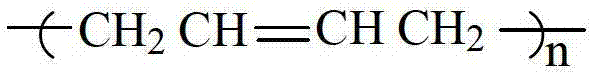

Preparation method of functional nickel-catalyzed cis-polybutadiene rubber anti-aging agent

A technology of butadiene rubber and anti-aging agent, which is applied in the field of anti-aging agent preparation, can solve the problems of increased Mooney viscosity, yellowing of appearance color, and increased gel content, and achieve good synergistic effect and good anti-tarnish performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

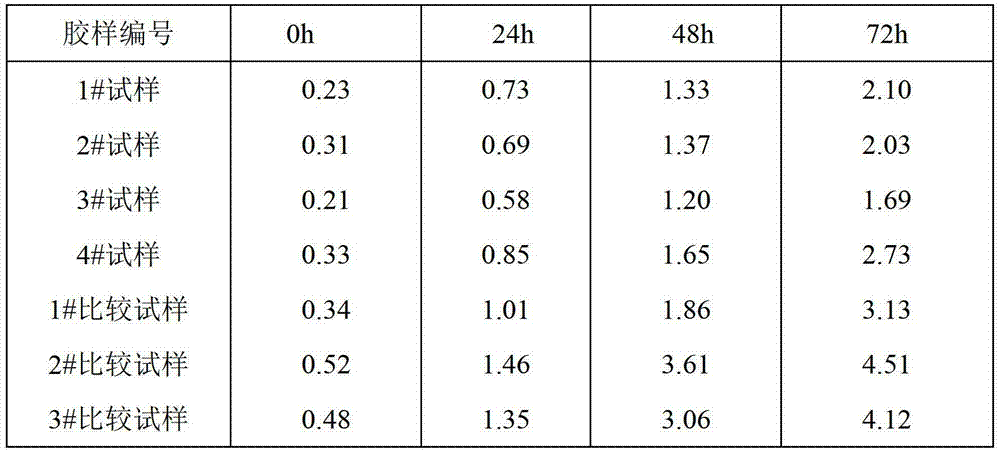

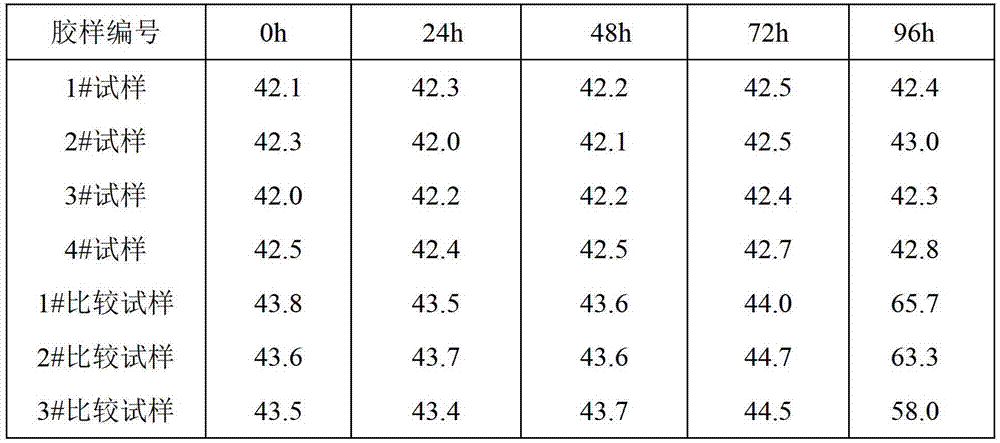

[0033] Weigh 25 grams of triethylene glycol bis-3-(3-tert-butyl-4-hydroxy-5-methylphenyl) propionate, 2,2'-methylene bis(4,6-di-tert-butyl phenyl) isooctyl phosphite 25 grams, bis (3-methyl-5-tert-butyl-4-hydroxybenzyl) sulfide 50 grams, antioxidant Irganox HP-13615 grams; add powder In the mixer, fully mix evenly, make anti-aging agent 1# sample of the present invention.

Embodiment 2

[0035] Weigh 25 grams of bis[β-(3-tert-butyl-4-hydroxy-5-methylphenyl)propionate] triethylene glycol ester, 2,2'-methylene bis(4,6-di-tert Butylphenyl) isooctyl phosphite 25 grams, two (3-methyl-5-tert-butyl-4-hydroxybenzyl) sulfide 50 grams, antioxidant Irganox HP-13610 grams; add powder In a body mixer, fully mix evenly, make the 2# sample of anti-aging agent of the present invention.

Embodiment 3

[0037] Weigh 25 grams of bis[β-(3-tert-butyl-4-hydroxy-5-methylphenyl)propionate] triethylene glycol ester, 2,2'-methylene bis(4,6-di-tert Butylphenyl) isooctyl phosphite 25 grams, bis(3-methyl-5-tert-butyl-4-hydroxybenzyl) sulfide 50 grams, antioxidant Irganox HP-13612 grams; add powder In the body mixer, fully mix uniformly, make antiaging agent 3# sample of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com