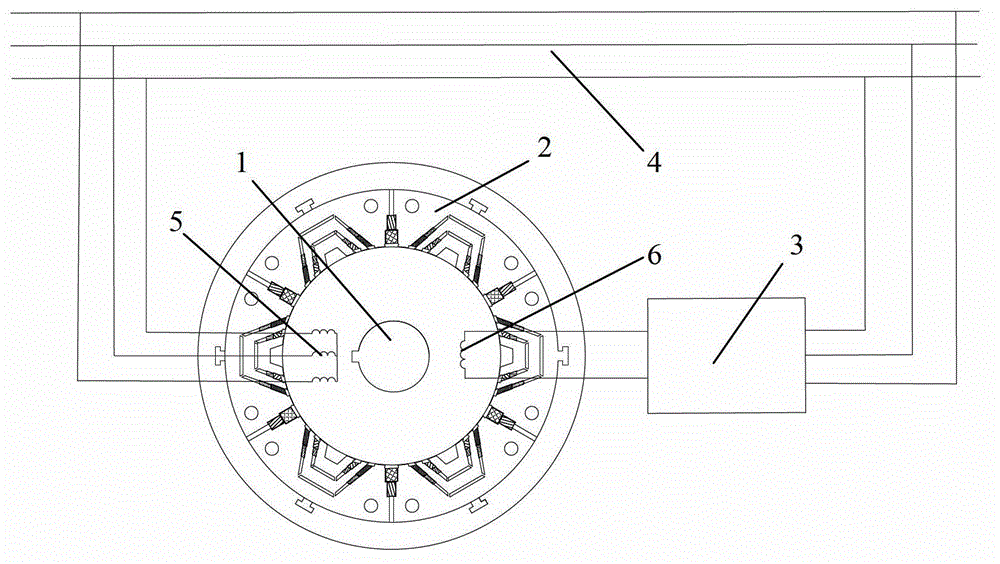

[0072] figure 1 It is a schematic structural diagram of the outer rotor stator electric excitation synchronous motor system with cage barrier assembly of the present invention. The system mainly includes a stator 1, an outer rotor 2, and a controllable DC power supply 3, wherein a three-phase symmetrical armature winding 5 with 2p poles is placed on the stator 1 and The single-phase symmetrical excitation winding 6 with 2q poles, the number of poles of the armature winding 5 and the number of poles of the excitation winding 6 can also be interchanged, but they all satisfy 2p-2q≥4, which can realize the electromagnetic coupling of two sets of stator windings with different pole numbers maximize. The armature winding 5 is connected to the grid 4 , and the field winding 6 is connected to one end of the controllable DC power supply 3 . The controllable DC power supply 3 provides...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com