Pressure bar device for maintenance-free energy-saving stove

A maintenance-free, lever-pressing technology, used in household stoves/stoves, household heating, lighting and heating equipment, etc., can solve problems such as inconvenience for chefs, large environmental pollution, easy entry of sludge and water, etc. Application value and promotion value, good energy saving effect and low environmental pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

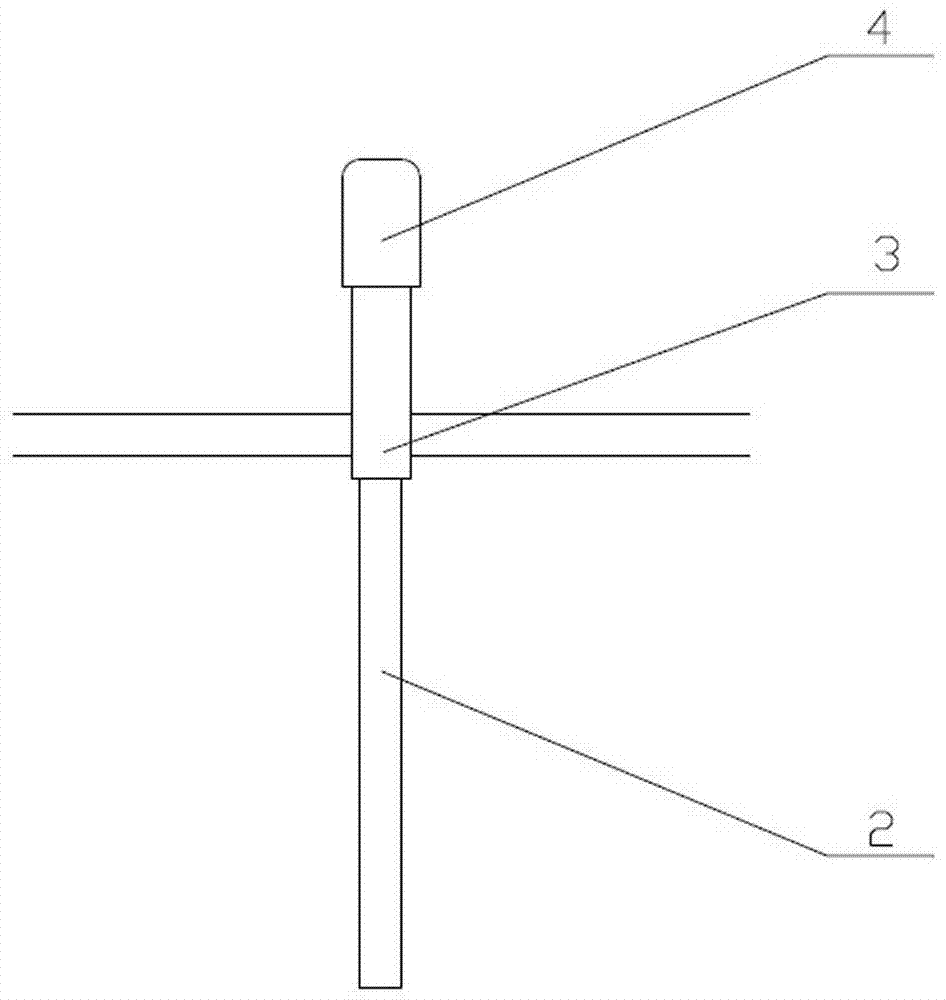

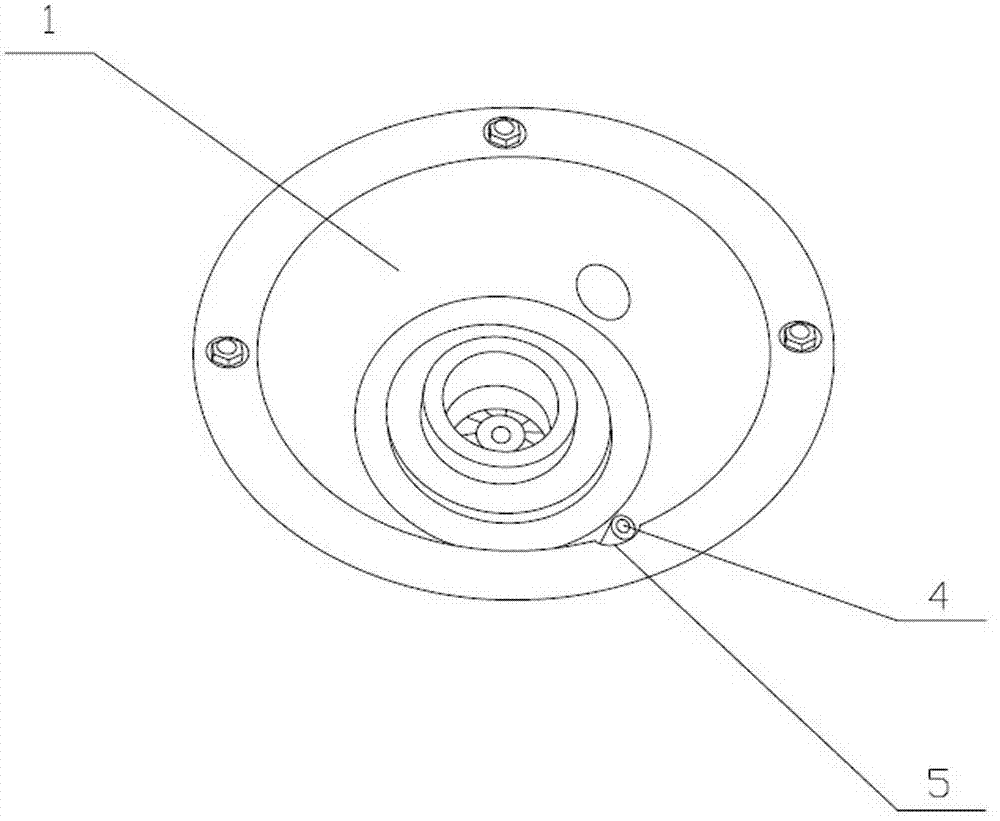

[0015] Such as figure 1 , figure 2 As shown, the pressure rod device of the maintenance-free energy-saving stove includes a vertically movable pressure rod 2 arranged on the integral cast iron furnace 1 for controlling the opening and closing of the gas, and at least part of the upper end of the pressure rod 2 protrudes from the integral cast iron furnace 1, the upper end of the pressure rod 2 is provided with a pressure rod cap 4 that can prevent impurities such as oil, mud and water from blocking the pressure rod 2.

[0016] The pressure rod cap 4 is a hollow cylindrical structure with a cover on the top; the outside of the pressure rod 2 is covered with a hollow tubular support rod 3, and the lower end of the pressure rod cap 4 does not expose the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap