Construction method of XPS block body inner die super-thick long-span floor system

A large-span, block technology, applied in the direction of floor slabs, building materials processing, building components, etc., can solve the problems of easy breakage of the inner mold of the box, unfavorable installation works, exceeding the specification requirements, etc., to achieve non-breakable, balanced force, Guarantee the effect of construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

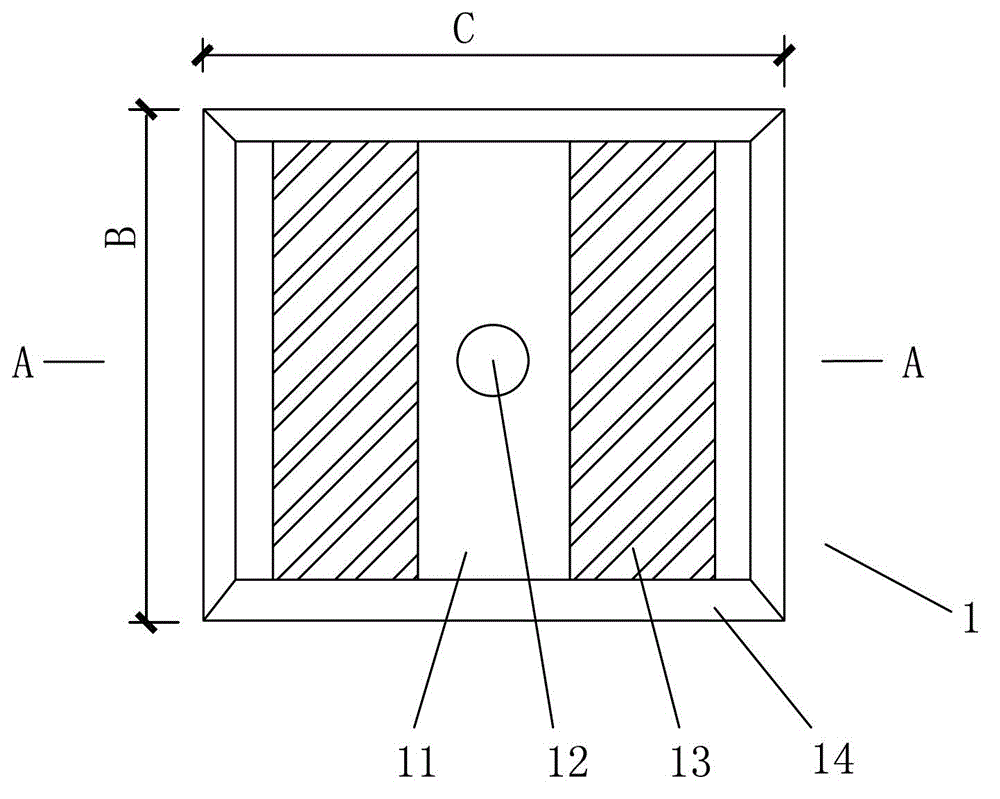

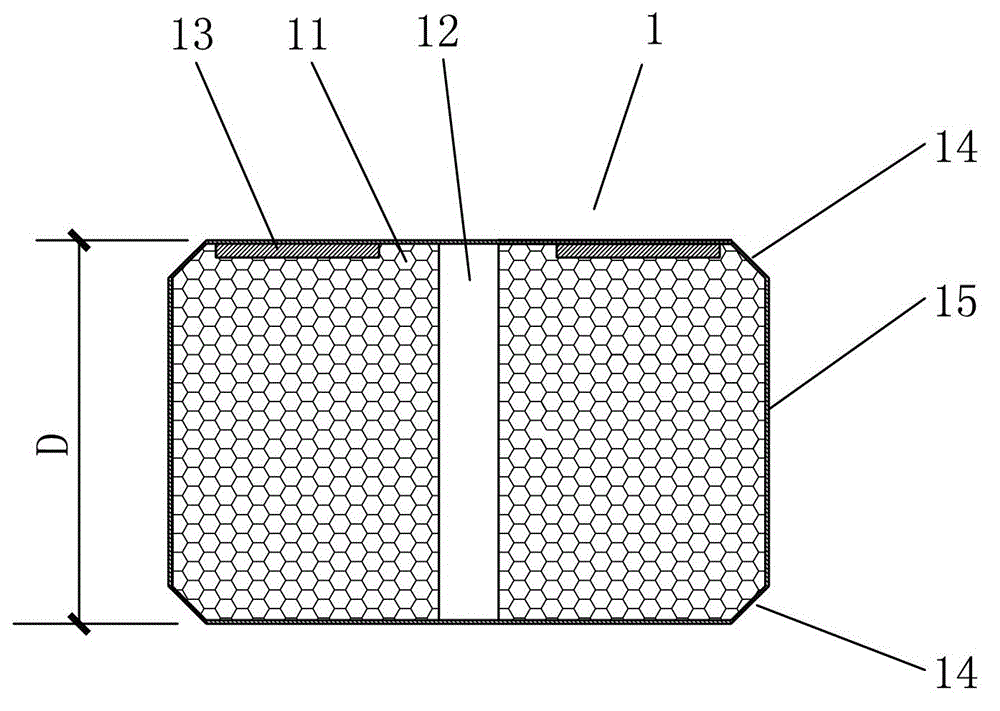

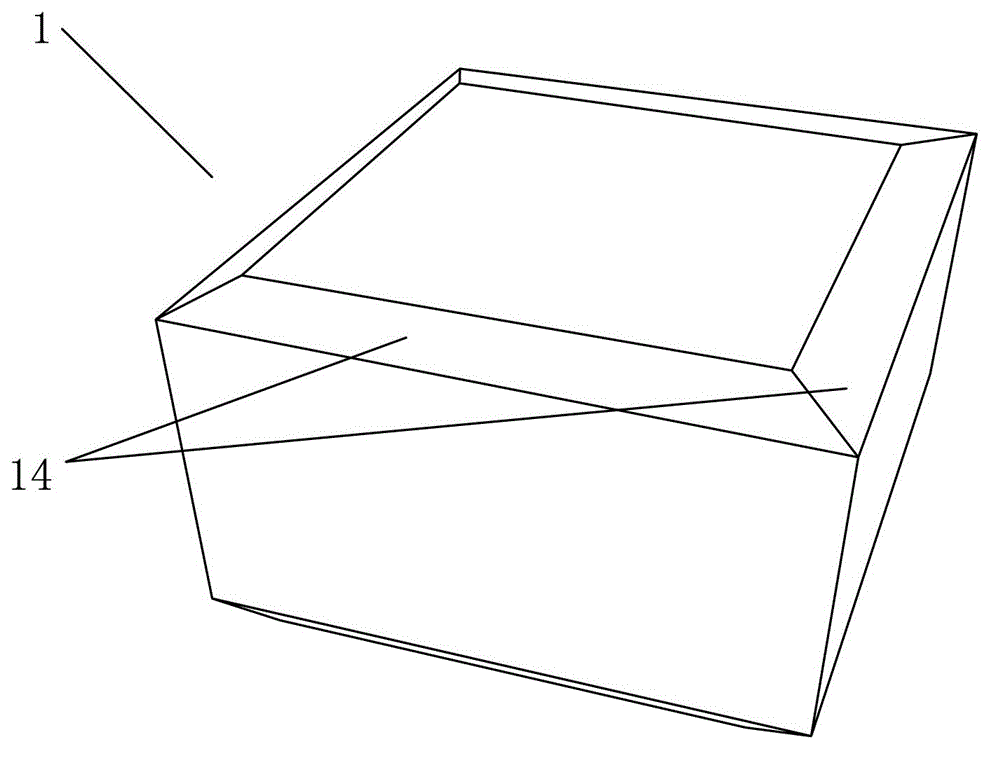

[0051] Below in conjunction with accompanying drawing, the present invention will be further described with specific embodiment, see figure 1 — Figure 8 :

[0052] The construction method of the ultra-thick and long-span floor of the XPS block internal mold, the construction method includes the following steps:

[0053] (1) Erection of the formwork frame: The erection method of the formwork frame 20 is the same as that of the ordinary formwork frame. Due to the large span and overweight structure, two points should be paid attention to in the erection of the formwork frame 20: First, the formwork frame scheme should be in accordance with the relevant national requirements Second, the floor structure should be arched according to the design requirements or 4 / 1000;

[0054] (2) Formwork support: The support method of formwork 8 is the same as that of ordinary formwork engineering. Since the bottom surface of the hollow floor is flat, the support of formwork 8 is much more con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com