Plastic packing box with laser light reflection effect and manufacturing method thereof

A manufacturing method and packaging box technology, applied in chemical instruments and methods, coverings/exterior coatings, layered products, etc., can solve the problems of no sun protection, no length, no water resistance, etc., and achieve flatness and surface gloss improvement. , good adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

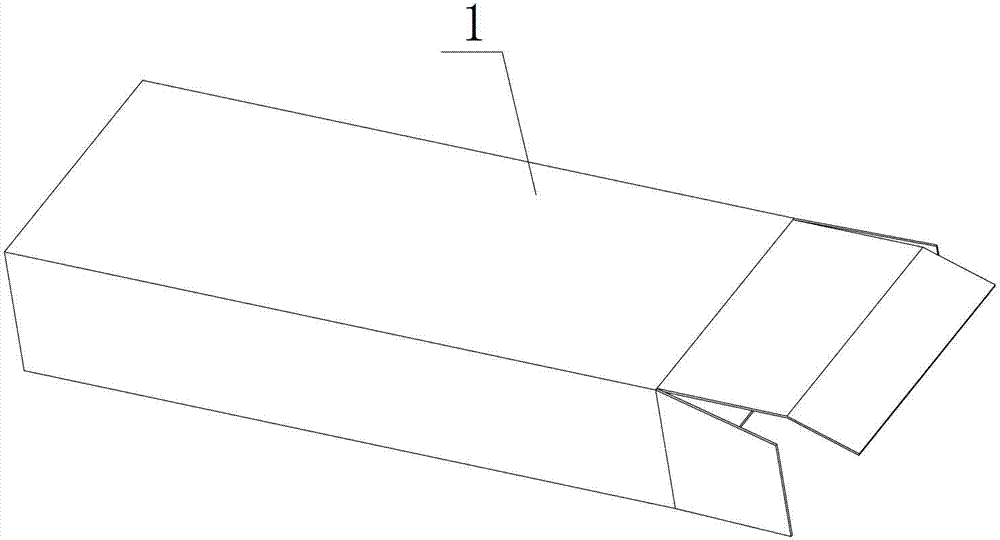

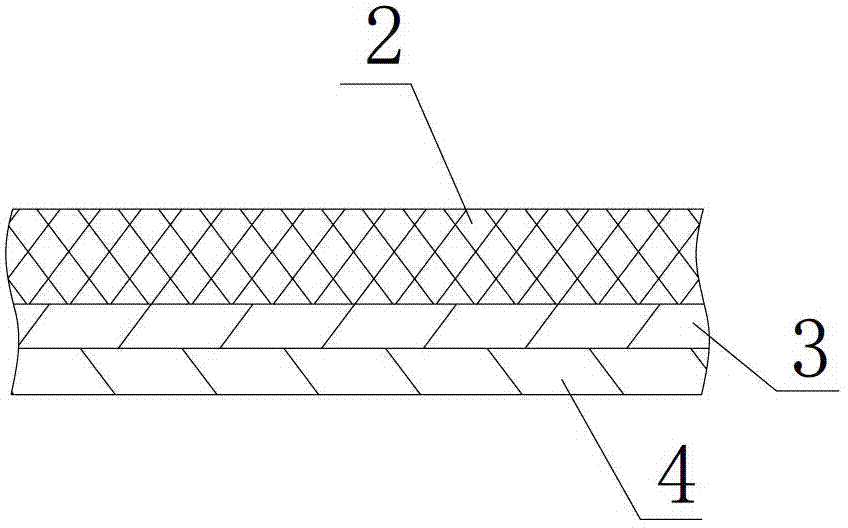

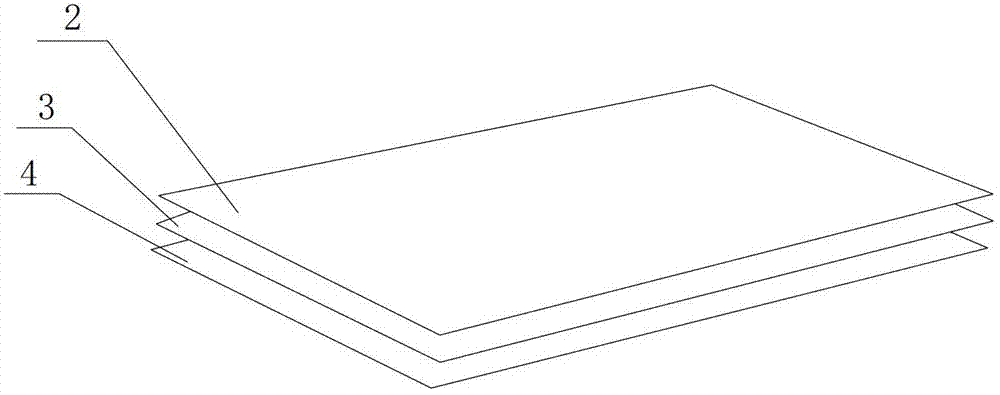

[0042] see figure 1 , figure 2 and image 3 , the cigarette packaging box is a packaging box for product display, which has high requirements on visual effects and service life. The cigarette packing box includes a box body 1 in the shape of a cuboid. A three-layer structure composed of layers 4, wherein the transparent plastic layer 2 is a transparent PVC layer made of PVC material, and the pattern layer 3 is printed on the inside of the transparent plastic layer 2, including cigarette names, trademarks, and promotional patterns. , text description, etc.; the laser reflective layer 4 is a laser film, and the laser film is an OPP laser film.

[0043] The manufacturing method of the above-mentioned plastic packaging box with laser reflection effect comprises the following steps:

[0044] (1) Utilize UV printing equipment and sunscreen ink to print patterns on the transparent plastic sheet, wherein, the transparent plastic sheet constitutes the transparent plastic layer o...

Embodiment 2

[0053] The plastic packaging box of this embodiment differs from that of Embodiment 1 in that the laser reflective layer 4 is composed of a metal coating in the laser film, specifically, the metal coating is an aluminum coating.

[0054] The difference between the manufacturing method of the plastic packaging box of this embodiment and that of Embodiment 1 is that in step (2), the metal coating on the laser film is embossed on the pattern layer of the transparent plastic plate by using an embossing device. The metal coating constitutes the laser reflective layer.

[0055] see Figure 4 , the embossing equipment mainly includes a film carrying device 5, a film conveying device 7, a laser film conveying device, a UV adhesive containing bucket 9, a UV adhesive conveying cylinder 10 arranged in the UV adhesive containing bucket 9, an embossing cylinder 11, UV lamp curing system 12, stripping device and film collection device 15, wherein, film carrying device 5 is used to stack th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com