Preparation method of sulfur-doped cobalt oxide and sulfur, nitrogen and oxygen-doped carbon in-situ composite electrode

An in-situ composite and cobalt oxide technology, which is applied to battery electrodes, circuits, electrical components, etc., can solve the problem of expensive rare metal materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

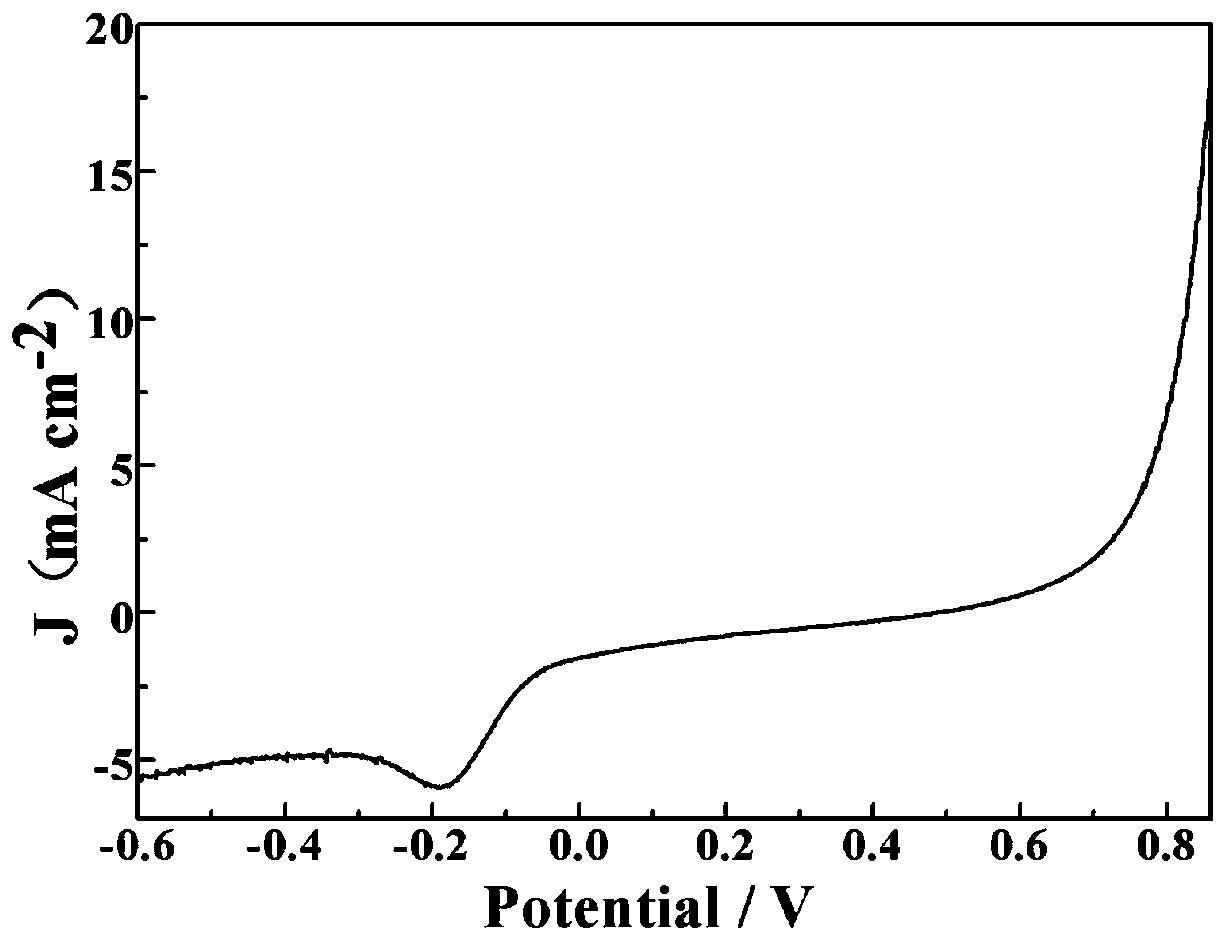

Embodiment 1

[0024] Electrodeposition was performed on carbon paper at room temperature with a cobalt nitrate concentration of 150 mM at a potential of −1.0 V for 90 s. After deposition, rinse repeatedly with deionized water and dry on a hot stage at 80°C for 10 min. Put the carbon paper deposited with sheet-like cobalt hydroxide arrays into a tube furnace, anneal in air at 400°C for 30 min, and cool naturally to room temperature. Take out the porous sheet-shaped cobalt oxide array in-situ electrode grown on the carbon paper. Tx-100 and thiourea were dissolved in 2.0 mL N,N-dimethylformamide solution to obtain a precursor solution, in which the amount of Tx-100 was 1.0 mL, and the concentration of thiourea was 2000 mM. Soak the porous cobalt oxide array in-situ electrode grown on carbon paper for 30 min, take it out, dry it on a hot stage at 80°C for 10 min, and then evenly drop the precursor solution on the carbon paper , and then continue to dry for 30 min. Put the coated carbon paper ...

Embodiment 2

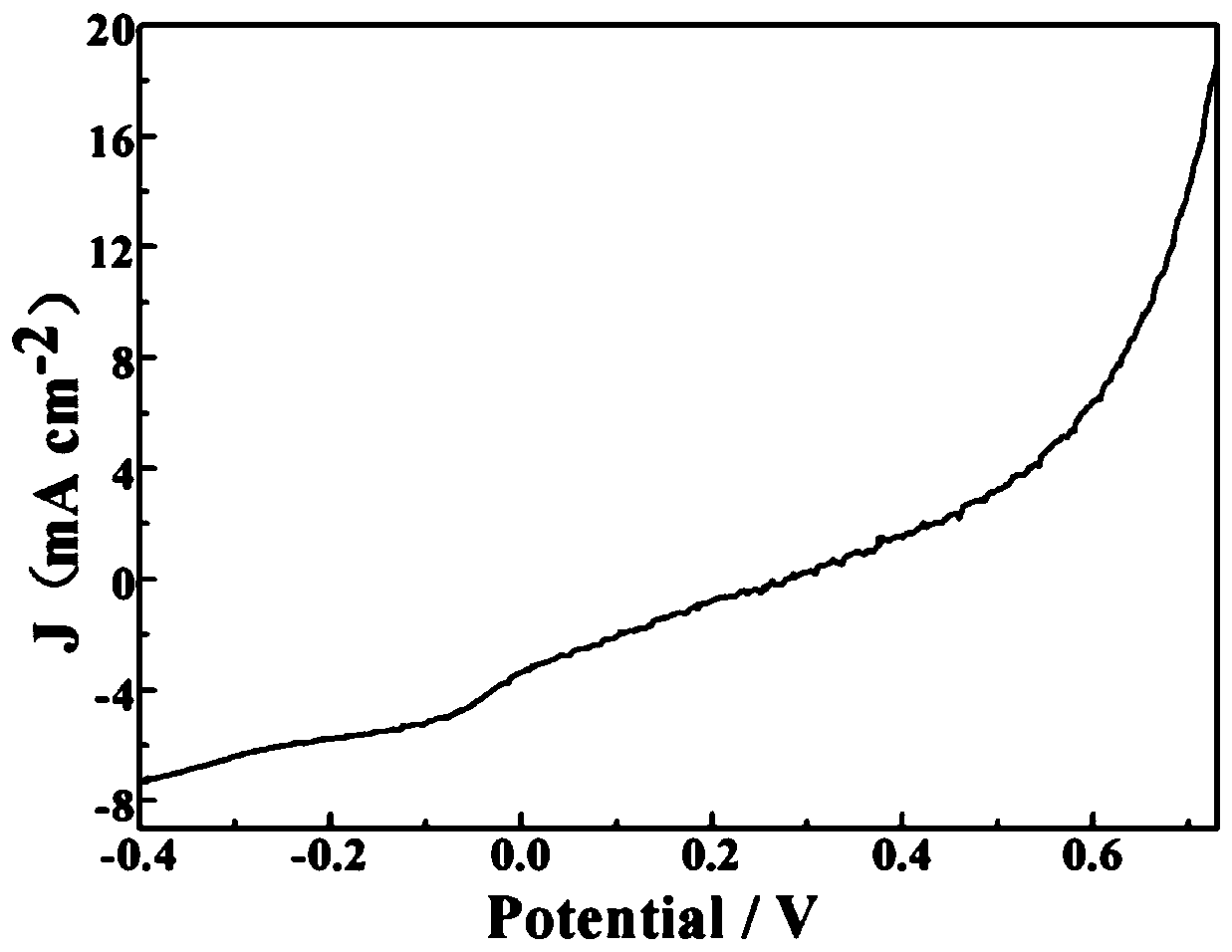

[0030]Electrodeposition was performed on carbon paper at room temperature with a cobalt nitrate concentration of 150 mM at a potential of −1.2 V for 90 s. After deposition, rinse repeatedly with deionized water and dry on a hot stage at 80°C for 10 min. Put the carbon paper deposited with sheet-like cobalt hydroxide arrays into a tube furnace, anneal in air at 400°C for 30 min, and cool naturally to room temperature. Take out the porous sheet-shaped cobalt oxide array in-situ electrode grown on the carbon paper. Tx-100 and thiourea were dissolved in 2.0 mL N,N-dimethylformamide solution to obtain a precursor solution, in which the amount of Tx-100 was 1.0 mL, and the concentration of thiourea was 2000 mM. Soak the porous cobalt oxide array in-situ electrode grown on carbon paper for 30 min, take it out, dry it on a hot stage at 80°C for 10 min, and then evenly drop the precursor solution on the carbon paper , and then continue to dry for 30 min. Put the coated carbon paper i...

Embodiment 3

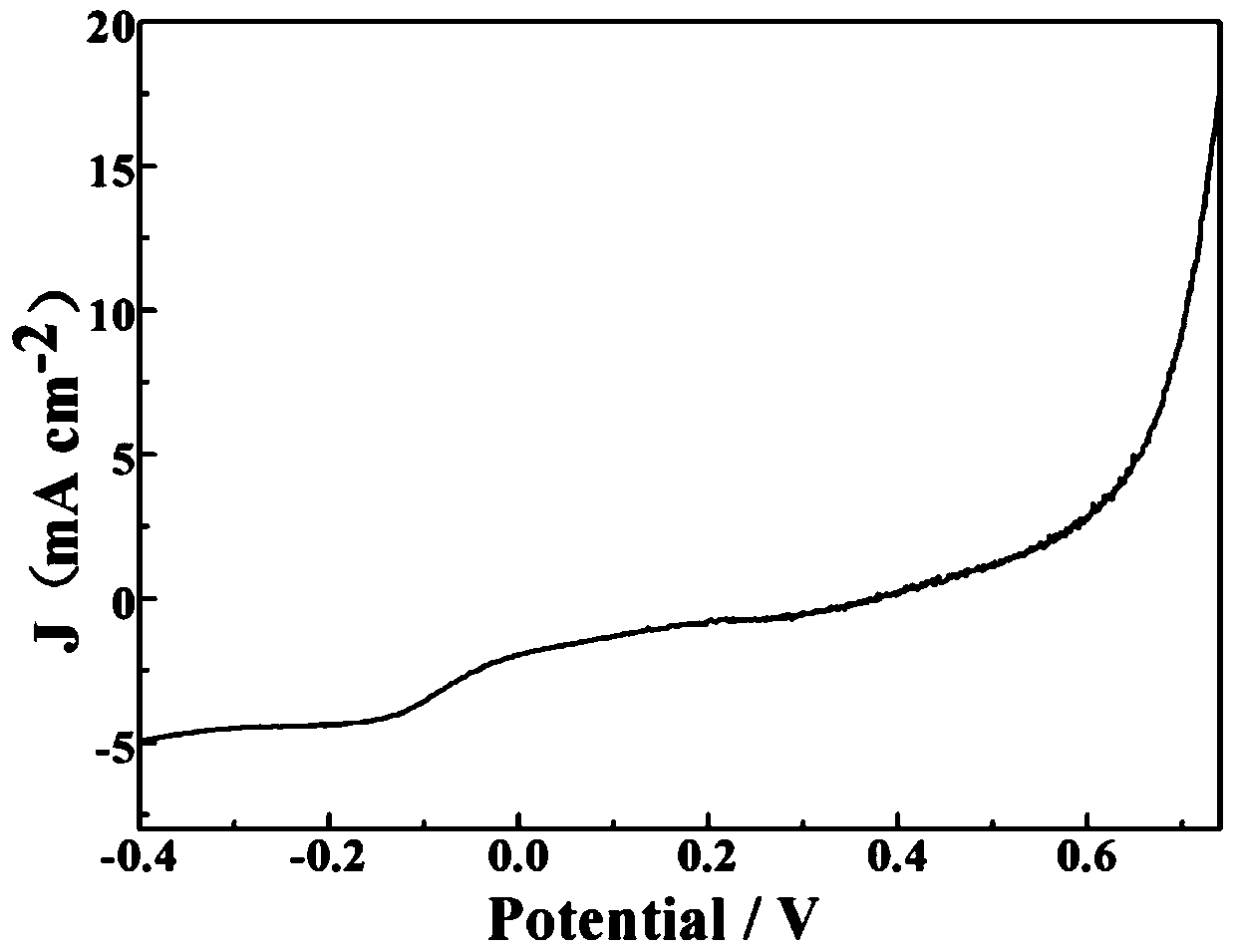

[0033] Electrodeposition was performed on carbon paper at room temperature with a cobalt nitrate concentration of 150 mM at a potential of −1.0 V for 180 s. After deposition, rinse repeatedly with deionized water and dry on a hot stage at 80°C for 10 min. Put the carbon paper deposited with sheet-like cobalt hydroxide arrays into a tube furnace, anneal in air at 400°C for 30 min, and cool naturally to room temperature. Take out the porous sheet-shaped cobalt oxide array in-situ electrode grown on the carbon paper. Tx-100 and thiourea were dissolved in 2.0 mL N,N-dimethylformamide solution to obtain a precursor solution, in which the amount of Tx-100 was 1.0 mL, and the concentration of thiourea was 1000 mM. Soak the porous cobalt oxide array in-situ electrode grown on carbon paper for 30 min, take it out, dry it on a hot stage at 80°C for 10 min, and then evenly drop the precursor solution on the carbon paper , and then continue to dry for 30 min. Put the coated carbon paper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com