Fungus culturing-developing method by central fungus seeding hole in tree segment

A cultivation method and technology for tree segments, which are applied in the field of cultivation of inoculation holes in the center of tree segments, can solve the problems of waste of resources, inability to large-scale production, and low efficiency, and achieve the improvement of the degree of mechanization, the full utilization of trees, and the simple process of inoculation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Fungus

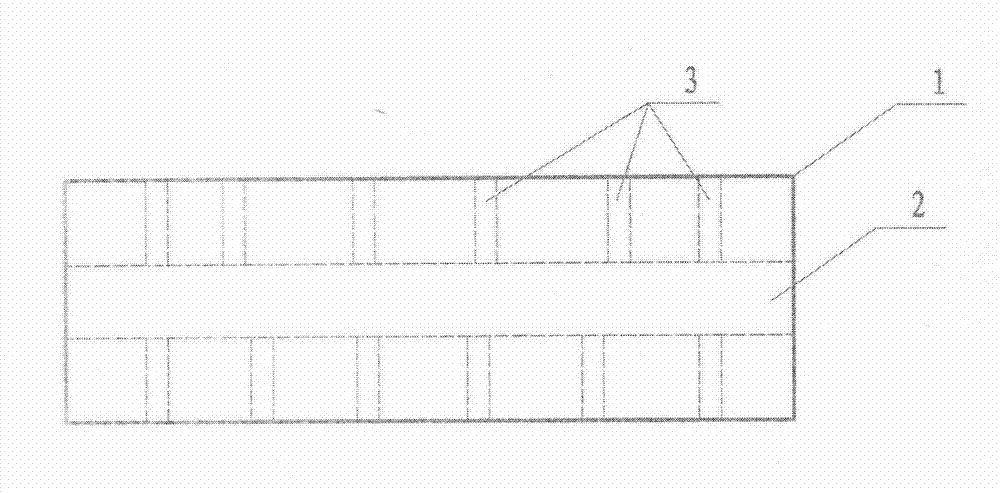

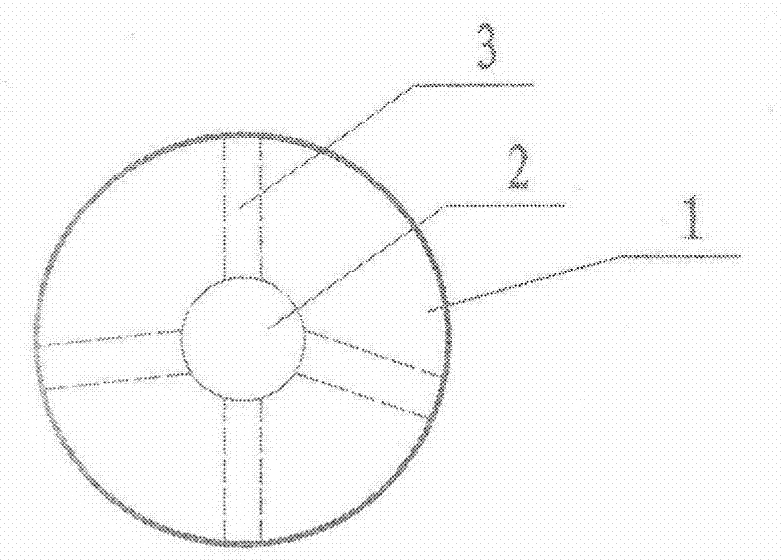

[0035] (1) Take a suitable tree segment 1, such as tussah, the length of tree segment 1 is between 30cm-2 meters, and the tree diameter is 2cm-15cm;

[0036] (2) Punch the central seedling hole 2 on the end face of the tree segment 1, that is, the cross section, with a diameter of 1cm-4cm; the central seedling hole 2 is a through hole, which penetrates the end faces of both ends of the tree segment. The center seed fungus hole 2 can also be punched from the two ends of the tree section to the middle of the tree section 1, leaving a distance of 1cm in the tree section 1 not to penetrate; or the center seed fungus hole 2 can be punched from one end of the tree section 1. , Has been close to the other end of the tree segment 1, leaving a distance of 1 cm in the tree segment 1 not to penetrate.

[0037] (3) Punch a number of fungal holes 3 on the surrounding surface of the tree section 1, with a diameter of 2cm-4cm; punch a plurality of holes on the surrounding surface o...

Embodiment 2

[0044] Shiitake

[0045] (1) Take tussah and other suitable shiitake mushroom tree segment 1, tree segment 1 is between 30cm-2 meters long, and the tree diameter is 2cm-15cm;

[0046] (2) Punch the central seeding hole 2 on the end face of the tree segment 1, ie the cross section, with a diameter of 1cm-4cm; the central seeding hole 2 is a through hole, which penetrates the end faces of the two ends of the tree segment 1. It is also possible to punch the center seed fungus hole 2 from the two ends of the tree section 1 to the middle of the tree section 1, leaving a distance of 1 cm in the tree section 1 not to penetrate; or the center seed fungus hole 2 from one end surface of the tree section 1. Strike, keep close to the other end of the tree segment 1, leaving a distance of 1 cm in the tree segment 1 not to penetrate.

[0047] (3) Punch a number of fungal holes 3 on the surrounding surface of the tree section 1, with a diameter of 2cm-4cm; punch a plurality of holes on the surroun...

Embodiment 3

[0054] (1) Take tussah and other suitable tree section 1 for straw mushroom growth, tree section 1 is between 30cm-2 meters in length, and the tree diameter is 2cm-15cm;

[0055] (2) Punch the central seedling hole 2 on the end face of the tree section 1, that is, the cross section, with a diameter of 1cm-4cm; the rest is the same as in Example 1;

[0056] (3) Punch a number of bacteria holes on the surrounding surface of the tree section 1, with a diameter of 2cm-4cm; the rest is the same as in Example 1;

[0057] (4) Use the central seed hole 2 as the seed hole, and sterilize the tree section under the right conditions, which can be sterilized by steam extinction. After sterilization, insert the rod into the central seed hole 2 for seeding, and then block the central seed hole 2. The punched hole is used as the center seed hole 2, insert the rod into the center seed hole 2, the rod contains the seed bacteria, and then the center seed hole 2 at the two ends o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com